Gilashin allurar filastik shine wanda akafi amfani dashi daya daga cikin gyaran filastik. Ana amfani da sassan roba da aka gyara su a kayan lantarki, lantarki, lantarki, likitanci, sufuri, mota, haske, kare muhalli, tsaro, kayan aikin gida, kayan wasanni da sauran masana'antu da samfuran.

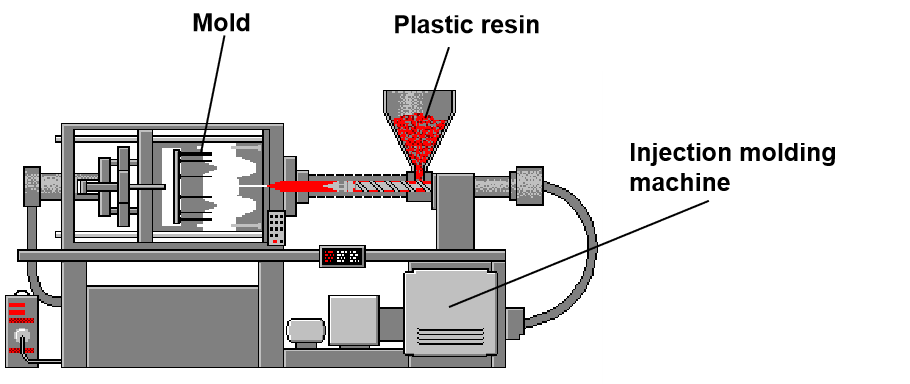

Menene ingancin allura? Gwanin allurar filastik tsari ne na masana'antu don samar da sassa a cikin wani kewayon yanayin zafin jiki, ta hanyar dunƙulewa yana narkar da kayan aikin filastik da aka narkar da su, allurar matsin lamba a cikin ramin ƙirar, bayan sanyaya da warkarwa, don samun hanyar gyaran. Wannan hanyar ta dace da samar da tsari na hadaddun sassa kuma yana daya daga cikin mahimman hanyoyin sarrafawa. Akwai matakai guda 6: rufe ƙira, narkewar allurar filastik, riƙe matsin lamba, sanyaya, buɗe buɗaɗen samfura da fitar da samfur. Sauri, matsin lamba, matsayi (bugun jini), lokaci da kuma yawan zafin jiki sune mahimman abubuwa guda 5 na gyaran allura.

Abubuwa uku na ƙungiyar samar da allura

Aikace-aikacen kayan kwalliyar allura

(1) a cikin kayayyakin lantarki: .Kaɗa kayayyakin sadarwa da kayayyakin lantarki da mabukata (gidaje masu filastik, yadi, akwati, murfi) Wayoyin hannu, belun kunne, talabijin, wayoyin bidiyo, injunan POS, ƙarar ƙofar.

(2) a cikin kayan cikin gida: Mai yin kofi, juicer, firiji, kwandishan, mai wankin fan da tanda

(3) a cikin kayan lantarki: Mita na lantarki, akwatin lantarki, kujerun lantarki, mai sauya mita, murfin rufi da sauyawa

(4) a cikin kayan aikin likitanci da kiwon lafiya da na'urori: fitilun aiki, sphygmomanometer, sirinji, dropper, kwalban magani, tausa, na'urar cire gashi, kayan motsa jiki

(5) a cikin mota: Tsarin jikin dashboard, sashin baturi, ɓangaren gaban, akwatin sarrafawa, akwatin tallafi na wurin zama, wurin haifuwa na mahaifa, fender, damina, murfin katako, katangar amo, ƙofar baya.

(6) A cikin kayan aikin masana'antu: Kwamitin kayan aikin injiniya, kaya, sauyawa, haske.

(7) Na'urar zirga-zirga da kayan abin hawa (murfin fitila, yadi) Fitilar sigina, sigina, mai gwajin barasa.

Abubuwa uku na ƙungiyar samar da allura

Mould, allurar gyare-gyaren inji da kuma roba albarkatun kasa ne na asali naúrar da allura gyare-gyaren. Kayan kwalliya da inginin gyare-gyare sune kayan aikin samarwa, kuma ana amfani da albarkatun roba don samar da kayan samfur.

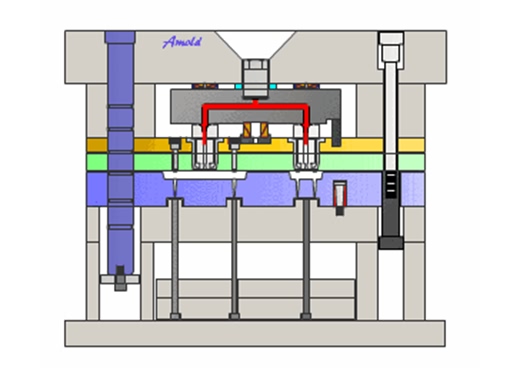

1. kyawon allura

Injection mold wani nau'in kayan aiki ne don samar da kayayyakin roba; Hakanan kayan aiki ne don ba samfuran filastik cikakken tsari da madaidaitan girma. Allurar gyare-gyaren wata nau'in hanyar sarrafawa ce wacce ake amfani da ita wajen samar da wasu sassa masu rikitarwa. Musamman, ana sanya narkewar filastik cikin ramin ƙirar ta injin inji mai ingin a ƙarƙashin matsin lamba, kuma ana samun samfurin da aka ƙera bayan sanyaya da warkewa. Injection mold za a iya raba shi zuwa nau'ikan daban-daban bisa tsari daban-daban, bukatun ƙirar samfur, yanayin samarwa da shigarwa da yanayin amfani.

Saboda tsadar masana'antun kayan kwalliya, amma tsawon rayuwar su da ingancin aikin su, galibi ana amfani dasu ne don samar da taro. Alurar allura ana amfani dashi don samar da sassan roba. Adadi mai yawa na samfuran filastik masu inganci, suna rarraba farashin ƙirar ƙira, don haka farashin masana'antun kayan ƙirar allura ɗaya ya fi na sauran hanyoyin sarrafawa nesa ba kusa ba. Akwai matakai uku na ƙirar ƙira da ingancin sifa.

(1) Mould zane:

Mould zane dogara ne akan samfurin zane, da yin amfani da zane software, bisa ga mold masana'antu matakin na inji aiki da allura gyare-gyaren aiwatar halaye, zane na dukan mold tsari, sassa.

(a) Mataki na farko shine yin nazarin ƙirar kayayyakin roba

(b) Mataki na biyu shine zaɓi na kayan mutu

(c) Mataki na uku shine ƙirar ƙirar ƙira

(d) Mataki na huɗu shine ƙirar sassan mould

(2) Molding aiki

Mould aiki ne yafi ta hanyar inji aiki don kammala Zane review, kayan shiri, aiki, mold tushe aiki, mold core aiki, lantarki aiki, mold sassa aiki, dubawa, taro, yawo mold, gwaji mold

A aiki sake zagayowar na allura mold ya dogara da wuya da aiki matakin na mold. Gabaɗaya tsarin sake zagayowar shine kwanakin aiki 20-60. Injin da ake amfani da shi wajen sarrafa kayan kwalliya: CNC, lathe, injin niƙa na gari, injin niƙa, EDM, WEDM, haɗuwa da kayan aikin hannu, kayan awo, da sauransu.

(3) Nau'in kayan kwalliyar allura:

Injection mold za a iya raba shi zuwa nau'ikan daban-daban gwargwadon tsarin sifa, ƙirar ƙirar samfur, yanayin samarwa da girke-girke da yanayin amfani.

(a) Maƙallan farantin biyu: a cikin gyare-gyaren allura, mould ɗin da yake motsawa da kuma tsayayyen abin da ya canza shi an raba shi, sannan ana fitar da sassan filastik, wanda aka fi sani da maƙallin farantin biyu. Yana da matukar sauki da kuma na asali roba allura mold. Yana za a iya tsara a matsayin guda rami allura mold ko Multi rami allura mold bisa ga bukatar. Yana da yadu yadu allura mold. Mould for guda ko Multi rami allura gyare-gyaren,

(b) Nau'in farantin karfe guda uku: wanda aka fi sani da suna raba biyu. Idan aka kwatanta da juzu'in allurar waje na waje, daddawar tsaga ta tsaga biyu tana kara wani dan karamin motsi mai motsi a cikin kayan gyara wanda aka gyara don mashigin aya. Saboda tsarinta mai rikitarwa da tsadar masana'anta, gabaɗaya baya amfani dashi a cikin manyan sassan.

(c) Tsarin mai gudu mai zafi: mai tsaran mai gudu mai zafi yana nufin ƙirar da take amfani da na'urar dumama wuta don yin narkar a cikin tashar ba ta ƙaruwa koyaushe. Saboda yana da inganci fiye da yadda ake samarda buzu na gargajiya, da kuma karin kayan adanawa, don haka mai saurin gudu mai tsayi a cikin kasashe da yankuna masu cigaban masana'antu yanzu ana amfani dasu sosai. Tsarin tsere mai zafi yana da tsarin tsere ɗaya mai zafi fiye da kayan masarufi, don haka farashin yayi tsada.

(d) Nauyin launi biyu: gabaɗaya ana kiransa da nau'ikan kayan filastik iri biyu a cikin inji mai allura da allura da allurar gyare-gyare, gyare-gyare biyu, amma samfurin yana sau ɗaya kawai. Gabaɗaya, ana kiran wannan aikin gyare-gyaren sau biyu, wanda yawanci ana kammala shi ta saitin ƙirar, kuma yana buƙatar injin inji mai launi biyu mai launi biyu.

(4) Tsarin gine-ginen ƙwayar allura kamar haka

Tsarin allura gabaɗaya an haɗa shi da ƙananan tsarin-masu zuwa:

(a) Tsarin cin abinci. Yana nufin tashar kwararar filastik a cikin sifa daga bututun allura zuwa rami. Tsarin wasan kwaikwayo na yau da kullun ya ƙunshi sprue, mai rarrabawa, ƙofa da rami mai sanyi.

(b) Rabuwa gefe da kuma tsarin jan hankali.

(c) Tsarin jagoranci. A cikin filastik filastik, galibi yana da aikin sanyawa, jagora da ɗaukar wasu matsin lamba na gefe don tabbatar da daidaito na motsi da tsayayyen ƙyallen maƙala. Tsarin jagorar mutuwar mutu yana kunshi ginshiƙan jagora, hannun riga ko jagorar rami (an buɗe kai tsaye akan samfuri) da saman mazugi.

(d) Ejection / demoulding inji. Ciki har da tura fitar da mahimmin jan inji. Ana amfani dashi galibi don fitar da sassan daga sifar. Ya kunshi sandar ejector ko bututun bushewa ko turawa farantin karfe, plate ejector, ejector sandar tsayayyen farantin, saita sanda da jan sanda.

(e) Tsarin kula da yanayin zafin jiki. Sanyi da na'urorin dumama.

(f) Tsarin shaye shaye.

(g) Abubuwan gyaran abubuwa suna nuni zuwa gaɓoɓin da ke haifar da ramin mould. Yawanci ya hada da: naushi, mace ta mutu, cibiya, sandar kafa, sanya zobe da sakawa.

(h) Kafaffen sassan da aka sanya. .

(5) Kayan abu don kayan kwalliya

Filastik na roba ya haɗa da sifofin thermoplastic da kuma filastik filastik thermosetting. Da karfe don roba mold ake bukata don samun wasu kaddarorin kamar ƙarfi, taurin, ci juriya, thermal kwanciyar hankali da kuma lalata juriya. Bugu da kari, ana kuma buƙatar samun kyakkyawan aiki, kamar ƙaramin magani mai zafi, aikin aiki mafi kyau, mafi ƙarancin lalata, mafi kyau nika da gogewar aiki, ingantaccen aikin walda, ƙarancin ƙarfi, kyakkyawar yanayin zafin jiki da daidaitaccen girma da siffar aiki yanayi.

Wani nau'in kayan allura da ake amfani da shi a cikin ingin mai allura yana da tasirin gaske akan zabin karafan karfe. Idan an ƙara wakili na ƙarfafawa ko wani wakilin gyara, kamar gilashin gilashi, lalacewar abin yana da girma, don haka ya kamata a yi la’akari da zaɓin kayan sosai. Plasticananan kayan filastik acid sune PVC, POM, PBT; kayan roba masu rauni acid sune PC, PP, PMMA, PA. Gabaɗaya, ana zaɓar S136, 1.231, 6420 da sauran ƙarfe da aka zana don robobi masu lalata lalatattu, yayin da S136, 1.2316420, SKD61, NAK80, pak90718, da sauransu ana iya zaɓar don robobi masu lalata lalatattu. Bayyanannun bukatun samfuran suma suna da tasiri mai yawa akan zaɓi na kayan mould. Don sassa masu haske da samfuran tare da goge saman madubi, kayayyakin da ake dasu sune S136, 1.2316718, NAK80 da pak90420. Samfurin da ke da cikakkiyar buƙatun gaskiya ya kamata ya zaɓi S136, ya biyo bayan 420. Idan kawai ya cika buƙatun samfur ba tare da la'akari da farashi da farashi ba, maiyuwa bazai zama mai ƙirar kirki ba, ƙirar ƙirar ƙira ita ce babban fifiko

2.1njection kayan kwalliya

(1). Allura gyare-gyaren inji:

shi ne babban kayan aikin gyaran don yin thermoplastic ko thermosetting robobi zuwa siffofi daban-daban na kayayyakin filastik ta hanyar gyare-gyaren filastik Maƙallan Injin ingila na kwance, injin gyare-gyaren tsaye, injin inji mai launi biyu, cikakken inji mai yin allurar lantarki Duk da haka, ko da wane irin Injin gyare-gyaren allura, ayyukanta na asali guda biyu ne:

(a) Zafafa robobi don narkewa.

(b) Ana amfani da matsin lamba sosai akan narkakken robar don fiddawa da cika ramin. Babban sigogi na allura gyare-gyaren inji su ne: clamping force, matsakaicin allurar girma, matsakaici da kuma kalla mold kauri, motsi bugun jini, ja sanda tazara, ejection bugun jini da ejection matsa lamba. Ga sassan da ke da girma daban-daban, tsari da kayan aiki, kazalika da kayan kwalliya na masu girma dabam da iri daban-daban, yakamata a zaɓi samfuran daban-daban da sigogi na inji mai yin allura. Cikakken injin inki na lantarki yana da fa'idodi na saurin saurin allura, madaidaicin iko da kuma ingancin aikin samarwa. Ana amfani da allura gyare-gyaren wasu daidaici sassa.

(2) Mataimakin kayan aiki:

(a) Mai sarrafa injin inji mai inki kayan aiki ne na atomatik wanda zai iya kwaikwayi wasu ayyuka na gabobin jikin mutum, kuma zai iya sarrafa shi ta atomatik don jigilar kayayyaki ko aiki da kayan aiki bisa ga ƙayyadaddun bukatun. Mai sarrafawa na iya tabbatar da daidaito na sake zagayowar aiki, haɓaka ƙimar kuma sanya shi aminci. Tare da m ci gaban masana'antu roba masana'antu a kasar Sin, da mataki na aiki da kai na allura gyare-gyaren kayan aiki da aka zama mafi girma da kuma mafi girma. Injinan gyare-gyaren inji na zamani galibi ana amfani da su tare da mananda don inganta ƙimar samarwa.

(b) Mai hita / mai sanyaya ruwa: dumama ko sanyaya ta ruwa mai gudana ta cikin kayan kwalliya, kara yawan zafin jiki, inganta yanayin farfajiya, ko rage saurin zafin jikin mutum don inganta yawan aiki.

(c) Dehumidification bushewa: cire danshi daga kayan filastik ta hanyar dumama da busawa.

Injection mold bitar

Alura gyare-gyaren samar line

Plastics sassa zanen layi

3.Plastics kayan

Gudun filastik da aka yi amfani da su a cikin inginin allura: A ƙasa akwai sanannun thermoplastics da ake amfani da su a cikin allurar gyare-gyare: Acrylonitrile Butadiene Styrene, Acrylonitrile Butadiene Styrene (ABS), ita ce mai ɗaukar hoto da amorphous polymer. ... Polyethylene. ... Polycarbonate. ... Polyamide (Nylon) ... Babban Tasirin Polystyrene. ... Tsarin roba

| Kayan aiki | Yawa | Mould Ragewa |

Fasali | Aikace-aikace |

| Darasi / cm3 | % | |||

| ABS(Acrylonitrite Butadiene Styrene) | 1,04 ~ 1,08 | 0.60 | Matsakaici mai kyau, kyawawan kayan aikin inji,sauki electroplating, sauki allura gyare-gyaren | filastik gidaje don kayayyakin lantarki |

| PC (Polycarbonate) | 1.18 ~ 1.20 | 0.50 | Kyakkyawan ƙarfin tasiri, daidaitaccen girma da kyakkyawan rufi.Rashin ƙarfin lalata lalata da juriya ta lalacewa | gidan filastik, murfin kariya, ƙananan sassan watsawa don samfuran lantarki, kayan lantarki |

| PMMA(Polymethyl methacrylate) | 1.17 ~ 1.20 | 0.60 | Yana da kyakkyawar watsawa na kashi 92% kuma ingantaccen ingantaccen ƙarfin inji.Impactarfin tasiri mai ƙarfi yana da ƙasa, mai sauƙi don damuwa fatattaka | Ruwan tabarau mai nunawa da gumakan bugun kira na kayan aiki |

| PP(Yanayi) | 0.89 ~ 0.93 | 2.00 | Yana da ƙarancin raguwa, ƙarfin juriya,high zazzabi juriya kuma ba sauki a tsage.Low Wear juriya, mai sauƙin tsufa, ƙarancin yanayin zafin jiki mara kyau | Kwantena abinci, tebur, akwatinan wutar lantarki na microwave, kwantena na likita |

| (chloride) | 1.38-1.41 | 1.50 | Tauri, sawa-resistant, mai kyau rufi, samar da mafi wahala, rashin ingancin aikin zafin jiki | Yin bututu da bayanan martaba |

| Nylon | 1.12 ~ 1.15 | 0.7-1.0 | Mai wuya, lalacewa, mai jure ruwa, gajiya mai juriya, mai kyau rufi. Babban raguwa, shugabanci | Sassan inji, sassan sinadarai, watsa sassa |

| POM (Polyacetel) | 1.42 | 2.10 | Kyakkyawan kayan aikin inji, babban ƙarfi da tauri, sa juriya da tasirin juriya. Matsayin kwanciyar hankali mara kyau | Sassan inji, sassan sinadarai, sassan watsawa, sassan gogayya da sassan turawa da ke aiki a dakin da zafin jiki |

| TPU(Thermoplastik Polyurethane) | 1.05 ~ 1.25 | 1.20 | Elastomer, lalacewa mai jurewa, mai jure mai, haɓakar zafin jiki mai girma da ƙananan, mara guba | Amfani dashi da yawa a likitanci, abinci, kayayyakin lantarki da ƙananan yanayin zafin jiki |

Tsarin gyare-gyaren allura hanya ce da aka narkar da kayan narkewar da aka narke, allura, sanyaya kuma aka raba su don samar da wani nau'i na bangarorin da aka gama dasu. A general allura gyare-gyaren aiwatar da filastik sassa yafi hada 7 matakai. : Saitin sigogi -> rufe ƙugu-> Cika -> (an taimaka da gas, an taimaka ruwa) matsa lamba riƙewa -> sanyaya -> buɗe buɗa -> lalatawa.

Sauri, matsin lamba, matsayi (bugun jini), lokaci da yanayin zafin jiki sune maɓallan maɓalli guda biyar na aikin gyare-gyaren allura. A cikin samar da gyaren allura, galibi ya zama cire kuskure ga waɗannan sigogin don haɓakawa da samun ƙimar girma da bayyanuwa.

Bakwai na al'ada allura gyare-gyaren fasaha

1. Yin gyare-gyare sau biyu

2. Yin allura fiye da kima

3. Hot gudu mai gudu allura gyare-gyaren

3. IMD: allurar ado in-mold

4. Allurar manyan sassa

5. Allurar gyare-gyare na sassa masu haske

6. Gwanin allura na sassan mota

7. Sashin sassan bango na bakin ciki

Post aiki

Zamu iya samar muku da kayan kwalliyar roba da aka sanya su a cikin polymer mai inganci da yawa kuma a cikin nauyin 0.1gram-10kgs da kuke buƙata. Bugu da kari, zamu iya sanya abubuwan sakawa masu hade-hade, masu haushin karafa na karfe ko wasu allurar roba da aka sanya su don bawa samfurinku ƙwarewar sana'a. Hakanan za'a iya ƙirƙirar ƙananan majalisu a zaman wani ɓangare na ayyukan gyaran allurar filastik ɗinmu kuma an saka su cikin buƙatunku. Hakanan ya shafi matakai daban-daban na kammalawa, gami da:

* Chrome na roba

* Zane

* Hoton hoto

* Bugawan bugawa

* Rariyar RF

* Marufi da sata

* Ingantaccen gyare-gyaren allura Muna kuma ba da kayan aiki mai sauri, samfur da kuma ayyukan gyare-gyaren post.

Gyara lahani da gyara matsala

Bayan gyare-gyare, akwai wasu bambance-bambance tsakanin sassan filastik da ƙayyadaddun ƙimar inganci (ƙididdigar dubawa), waɗanda ba za su iya biyan buƙatun aikin gaba ba. Wannan lahani ne na ɓangarorin filastik, wanda galibi ana kiransa matsaloli masu inganci. Yakamata muyi nazarin dalilan wadannan lamuran sannan mu rage su zuwa mafi karanci. Gabaɗaya magana, waɗannan lahani ana haifar da su ta fuskoki masu zuwa: mould, albarkatun ƙasa, sigogin tsari, kayan aiki Muhalli da ma'aikata.

1. Babban lahani:

(1). Bambancin launi: idan launin kayan gyaran allura ya banbanta da samfurin daidaitaccen samfurin ta idanun tsirara, za'a yanke hukunci azaman banbancin launi ƙarƙashin asalin haske mai daidaituwa.

(2). Rashin cikawa (rashin mannewa): sassan kayan allurar basu cika ba, kuma akwai kumfa, ɓoyi, ramuka masu ragi, da sauransu, waɗanda basu dace da daidaitaccen samfurin ba, wanda ake kira ƙarancin manne.

(3). Warping nakasawa: siffar sassan roba za su juya su karkatar bayan demoulding ko a wani lokaci na gaba. Idan madaidaiciyar gefen ta fuskanto ciki ko waje, ko kuma shimfidar shimfidar tana da hawa da sauka, idan kafar samfurin ba daidai take ba, ana kiranta nakasawa, wanda za'a iya raba shi zuwa lalacewar gida da kuma lalacewa baki daya.

(4). Alamar layin Weld (Lines): alamun layi-layi a saman sassan filastik, wadanda aka kirkira ta hanyar hadewar robobi a cikin sifar, amma ba a cika narkar da su gaba daya a mahadar su ba, don haka ba za a iya hade su da daya ba. Yawancinsu layi ne madaidaiciya, masu tasowa daga zurfin zuwa zurfin. Wannan lamarin yana da wani tasiri akan bayyanar da kayan inji.

(5). Ripple: farfajiyar sassan kayan allura yana da karkace ko gajimare kamar waviness, ko kuma a cikin samfurin mai haske yana da yanayin wavy, wanda ake kira pleanƙara.

(6). Sama gefen (walƙiya, Cape).

(7). Bambancin girma: raguwa da kuma warpage na allurar da aka yiwa kayan gyara a cikin aikin gyare-gyaren

2. Kula da inganci da haɓakawa: Ya haɗa da fasaha da gudanarwa

(1). Matakan fasaha: madaidaicin zaɓi na kayan aiki, ƙirar tsarin samfuri, zaɓin kayan kwalliyar da suka dace, haɓaka ƙirar ƙirar ƙira don sauƙaƙe cikawa, shaye-shaye da ɓangarorin sassa, saitin daidai na rabuwar ƙasa, tashar kwarara da mashigar roba; amfani da kayan aikin gyare-gyare na allura mai mahimmanci ko tsari.

(2). Matakan gudanarwa: kula da inganci na kayan da ke shigowa, kirkirar ingantattun manufofi da ka'idoji, horar da fasaha, kirkirar ingantattun bayanai dalla-dalla, rikodin bayanai da nazari, da kafa tsarin ingancin sauti.

Kamfanin Mestech yana samar da daruruwan kayan kwalliya da miliyoyin kayayyakin roba ga kwastomomin gida da na duniya a kowace shekara. Idan kana so ka san ƙarin ko tambaya game da zance game da gyaran allurar filastik, don Allah tuntube mu a yau.