Sarrafa karfe (aikin karafa), wani nau'in fasaha ne na sarrafa abubuwa da ayyukan samar da kayayyaki, bangarori da kayan aikin daga kayan karafa.

Ana amfani da sassan ƙarfe a cikin injuna da kayan aiki daban-daban. Partsananan sassa suna da kwanciyar hankali na girma, ƙarfi da tauri, halaye masu ƙarfi da ƙananan yanayin juriya da haɓaka, waɗanda galibi ana amfani dasu don yin sassan daidaito. Idan aka kwatanta da sassan filastik, akwai nau'ikan kayan abubuwa da yawa na sassan karafa, kamar su alloy alloy, alloy steel, zinc alloy, steel, titanium alloy, magnesium alloy, da dai sauransu, tare da kaddarori daban-daban. Daga cikin su, ana amfani da ferroalloy, aluminum alloy, copper alloy da zinc alloy a masana'antar da kayayyakin fararen hula. Wadannan kayan karafa suna da nau'ikan kayan jiki da na sinadarai daban-daban, tsari daban-daban da sifar kayan sarrafa sassan karfe yana da babban bambanci.

Babban hanyoyin sarrafa kayan karafan sune: gyaran inji, buga tambari, gyaran simintin gyare-gyare, aikin karafan foda, gyaran allurar karfe.

Machining shine aiwatar da sauya gabaɗaya girma ko aikin abin aiki ta hanyar nau'in kayan aikin inji. Dangane da bambanci cikin hanyoyin sarrafawa, ana iya raba shi zuwa yankan inji da matsin lamba. Stamping wani nau'in tsari ne na yin tsari wanda yake amfani da latsawa kuma ya mutu don yin amfani da karfi na waje akan takarda, tsiri, bututu da bayanin martaba don samar da nakasar filastik ko rabuwa, don samun sifar da ake buƙata da girman girman aikin (ɓangaren sintiri).

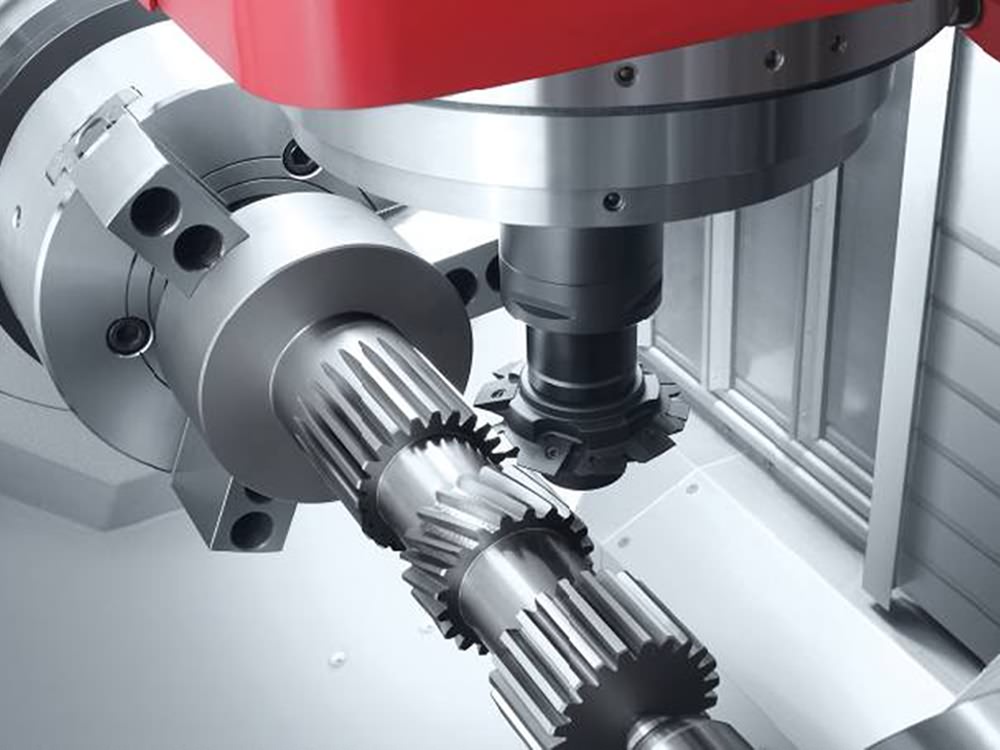

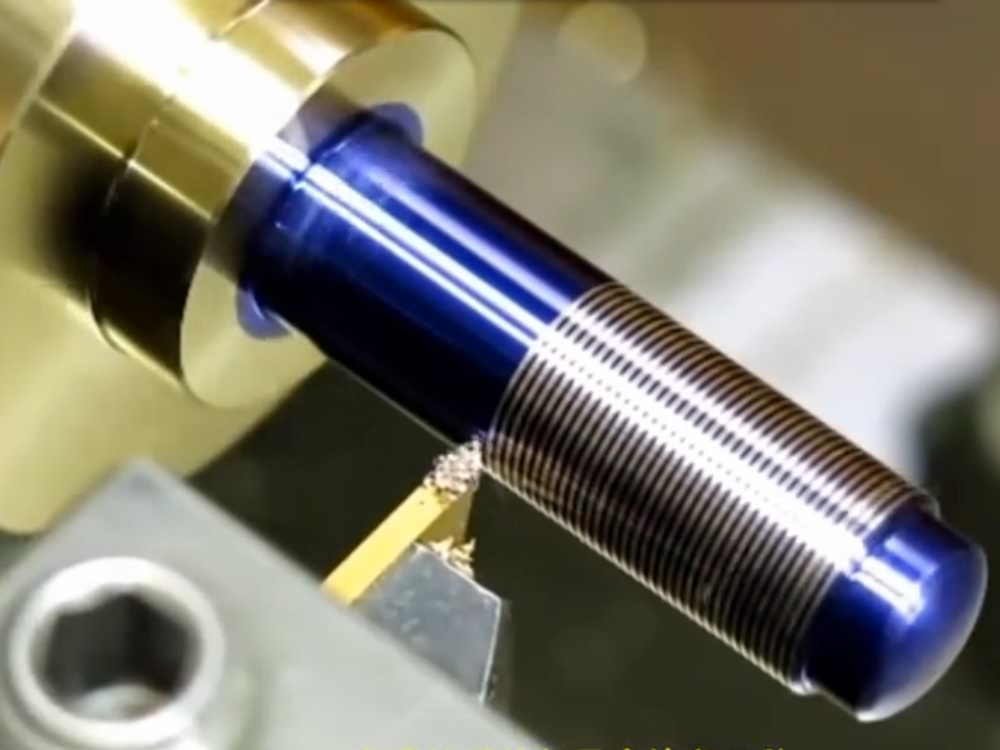

Daidaici simintin gyaran kafa, foda metallurgy da karfe allura gyare-gyaren kasance daga zafi aiki tsari. An ƙirƙira su a cikin ramin ƙirar ta hanyar dumama narkakken ƙarfe a zazzabi mai ƙarfi don samun sifa da girman da ake buƙata. Hakanan akwai keɓaɓɓiyar ƙira, kamar: kera laser, EDM, ultrasonic machining, electrochemical machining, barbashi katako machining da ultra-high speed machining. Juyawa, niƙa, ƙirƙira, da simintin gyare-gyare, niƙa, injunan CNC, ƙirar CNC. Dukansu na aikin inji ne.

Kayan aikin inji don sarrafa karafa

Kayan aikin inji don sarrafa karafa

Shaft machining - Cibiyar lathe

Kayan aikin lantarki -EDM

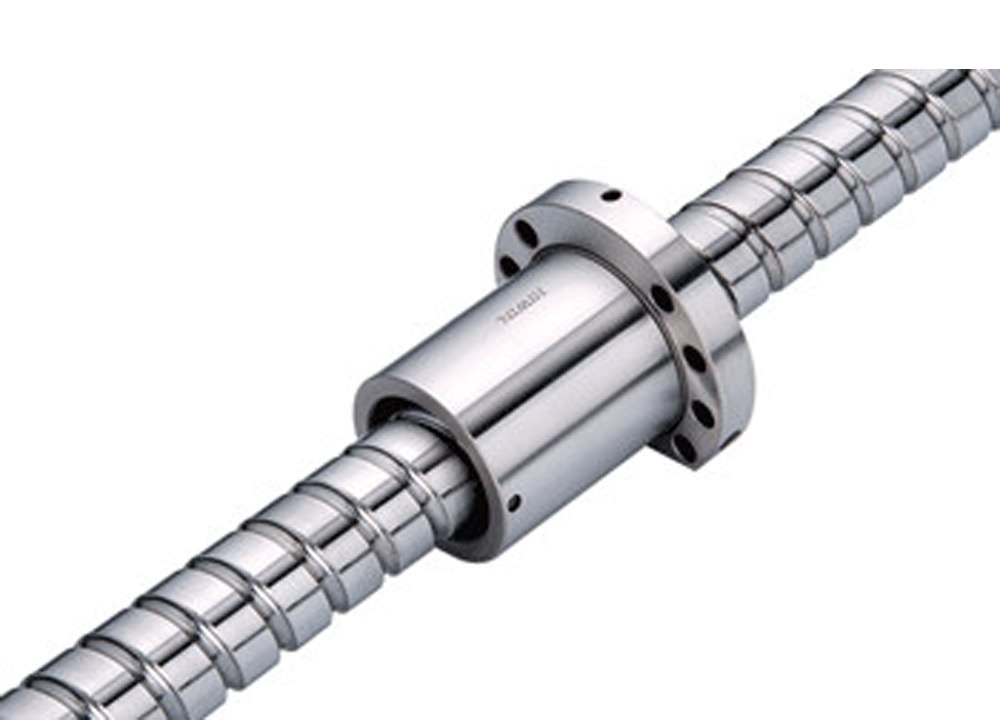

Daidaici dunƙule machining

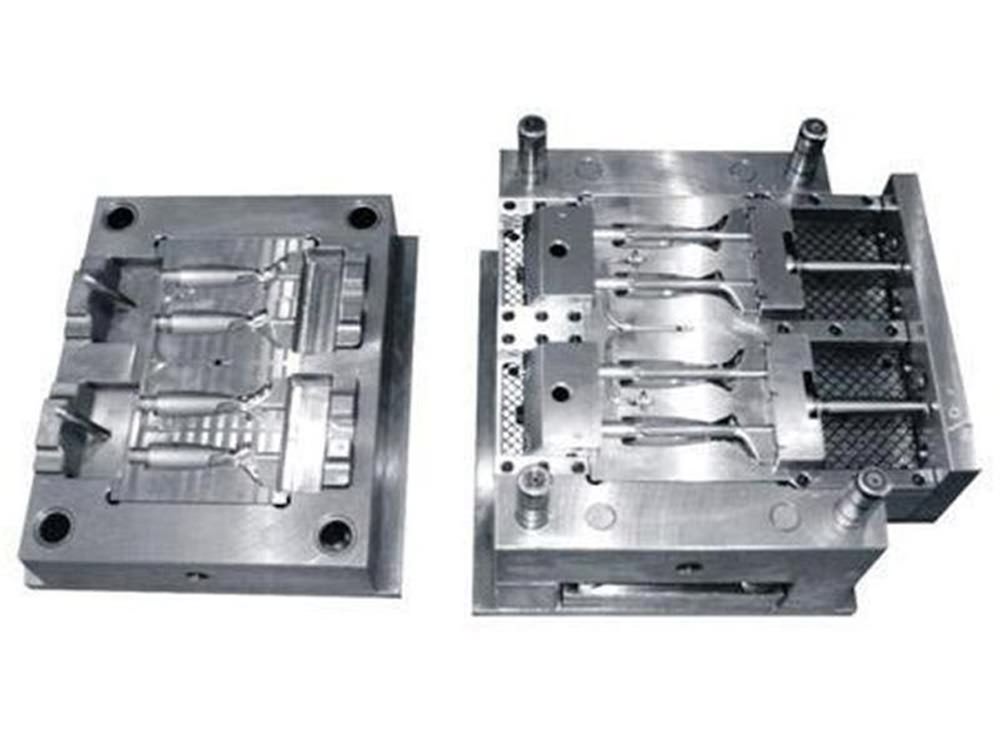

Mutu 'yan wasa inji

Mutu 'yan wasa mutu

Injin Punching

Stamp ya mutu

Nunin sassan karfe:

1. metalananan ƙarfe masu ƙarfe: sassan da aka yi da baƙin ƙarfe, da chromium, da manganese da kayan haɗarsu.

Daidaici mold sassa

CNC sassa karfe

Daidaici gubar dunƙule

Sassan watsa gear

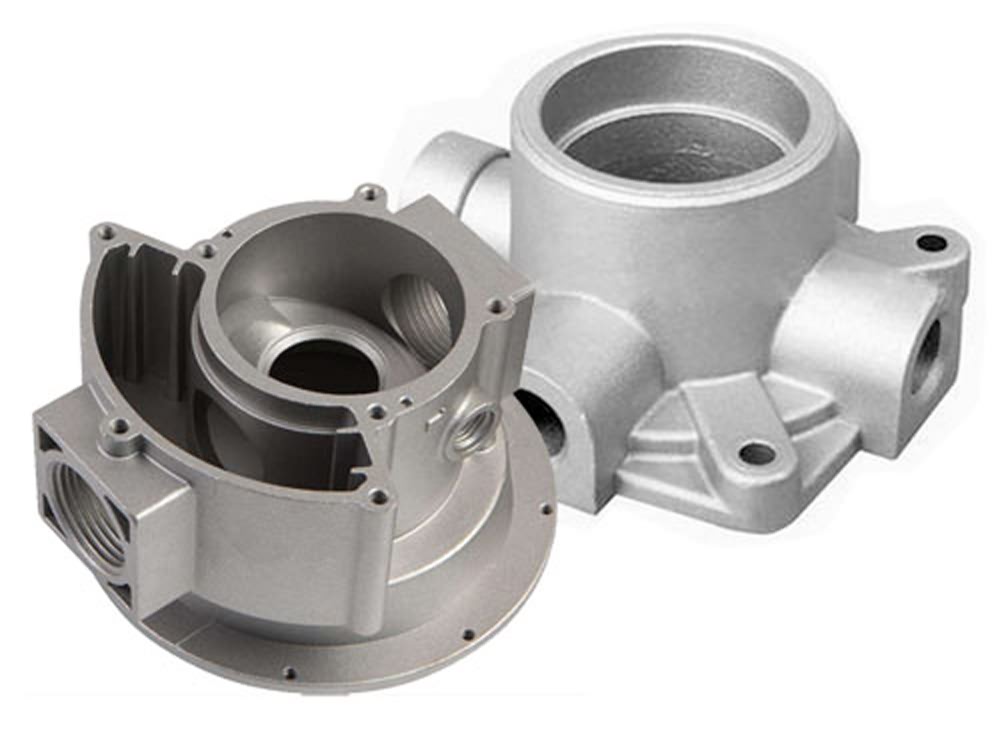

2. Abubuwan da ba su da karafa: kayan aikin da ba a amfani da su ba sun hada da sinadarin aluminium, tagulla, magnesium alloy, nickel alloy, tin alloy, tantalum alloy, titanium alloy, zinc alloy, molybdenum alloy, zirconium alloy, da sauransu

Tagulla

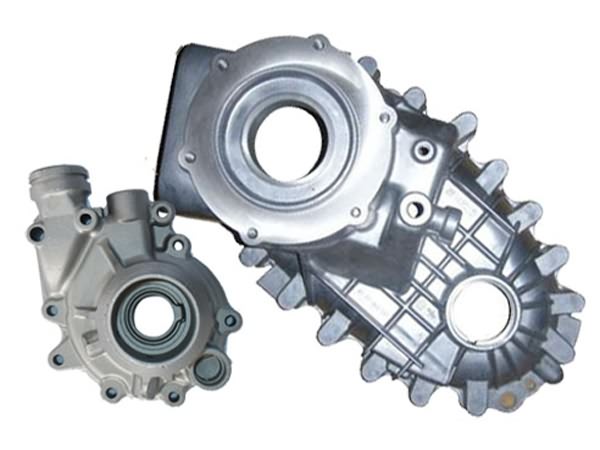

Zinc ya mutu gidan jefa gidaje

Aluminum stamping murfin

Aluminum mutu 'yar simintin gidaje

Za'a iya raba maganin farfajiyar zuwa gida hudu

1. Mechanical surface treatment: sandblasting, harbi ayukan iska mai ƙarfi, gogewa, mirgina, gogewa, goge gogewa, fesawa, zane, mai, da dai sauransu.

2. Chemical farfajiyar jiyya: bluing da blackening, phosphating, pickling, electroless plating na daban-daban karafa da gami, TD magani, QPQ magani, sunadarai hadawan abu da iskar shaka, da dai sauransu

3. Electrochemical surface jiyya: anodic hadawan abu da iskar shaka, electrochemical polishing, electroplating, da dai sauransu

4. Maganin farfajiya na zamani: CVD tururin ɗora sinadarai, PVD tururin jiki, ion dasawa, saka ion, maganin farfajiyar laser, da sauransu.

Mestech tana bawa kwastomomi ƙira da sabis na masana'antu don ɓangarorin ƙarfe da suka haɗa da ƙarfe, gami na aluminium, zinc, ƙarfe na jan ƙarfe da sinadarin titanium. Da fatan za a tuntube mu idan ya cancanta.