Tsarin aikin shimfidar fuska na sassan filastik

Short Bayani:

Tsarin aikin bayan gida na sassan filastik ya hada da: Feshin feshin ruwa, Bugun Silkscreen, Fitar madubi, Bugun canja wurin Ruwa, Bugawar canja wuri mai zafi, Biyan wutar lantarki, Sanya ruwan sanyi, Zafafan Hotuna, Zanen Laser.

Hakanan ana kiran aikin gyaran bayan fuska na sassan filastik da kuma ado da sassan filastik Post aiki na sassan filastik muhimmin tsari ne don samun bayyanar samfuran inganci.

Kyakkyawan bayyanar da keɓaɓɓiyar samfurin kai tsaye yana tasiri mai siye da ji daɗin fahimta kuma ya sami sha'awar amfani. A lokaci guda, yana isar da bayyanannen samfurin da bayanin masana'anta ga abokin ciniki, don cin kasuwar.

Fasahar maganin farfajiyar sassan filastik ita ce ta fesa abin rufa a saman sassan kayan allura da buga haruffa, don kare bangarorin daga lalacewar waje / samun kyakyawan bayyani da bayanin samfurin kayan da aka gabatar wa abokan ciniki.

1. feshin farfajiya

Ana fesa sassan filastik da fenti don kare farfajiyar sassan daga saduwa kai tsaye da wasu abubuwa, kauce wa kaikayi / karce da kuma hada abu da iskar shaka, tsawanta rayuwar, da ma kawata bayyanar.

Ta hanyar matsin iska, bindiga mai fesawa ta watse a cikin kayan ado masu kyau da na daddawa, waɗanda za a iya amfani da su zuwa saman murfin. (Ana iya raba shi zuwa feshin iska, fesawa mara iska da yayyafa wutar lantarki, da sauransu).

Yawancin lokaci ana amfani da bindiga mai fesawa don fesawa gaba ɗaya akan abin, sa'annan fentin ya bushe kuma ya ƙarfafa shi ya zama fim mai wuya. Yana da ayyukan kariya, kyau da alama. Ana amfani dashi galibi a cikin motoci, jiragen sama, robobi, itace, fata da sauransu.

Ana amfani da fentin feshin farfajiyar cikin kayan lantarki, kayan lantarki, motoci da sauran kayayyaki da kayan aiki.

A. Fesa fenti na yau da kullun.

Fesa fenti na yau da kullun shine mafi ƙarancin fasahar feshi. Babban aikinta shine kare saman sassan da tsawanta rayuwar sabis da kuma ba da launi na ƙarshe zuwa saman sassan. Fenti na yau da kullun na iya canza launuka iri-iri don ba da samfuran samfuran. Fenti na yau da kullun na iya canza tasirin tasirin mai sheki daban-daban zuwa wani matsayi, amma don samun mafi kyawu. Degree da makama, kuma ana buƙatar ƙara UV spray ko Rubber spray a kai.

B. Fesa UV, Feshin Roba

Feshin UV da fenti mai feshi mai roba dukkansu fenti ne na gaskiya.

Fesa UV yana da juriya mai kyau, kuma zai iya samun mafi kyawu da walwala da jin daɗi fiye da fesa ruwan fenti na kowa. Yana da matakai uku na yanayin bita / tsaka tsaki / dumbness. UV spraying tsari ya dogara da UV haske warkar .UV Paint spray rumfa dole ne ya zama babban aji mai tsabta da ƙura-hujja.

Ana amfani da feshin roba don ƙirƙirar laushi mai laushi na roba ko fata a saman sassan.

Fenti na UV da fentin Rubber na bayyane ne, kuma dangantakar su da kayan filastik ba shi da kyau, don haka mafi yawansu suna buƙatar fesa fenti na fenti mai tushe azaman matsakaici kafin a fesa su, yawanci suna wakiltar launin samfurin.

C.Fenti mai gudana: Fenti mai jan hankali wani nau'in feshi ne na musamman. An fi dacewa da shi da launi na fenti mai ɗauke da ƙarfen ƙarfe mai gudana a cikin ramin ɓangaren ɓangaren ɓangaren don ƙirƙirar ɗakin kariya don ware tasirin tasirin igiyar lantarki tsakanin yanayin ciki da waje na samfurin.

D. Akwai abubuwa masu mahimmanci guda 3 don yin la'akari da ingancin zanen: 1. mannewa karfi 2. darajar launi 3. mai sheki

Matsayin inganci don kwalliyar kwalliya shine yanayin aiki.

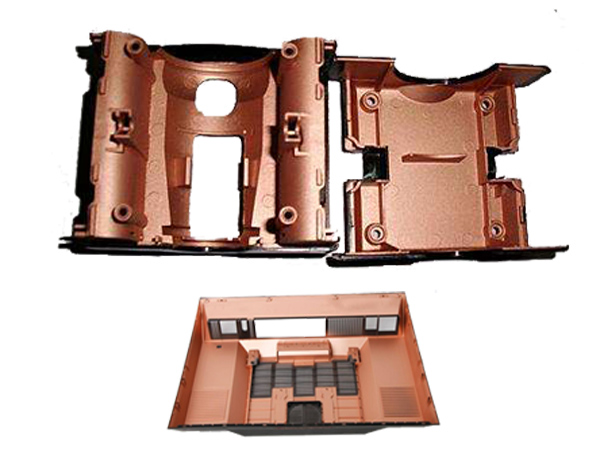

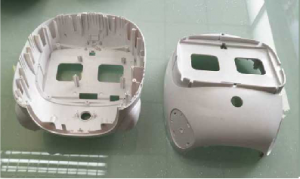

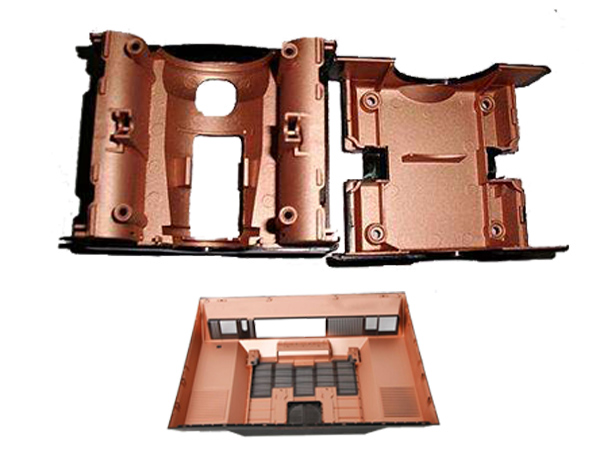

Sassan filastik tare da fentin farfajiyar da aka fesa :

2. buga allo da kuma adon ado

A. Bugun silks

Bugun silks shine hanyar da aka fi amfani da ita a saman samfuran filastik. Ya dace da tsarin bugawa akan jirgin ɗaukar kaya. A yayin bugawa, ana zuba tawada a ƙarshen ƙarshen farantin buga allo, kuma ana amfani da abin gogewa don yin matsin lamba a ɓangaren tawada na farantin buga allo. A lokaci guda, tawada na motsawa gaba ɗaya zuwa ɗaya ƙarshen ƙarshen faranti na allo. A cikin motsi, mai goge ya matse tawada daga ramin raga na ɓangaren hoto zuwa matattarar.

Bugun silks yana da manyan abubuwa guda biyar: farantin allo, zane, tawada, teburin bugawa da kayan kwalliya. Kayan aikin buga allo yana da sauki, baya bukatar kayan mashin, kuma galibi ana yin sa ne ta hanyar aikin hannu.

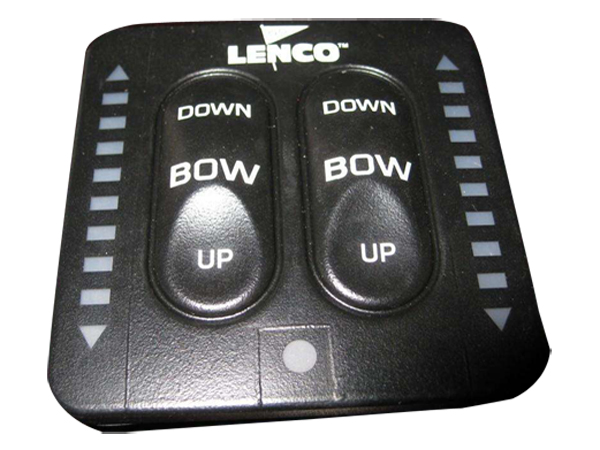

Rubutun B.Pad

Bugun Pad yana ɗayan hanyoyin bugawa na musamman. Yana iya buga rubutu, zane-zane da hotuna a saman abubuwa marasa tsari. Yanzu yana zama muhimmin bugawa na musamman. Misali, ana buga rubutu da sifa a saman wayoyin hannu ta wannan hanyar, kuma buga samfuran samfuran lantarki da yawa kamar mabuɗan kwamfuta, kayan kida da mitoci an kammala su ta hanyar canja wurin bugawa.

Saboda yana da fa'idodi a bayyane a cikin bugawa akan ƙaramin yanki, concave da convex kayayyakin, yana sanya nakasu da fasahar buga allo.

Kushin bugawa yana buƙatar inji na musanya na musamman, wanda yawanci ya ƙunshi na'urar farantin (ciki har da na'urar ciyar da tawada), zane-zane na tawada, kan biya diyya (yawanci kayan silica gel) da teburin bugawa.

Halin filastik tare da fesa fenti na yau da kullun

Halin filastik tare da fesa fenti na yau da kullun

UV spraying harka

Hannun fentin kwalliyar fenti

Silkscreened buga da kushin buga sassa :

3. Canja wurin bugawa

A. Bugun watsa ruwa

Bugun canja wurin ruwa sigar ado ce don kayayyakin filastik.

Hakanan ana kiran bugun canja wurin ruwa hydrographics ko hydroGraphics, wanda aka fi sani da bugawar nutsewa, bugawar ruwa, hoto canja wurin ruwa, dipping din ruwa, shigar ruwa ko kuma bugun ruwa mai siffar sukari, hanya ce ta amfani da zane-zane da aka buga zuwa bangarori masu girma uku. Ana iya amfani da tsarin aikin ruwa akan ƙarfe, filastik, gilashi, katako mai wuya, da sauran abubuwa daban-daban.

Fasahar canja wurin ruwa wani nau'in bugawa ne wanda yake amfani da matsi na ruwa don sanya hydrozeze takarda canja wuri / fim ɗin filastik tare da alamun launi. Tare da inganta kayan marufi da ƙa'idodin kwalliya, amfani da ɗab'in canja wurin ruwa yana da ƙari sosai. Tsarinta na kai tsaye kai tsaye da kuma cikakkiyar tasirin buguwa suna magance matsaloli da yawa na kayan kwalliyar kayan daki, galibi ana amfani dasu don canja wurin buga abubuwa daban-daban na yumbu, takarda fure na gilashi da sauransu.

Fasahar musayar ruwa tana da halaye masu mahimmanci guda biyu: na farko shi ne cewa ba'a iyakance shi da yanayin samfurin, musamman hadaddun ko manyan yankuna, ana iya yin ado da tsayi mai tsayi, da fadi-faɗi;

Sauran shine cewa shine mafi kyawun fasaha ga tsabtace muhalli. Sharar ruwa da ɓarnar ruwa ba za su gurɓata mahalli ba.

Amfani:

(1) Kyakkyawa: Zaka iya canza wurin kowane layi da hotuna, hotuna da fayiloli akan samfurin, don samfurin ya sami launi mai faɗi da ake so. Ya na da karfi mannewa da kuma sauran ilmi.

(2) Innovation: Fasahar canja wurin ruwa zata iya shawo kan matsalolin fasali mai rikitarwa da kuma mataccen kusurwa wanda baza'a iya samar dashi ta hanyar bugu na gargajiya da kuma canja wurin zafin jiki ba, canja wurin bugawa, buga allo da zanen farfajiya.

(3) Faɗawa: Ya dace da farfajiyar farfajiyar kayan masarufi, filastik, fata, gilashi, tukwane, itace da sauran kayayyaki (zane da takarda ba su dace ba).

Saboda kyanta, gama gari da kirkire-kirkire, tana da darajar kara aiki ga kayayyakin sarrafawa. Ana iya amfani da shi zuwa ado na gida, mota, kayan ado da sauran filayen, kuma yana da fasali iri iri, kuma ana iya amfani dashi tare da sauran sakamako.

(4) keɓance kai: duk abin da kuke so, na tsara kaina, kuma kowane irin tsari za a tsara shi tare da ku.

(5) Inganci: babu yin farantin karfe, zane kai tsaye, bugun canja wuri nan da nan (za a iya kammala aikin duka a cikin minti 30, mafi dacewar tabbatarwa).

(6) Fa'idodi: Tabbacin hanzari, bugun ƙasa, zanen launi na musamman da ba takarda da kuma zane mai zane tare da ƙananan alamu da yawa.

(7) kayan aikin suna da sauki. Ana iya yin sa a wurare da yawa waɗanda basa jituwa da zazzabi mai zafi. Babu wata bukata don siffar abin da aka sauya.

Kasawa:

Fasahar buga ruwa ta ruwa kuma tana da iyaka.

(1) Canja wurin hotuna da rubutu suna da sauƙaƙe, wanda ke da alaƙa da siffar samfurin da yanayin fim ɗin canja wurin ruwa da kanta. A lokaci guda, farashin ya fi girma, mafi rikitarwa kan aikin, ƙimar ya fi girma.

(2) Tsadar kayan aiki da tsadar kwadago.

B. Thermal canja wurin bugu:

Thermal canja wurin bugu ne mai fasaha da cewa kwafi juna a kan zafi-resistant biya diyya takarda, da kwafin juna na tawada Layer a kan gama abu ta dumama da kuma pressurizing. Koda don launuka masu launuka da yawa, saboda aikin canja wuri tsari ne kawai, abokan ciniki zasu iya gajarta aikin bugawa da rage asarar kayan (samfuran da aka gama) sanadiyyar kurakuran bugawa. Bugun tsarin polychromatic ana iya yin sa a lokaci ɗaya ta amfani da fim mai ɗebo zafi.

Amfani

(1) Tasirin bugawa yana da kyau, kyakkyawa sosai.

(2) Kayan kayan wucin gadi yayi ƙaranci, saurin samarwa yana da sauri, inganci yana da yawa.

Rashin amfani:

Samfurin yana buƙatar haɓakar zazzabi mai ƙarfi (bai dace da sassan filastik ba) kuma ana iya canza shi kawai a farfajiyar yau da kullun.

4. Fitar karfe

A. sanya wutar lantarki

Ana yin amfani da lantarki a cikin ruwa, don haka ake kiransa "electroplating na ruwa". Mafi yawancin mutane sune plating na jan karfe a saman filastik, nickel chromium, chromium trivalent, launin bindiga, nickel lu'u-lu'u da sauransu.

A ka'ida, dukkan robobi za a iya sanya su ta lantarki, amma a yanzu ABS, PC, ABS + PC ne kawai suka fi cin nasara, amma mannewar murfin lantarki a sauran robobin ba ya gamsuwa. Tsarin aikin zaɓar lantarki abu ne mai sauƙi kuma baya buƙatar fesa share fage kafin da bayan plating. Shafin yana da kyau mannewa, lokacin farin ciki da ƙananan farashi.

B. saka fanko

Injin plating yafi hada da injin danshin plating, sputtering plating da ion plating. Ana amfani da su duka don ɗora karafa daban-daban a saman ɓangarorin filastik ta hanyar ɓoyewa ko zugawa a ƙarƙashin yanayi na danshi.

Fim ɗin da ba na ƙarfe ba, ta wannan hanyar zai iya zama murfin shimfiɗar bakin ciki sosai, kuma yana da fa'idodi na musamman na saurin sauri da mannewa mai kyau, amma farashin ma ya fi haka, galibi ana amfani da shi don kwatankwacinsa, aikin rufi na aiki don samfuran ƙarshen zamani.

Za'a iya amfani da murfin injin a cikin robobi kamar su ABS, PE, PP, PVC, PA, PC, PMMA, da sauransu.

Za'a iya yin amfani da kayan kwalliyar inkila tare da nau'ikan karafa, kamar su aluminium, azurfa, tagulla da zinare, waɗanda suke da maɓallin narkewa fiye da wayar tungsten.

Kwatanta tsakanin lantarki electroplating da injin plating:

(1) Vacuum plating tsari ne na sutura a cikin layin fesawa da wutar makera, yayin da aikin samar da wutar lantarki tsari ne a cikin ruwa mai ruwa-ruwa. Saboda yana fesa fenti, kwalliyar kwalliya ba ta dace da samfuran fasali mai rikitarwa ba, yayin da aikin samar da wutar lantarki ba shi da takurawa ta hanyar fasali.

(2) Fasahar sarrafawa, kamar rufin rufin manne filastik, ana iya taƙaita ta kawai: lalacewar ƙasa na asali, dedusting, electrostatic hazo, fesa turaren UV, maganin UV, ƙarancin rufi, dedusting, fesa farfajiyar ƙasa (za'a iya ƙara maida hankali kan launi) , warkarwa, kayayyakin da aka gama; coatingarfin ruɓaɓɓen iska yana iyakance ta tsari, kuma bai dace da sarrafa samfuran tare da yanki mai girma ba saboda aiki. Tsarin fasaha ba shi da iko sosai, kuma ƙimar mummunan abu tana da yawa.

Roba electroplating (gaba daya ABS, PC / ABS): sunadarai deoiling hydrophilic coarsening raguwa preimpregnation palladium kunnawa hanzarin electroless nickel plating hydrochloric acid kunnawa coke jan ƙarfe sulfuric acid kunnawa Semi-haske nickel nickel sealing chromium plating bushe kayayyakin.

(3) ruwa da wutar lantarki plating za a iya kammala a cikin cikakken sarrafa kansa samar.

(4) gwargwadon bayyanar damuwa, launin haske na fim ɗin aluminized yana da haske fiye da na wutar lantarki mai sanya chromium.

(5) Dangane da yin aiki kuwa, kwalliyar kwalliyar filastik ita ce shimfidar waje ta waje, yayin da wutar lantarki yawanci sinadarin chromium ne na ƙarfe, don haka taurin ƙarfe ya fi na resin;

Amma game da juriya na lalata, ana amfani da murfin fenti yawanci. Layer murfin ta fi ta ƙarfe kyau, amma akwai ɗan bambanci kaɗan a tsakanin su a cikin buƙatun samfurin ƙarshe; a yanayin yanayi, zafin samar da wutar lantarki ya fi abin ɗaki, saboda haka yawanci yana buƙatar amfani na waje na dogon lokaci tare da juriya na yanayi.

A cikin masana'antar kera motoci, akwai kuma tsauraran buƙatu na juriya da zafin jiki na ƙasa, zafi da zafi, shafa mai da sauran su.

6) Ana amfani da plating vacuum a masana'antar sadarwa ta lantarki, kamar harsashi na wayar hannu, aikace-aikacen mota, kamar kofunan nuna fitilun mota; ruwa galibi galibi ana amfani dashi don chromium na ado, kamar kayan ƙofar mota. Orofofin ƙofa da sauransu.

(7) Dangane da yanayin bayyanar launuka iri-iri, kwalliyar kwalliya ta fi wadatar ruwa ruwa. Za'a iya yin ɗakunan zinare zuwa zinare da sauran launuka masu launi.

(8) gwargwadon farashin sarrafawa, farashin tsabtace yanayi yana sama da na plating na ruwa.

(9) Sharar faranti tsari ne na kare muhalli mai kore tare da ci gaban fasaha mai sauri, yayin da zaɓin zaɓin ruwa tsari ne na gargajiya tare da gurɓataccen gurɓataccen yanayi, kuma masana'antar tana iyakance ta tasirin manufofin ƙasa.

(10). Anan ga takaitaccen gabatarwar aikin feshi (aikin madubin azurfa) wanda ya fito yanzu. Tsarin shi ne rage gurɓataccen filastik da kayan share fage na musamman na nishaɗi na Nano-fesa ruwan tsarkake ruwa.

Wannan fasaha na iya haifar da tasirin madubi akan fuskar filastik. Hakanan tsari ne mai tsabtace muhalli.

Tsarin farko da na ƙarshen sune iri ɗaya da zaran injin buɗaɗɗen wuri, amma tsaka tsaka kawai.

An maye gurbin Alminin ta madubin feshin azurfa, amma aikin fasaha na yanzu na wannan aikin ba za a iya kwatanta shi da zanen ruwa da abin ɗaki ba. Ana iya amfani da shi ne kawai zuwa kayan aikin hannu waɗanda basa buƙatar bayyanuwa da aiki.

Tabarau mai haske tare da buga silkscreen

Madalla da bugawar allo mai yawa

Kushin bugawa akan farfajiya

Biyu launi & Multi launi kushin bugu

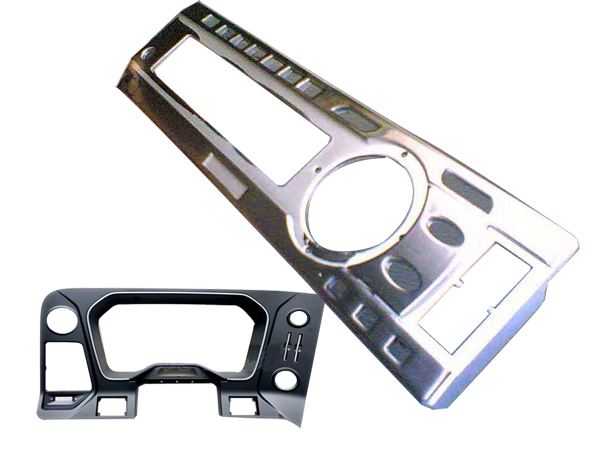

Sassan filastik tare da sanya wutar lantarki

Sassan filastik tare da kwalliyar kwalliya

5. Zafin zafi

Ana kuma kiran zafin zinare tagulla ko zinare.

Tsarin bugawa da ado. Farantin karfe ya yi zafi, an buga zinariya, kuma an buga alamun zinariya ko alamu a kan abin da aka buga. Tare da ci gaba da sauri na zafin zafin zinariya da masana'antun masana'antu, aikace-aikacen zafin lantarki na lantarki yana da ƙari sosai.

A cikin aikin buga kayayyakin samfuran filastik, hatimi mai zafi da buga siliki suna da sauƙin aiki da yaduwar dab'i da yadu. Suna da halaye na ƙananan tsada, aiki mai sauƙi, ba sauƙin faɗuwa ba, kyakkyawa da karimci, da wadataccen aiki. Zasu iya buga sunayen kamfanoni daban-daban, LOGO, farfaganda, tambari, lambobi da sauransu.

Ka'idoji da halaye na fasahar zinare zinariya:

Tsarin zafin zafi yana amfani da ƙa'idar sauya matsin lamba mai zafi don canza layin aluminum a cikin aluminum na lantarki zuwa farfajiyar substrate don samar da tasirin ƙarfe na musamman. Saboda babban abin da ake amfani dashi a cikin zafin zafin shine takardar aluminiy na lantarki, aikin zafin zafin ana kuma kiransa zafin lantarki na lantarki. Electrolytic aluminum tsare yawanci hada da Multi-Layer kayan, tushe abu ne yawanci PE, bi da rabuwa shafi, launi shafi, karfe shafi (aluminum plating) da kuma manne shafi.

(1) Adon saman zai iya kara darajar kayayyakin. Haɗe tare da wasu hanyoyin sarrafawa kamar ƙwanƙwasa ƙwanƙwasa da latsa kumburi, yana iya nuna ƙarfin tasirin ado na samfurin.

(2) Don bawa samfuran mafi girman aikin hana jabu, kamar su sanya hoton holographic, hatimi mai zafi, alamar kasuwanci, da dai sauransu Bayan samfurin ya zama tagulla, alamu sun bayyana, kyawawa, launuka, masu iya sanyawa da kuma yanayin yanayi. A halin yanzu, aikin fasahar kere-kere a kan tambarin taba sigari ya kai sama da 85%. A cikin zane-zane, tagulla na iya taka muhimmiyar rawa wajen haskaka jigon zane, musamman don ƙawancen amfani da alamun kasuwanci da sunayen rijista.

Murfin filastik tare da alamar zafi mai zafi

Hannun zafi a saman filastik don kariya

6.Lasser zane

Ana kuma kiran zane-zanen Laser sassaƙa radium ko alamar laser. Fasaha ce mai maganin farfajiya bisa dogaro da ƙirar gani. Har ila yau, zane-zanen Laser shima aikin magani ne na farfajiya, kwatankwacin buga allo, ana buga shi akan samfuran ko sifofi, kuma tsarin ya bambanta, farashin ya bambanta. Ka'idar aikin sarrafa laser.

(1) Ana amfani da katakon laser mai ƙarfi mai ƙarfi wanda laser ke fitarwa don sanya kayan abu da sarrafa shi.

(2) Tasirin sa alama shine fallasa abubuwa masu zurfin ta hanyar ƙazantar abubuwa masu lahani, ko haifar da alamun sinadarai da canje-canje na zahiri na abubuwan da ke saman su da ƙarfin haske, ko ƙona wasu abubuwa ta hanyar makamashin haske, da alamun "zana", ko kona wasu abubuwa ta hanyar kuzari, don nuna zane da kalmomin da ake buƙata

(3). Harka

Misali, ina son yin makulli, wanda yake dauke da kalmomi a kai, kamar shudi, kore, makullin ja, sannan in fesa dukkan abin hawa. Fari, wannan cikakken farin maballin ne, kuma dukkan shudi da launin kore suna da launin toka, jikin mabuɗin fari ne, zane-zanen laser, man fesa na farko, shuɗi, kore, ja, launin toka, kowane feshi daidai launi, ka mai da hankali ba fesa kan wasu maɓallan, don ya zama kamar akwai makullin shuɗi, maɓallan kore da sauran waɗanda aka nade a ƙarƙashinsa. A wannan lokacin, za a iya aiwatar da sassar laser, ta amfani da fasahar laser da maɓallan maɓallin ID ɗin da aka yi da fim, wanda aka sassaka babban farin mai, kamar harafin sarrafawa "A", an sassaka farin shanyewar jiki, sannan na gaba ko shuɗi ko kore za a fallasa, don haka ƙirƙirar makullin harafin launuka iri-iri.

A lokaci guda, idan kanaso ka zama mai haske, kayi amfani da PC ko PMMA, ka fesa mai mai, ka sassaka sashin rubutun, to hasken da ke ƙasa zai fito, amma a wannan lokacin ka yi la’akari da mannewar mai daban-daban, yi ba fesa a kan karce kashe

Maballin keɓaɓɓen maɓalli na katako don faifan maɓalli

Tsarin Laser wanda aka zana akan shari'ar kariya

Batun filastik tare da alamun kwalliyar laser

Tsarin Laser wanda aka zana akan filastik mai haske

Mestech ba kawai ta samarwa kwastomomi kayan kwalliya da samar da allura ba, amma kuma tana samarwa da kwastomomi ayyukan daki-daki guda daya kamar su fenti, zaban lantarki, da sauransu Idan kayan ka suna da irin wannan bukatar, sai a tuntube mu.