Yadda ake tsara sassan roba

Short Bayani:

Zuwa tsara sassan filastikshine don ayyana fasali, girma da daidaito na sassan, gwargwadon rawar da sassan ke takawa a cikin samfurin, da ƙa'idar tsarin gyare-gyare don filastik. Sakamakon ƙarshe shine zane don ƙera kayan aiki da ɓangaren filastik.

Kayan masana'antu yana farawa tare da zane. Tsarin ɓangarorin filastik kai tsaye yana ƙayyade fahimtar tsarin ciki, farashi da aikin samfurin, sannan kuma yana ƙayyade mataki na gaba na samar da ƙira, farashi da sake zagayowar, da ƙirar allura da aiwatar da aikin bayan fage da farashi.

Ana amfani da sassan filastik a cikin samfuran daban-daban, wurare da rayuwar mutane a cikin rayuwar zamani. Sassan filastik suna buƙatar siffofi da ayyuka daban-daban. Suna amfani da kayan roba kuma kadarorinsu sun banbanta. A lokaci guda, akwai hanyoyi da yawa don yin sassan filastik a cikin masana'antu. Don haka don tsara sassan filastik ba aiki bane mai sauki.

Daban-daban bangare zane da kuma kayan da aka samar daban-daban aiki. Aikin sarrafa filastik ya kunshi kasa:

1. shigar da allura

2.blowing gyare-gyare

3.comyin rubutu

4. gyaran kafa

5. gyarawa

6.matsuwa

7.fabrication

8.fama

Akwai hanyoyi da yawa don samar da su da yawa. Allurar gyare-gyare sanannen hanyar masana'antu ne, saboda allurar da aka ƙera 50% ~ 60% sassan filastik ana samar da su ta hanyar allurar gyare-gyaren allura, ƙarfin aiki ne mai sauri.

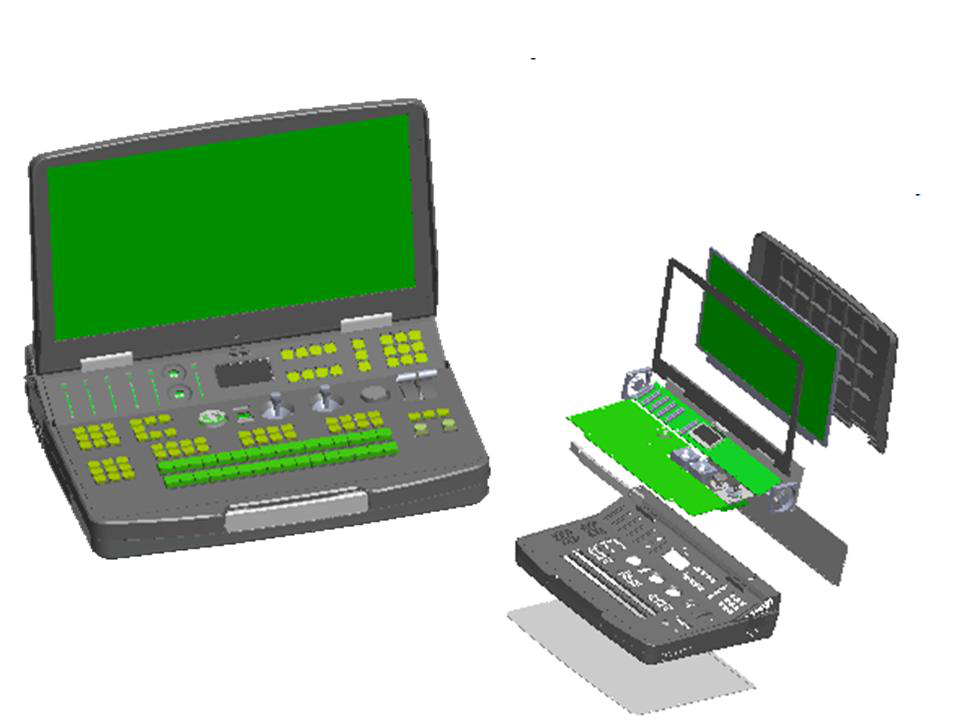

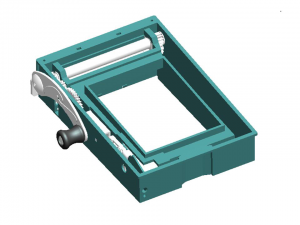

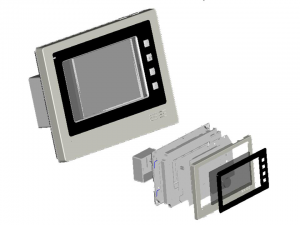

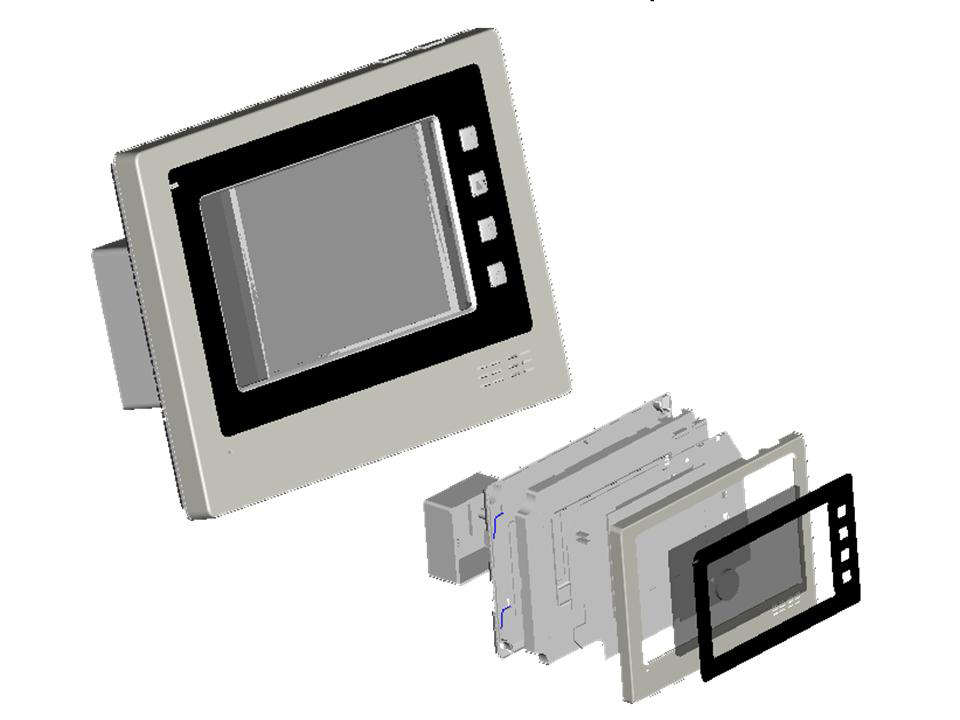

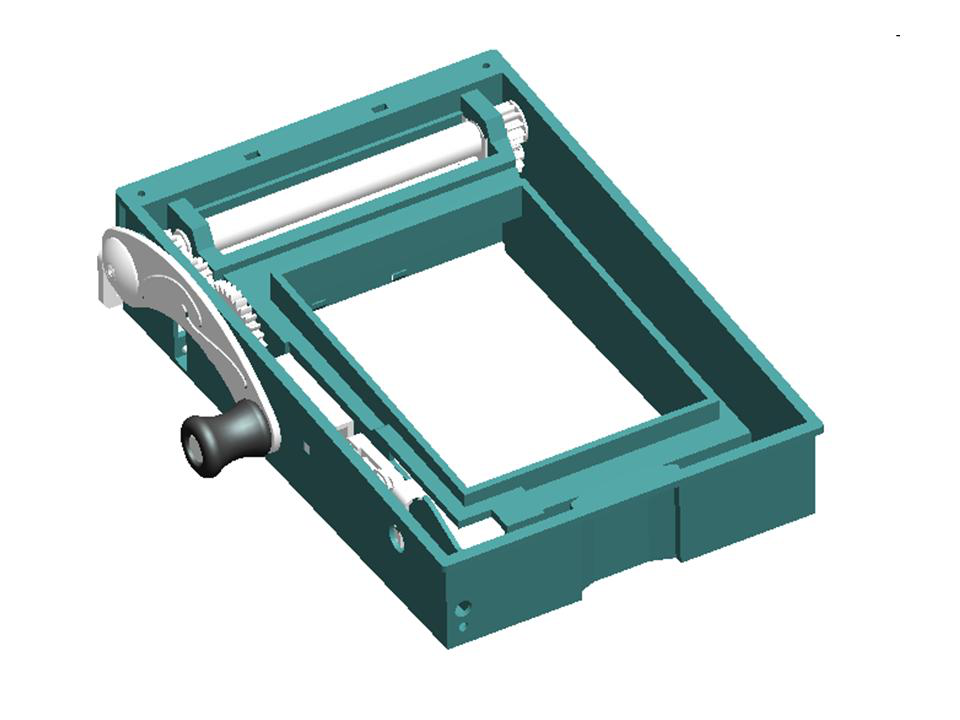

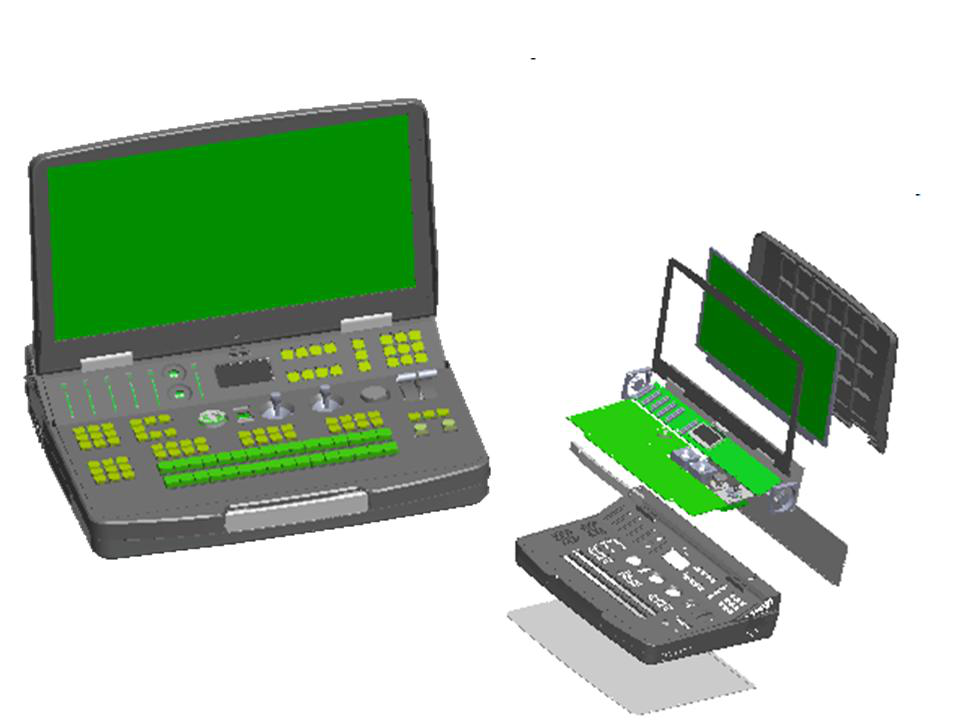

Nuna akwati don wasu sassan filastik da muka tsara:

Filastik yadi na wayar gani

Filastik sassan inji

Filastik lokuta na lantarki

Gidajen filastik don kayan aiki

A ƙasa muna raba dalla-dalla yadda za a tsara sassan filastik a cikin fannoni uku

* Nasihu 10 don ƙirar sassan filastik dole ne ku sani

1.Yayyade tsarin bayyanar da girman samfurin.

Wannan shine mataki na farko a cikin dukkan tsarin ƙira. Dangane da bincike na kasuwa da bukatun abokin ciniki, ƙayyade bayyanar da aikin samfuran, da tsara ayyukan ci gaban samfur.

Dangane da aikin ci gaba, ƙungiyar ci gaba tana aiwatar da bincike kan ƙwarewar fasaha da fasaha ga samfurin, kuma suna ƙirar samfurin 3D na samfurin. Bayan haka, gwargwadon fahimtar aiki da haɗuwa da samfur, ana shirya sassan da za'a iya yi.

2.Yawaita sassan mutum daga zane-zanen samfura, zabi nau'in guduro na filastik don sassan filastik

Wannan matakin shine don raba sassan daga samfurin 3D da aka samo a cikin matakin da ya gabata kuma tsara su azaman mutum. Dangane da bukatun aiki na sassan, zaɓi kyawawan kayan roba ko kayan masarufi. Misali, ana amfani da ABS a cikin

harsashi, ABS / BC ko PC ana buƙatar samun wasu kayan aikin inji, sassa masu haske kamar fitila, fitilar fitilar PMMA ko PC, kaya ko sa sassan POM ko Nylon.

Bayan zaɓar kayan kayan sassan, za'a iya fara ƙirar dalla-dalla.

3.Define daftarin kusurwa

Kusassun kusurwa sun ba da izinin cire filastik daga sifa. Ba tare da matakan kusurwa ba, sashin zai bayar da babban juriya saboda gogayya yayin cirewa. Yakamatattun kusassun kusurwa su kasance a ciki da bayan ɓangaren. Mafi zurfin sashi, ya fi girma daftarin kusurwa. Simplea'idar yatsa mai sauƙi ita ce a sami kusurwa kusurwa 1 ta kowace inch. Rashin samun isasshen kusurwa na iya haifar da ɓarna a gefen ɓangarorin da / ko manyan alamomin ejector (ƙari akan wannan daga baya).

Tsararrun kusurwa na farfajiyar waje: Mafi zurfin sashi, ya fi girma daftarin kwana. Simplea'idar yatsa mai sauƙi ita ce a sami kusurwa kusurwa 1 ta kowace inch. Rashin samun isasshen kusurwa na iya haifar da ɓarna a gefen ɓangarorin da / ko manyan alamomin ejector (ƙari akan wannan daga baya).

Yawancin lokaci, don samun kyakkyawan yanayin gani, ana yin zane a saman sassan. Bangon da zane yake da laushi, gogayya babba ce, kuma ba sauki a cire ta daga cikin ramin ba, don haka tana buƙatar kusurwa mafi girma. Textureaƙƙarwar da ba ta da kyau ita ce, mafi girman buƙatar da ake buƙata.

4.Define kaurin bango / kauri iri ɗaya

M siffar gyare-gyaren ba a so a allura gyare-gyaren saboda wadannan dalilai:

1) .Cooling lokaci ne na gwargwado ga square na bango kauri. Lokaci mai sanyaya don tsayayye zai kayar da tattalin arziƙin ƙasa. (matalauta mai gudanar da zafi)

2) .Thicker sashe yana ƙyamar fiye da ɓangaren sirara, don haka gabatar da ƙyamar banbanci wanda ke haifar da shafuka ko alamar nutsewa da sauransu (halayen ƙyama na robobi da halaye na pvT)

Saboda haka muna da doka ta asali don ƙirar ɓangaren filastik; gwargwadon yiwuwar kaurin bango ya zama ya zama mai daidaituwa ko tsayayye ta cikin ɓangaren. Wannan kaurin bangon ana kiran sa da kaurin bango maras muhimmanci.

Idan akwai wani sashe mai ƙarfi a cikin ɓangaren, ya kamata a zama rami ta hanyar gabatar da ginshiƙi. Wannan ya tabbatar da kaurin bangon bai-daya a kewayen cibiyar.

3). Menene abubuwan la'akari don yanke shawarar kaurin bango?

Dole ne ya zama mai kauri da isa ga aikin. Kaurin bango na iya zama 0.5 zuwa 5mm.

Hakanan dole ne ya zama sirara don isa cikin sauri, wanda zai haifar da ƙarancin ɓangare da haɓaka mai girma.

Duk wani bambanci a cikin kaurin bango ya kamata a kiyaye shi a matsayin mafi ƙarancin yiwu.

Wani ɓangaren filastik tare da kaurin bango daban-daban zai sami ƙimar banbancin sanyaya da ƙyama daban. A irin wannan hali samun haƙuri na kusa yana da matukar wahala kuma sau da yawa ba zai yuwu ba. Inda bambancin kaurin bango yake da mahimmanci, miƙa mulki tsakanin su ya zama sannu-sannu.

5.Connection design tsakanin sassan

Yawancin lokaci muna buƙatar haɗa bawo biyu tare. Don ƙirƙirar daki kewaye tsakanin su don sanya abubuwan da ke ciki (taron PCB ko inji).

Nau'in haɗin haɗin yau da kullun:

1). Snapara ƙugiya:

Ana amfani da haɗin haɗin ƙwanƙwasa ƙirar ƙanana da matsakaita. Halinsa shine cewa ƙugiyoyin ƙugiya gabaɗaya an saita su a gefen sassan, kuma ana iya ƙara girman samfurin. Lokacin da aka haɗu, ana rufe shi kai tsaye ba tare da amfani da kowane irin kayan aiki ba kamar su sikila, walda na ultrasonic ya mutu da sauransu. Rashin hasara shine cewa ƙwanƙwasa ƙwanƙwasawa na iya haifar da rikitarwa mafi rikitarwa. Ana buƙatar inji mai silar darjewa da kayan ɗagawa don fahimtar haɗuwa da ƙuƙwalwar karu da ƙara farashin mai ƙira.

2). Dunƙule gidajen abinci:

Dunƙule gidajen abinci tabbatacce ne kuma abin dogara. Musamman ma, gyaran dunƙulen + goron yana da matukar aminci kuma mai ɗorewa, yana ba da damar taruwa da yawa ba tare da fasa ba. Haɗin haɗin dunƙule ya dace da samfuran tare da babban ƙarfin kullewa da rarrabawa da yawa. Rashin hasara shine sashin dunƙulen yana ɗaukar ƙarin sarari.

3). Hawa shugabannin:

Haɗin haɗin shugabanni shine gyara sassa biyu ta hanyar daidaitaccen daidaituwa tsakanin shugabannin da ramuka. Wannan hanyar haɗin ba ta da ƙarfi don ba da damar rarraba samfuran. Rashin dacewar shine ƙarfin kullewa zai ragu yayin da lokacin tarwatsewa ke ƙaruwa.

4). Ultrasonic waldi:

Welding Ultrasonic shine ta sanya sassa biyu a cikin ultrasonic mold da fusing lamba surface karkashin aikin ultrasonic waldi inji. Girman samfurin na iya zama karami, ƙwayar allurar ba ta da sauƙi, kuma haɗin haɗin yana da ƙarfi. Rashin amfani shine amfani da ultrasonic mold da ultrasonic waldi machine, samfurin ba zai iya zama babba ba. Bayan rarrabawa, ba za a sake amfani da sassan ultrasonic ba.

6.Yawan Jiki

Maɓallin motsa jiki abubuwa ne da ke tsoma baki tare da cire ko wanne rabin kayan aikin. Maɓallin cirewa na iya bayyana kusan a ko'ina a cikin ƙirar. Waɗannan ba su da karɓa, in ba mafi munin rashin rashin kusurwa a ɓangaren ba. Koyaya, wasu ƙananan hanyoyi suna da mahimmanci kuma / ko ba makawa. A waɗancan lokuta, ya zama dole

ana samar da ƙananan abubuwa ta ɓangaren zamiya / motsi a cikin sifar.

Ka tuna cewa ƙirƙirar ƙananan abubuwa sun fi tsada yayin samar da ƙirar kuma ya kamata a kiyaye su zuwa mafi ƙarancin abu.

7. Tallafa haƙarƙari / Gussets

Ribs a cikin ɓangaren filastik suna haɓaka ƙarfi (dangantaka tsakanin ɗorawa da ɓatar da ɓangare) na ɓangaren kuma yana ƙara ƙarfi. Hakanan yana haɓaka ƙwanƙwasa-ƙarfi yayin da suke hanzarin narkewar gudana a cikin ɓangaren haƙarƙarin.

Ana sanya haƙarƙari tare da jagorancin matsakaicin damuwa da karkatarwa a saman samfuran ɓangaren. Fillingarin cika, raguwa da fitarwa ya kamata suma suyi tasiri game da yanke shawara game da sanya hakarkarinsu.

Hakarkarin da ba su haɗu da bango a tsaye ba zai ƙare ba zato ba tsammani. Canji a hankali zuwa bango mara suna ya kamata ya rage haɗarin matattarar damuwa.

Rib - girma

Hakarkarin ya kamata su kasance suna da girma.

Yawan kaurin ya kamata ya kasance tsakanin 0.5 zuwa 0.6 sau kaurin bangon bango don kaucewa alamar nutsarwa.

Hakarkarin haƙarƙari ya zama sau 2.5 zuwa sau 3 kaurin bango maras muhimmanci.

Rib ya kamata ya sami 0.5 zuwa digiri na digiri na 1.5 don sauƙaƙe fitarwa.

Baseaƙarin Rib yana da radius 0.25 zuwa 0.4 sau kaurin bangon mara suna.

Nisa tsakanin haƙarƙari biyu ya zama sau 2 zuwa 3 (ko sama da haka) kaurin bangon mara suna.

8.Yankan Rage

Lokacin da fuskoki biyu suka hadu, yana yin kusurwa. A kusurwa, kaurin bango yana ƙaruwa zuwa sau 1.4 bangon bango mara ban sha'awa. Wannan yana haifar da raguwa daban-daban da kuma cikin damuwa da kuma lokacin sanyaya mai tsayi. Sabili da haka, haɗarin gazawa a cikin sabis yana ƙaruwa a kusurwa masu kaifi.

Don magance wannan matsalar, yakamata a daidaita sasanninta tare da radius. Ya kamata a samar da radius a waje da kuma cikin gida. Kada ka sami kusurwa ta ciki kamar yadda take inganta tsaga. Radius ya zama irin wannan don suna tabbatar da dokar ƙawancen bango mai ɗorewa. Zai fi dacewa a sami radius na 0.6 zuwa sau 0.75 kaurin bango a kusurwa. Kada ka sami kusurwa ta ciki kamar yadda take inganta tsaga.

9.Screw shugaba zane

Kullum muna amfani da sukurori don gyara lamura biyu tare, ko ɗaura PCBA ko wasu abubuwan haɗin akan sassan filastik. Don haka shuwagabannin shuke-shuke tsari ne na dunƙulewa zuwa tsayayyun sassa.

Dunƙulen maigidan yana da siffar siliki. Ana iya haɗa maigidan a tushe tare da ɓangaren mahaifiya ko kuma ana iya haɗa shi a gefe. Haɗawa a gefe na iya haifar da ɓangaren ɓangaren filastik, wanda ba kyawawa bane saboda yana iya haifar da alamar nutsar ruwa da haɓaka lokacin sanyaya. Ana iya magance wannan matsalar ta hanyar haɗa maigida ta haƙarƙarin ga bangon gefe kamar yadda aka nuna a jikin zane. Za'a iya yin shugaban da ƙarfi ta hanyar samar da haƙarƙarin haƙarƙari.

Ana amfani da dunƙule a kan maigidan don ɗaure wani ɓangaren. Akwai nau'ikan dunƙulen igiya da ƙwanƙwaran shinge. Ana amfani da dunƙulen kafa zaren a kan thermoplastics kuma ana amfani da sukurorin yanke zaren akan sassan filastik na thermoset.

Readinƙirar zaren da ke samar da zaren mata a bangon maigidan ta hanyar ruwan sanyi - filastik yana da nakasa a cikin gida maimakon yankewa.

Wajan dunƙule dole ne ya daidaita girma don tsayayya da ƙarfin shigar da dunƙule da lodin da aka ɗora akan dunƙule cikin sabis.

Girman dandalar da aka haifa da dunƙulen yana da mahimmanci don juriya da zaren zane da dunƙule da aka ciro.

Yakamata diamita na waje ya zama mai girma don tsayayya da matsalolin hoop saboda zaren da yake yi.

Bore yana da ɗan ƙaramin faɗi kaɗan a lokacin shiga don gajeren tsayi. Wannan yana taimakawa wurin gano dunƙule kafin tuki a ciki. Hakanan yana rage damuwa a ƙarshen ƙarshen maigidan.

Polymer masana'antun suna ba da jagororin ƙayyade girman maigidan ga kayan aikin su. Hakanan masana'antun dunƙule suna ba da jagorori don girman girman huda don dunƙule.

Ya kamata a kula sosai don tabbatar da haɗin haɗin walda mai ƙarfi a cikin dunƙulewar maɓallin cikin maigidan.

Ya kamata a kula don kauce wa yanayin damuwa cikin maigida saboda zai iya cin nasara a ƙarƙashin mawuyacin hali.

Korawa a cikin shugaba ya kamata ya fi zurfin zaren nesa.

10.Fuskar ado

Wani lokaci, don samun kyaun gani, muna yin magani na musamman akan farfajiyar filastik.

Kamar su: zane, mai sheƙi mai haske, zanen feshi, zane-zanen laser, zafin zafin rana, zaɓin lantarki da sauransu. Wajibi ne a yi la'akari da ƙirar samfurin a gaba, don kauce wa aiki na gaba ba za a iya cimma ko canje-canje masu girma da suka shafi haɗuwar samfur ba.