Mould yin

Short Bayani:

Mould yin (Mutuwar mutu'a) tsari ne na kera kayan aikin gwargwadon zanen zane, ta hanyar amfani da yankan inji, da walƙiya, da gyaran jiki da kuma maganin zafi, kuma daga ƙarshe haɗar dukkan ɓangarorin cikin sifa bisa ga zane zane.

Mould yin & masana'antu ne mai matukar muhimmanci masana'antu a cikin zamani masana'antu masana'antu. Yana bayar da mahimman kayan aiki don manyan-sikelin, ingantaccen aiki da ingantaccen kayan masana'antu.

Menene kwalliya?

Mould (mould, die) an san shi da "uwar masana'antu", wanda shine mahimmin kayan aiki na tsari don samun daidaito mai kyau, inganci mai kyau da kuma samar da babban sikelin a masana'antar masana'antar zamani. A cikin samar da masana'antun masana'antu, ana amfani da kayan kwalliya da kayan aiki daban-daban don samun samfuran da ake buƙata ta hanyar allura, busa ƙaho, extrusion, simintin gyare-gyare ko ƙirƙirawa, narkewa, hatimi da sauran hanyoyin. A takaice, mould kayan aiki ne da ake amfani da su wajen hada abubuwa. Wannan kayan aikin an hada shi da bangarori daban-daban, kuma nau'ikan kayan kwalliya daban daban an hada su da sassa daban-daban. Yawanci yana fahimtar sarrafawar surar abun ta hanyar canza yanayin yanayin abin da ake samu. An san shi da "uwar masana'antu".

Menene masana'antar sifa?

Kusan dukkanin kayan kwalliyar an yi su ne da karfe, kuma kashi 90% daga cikinsu an yi su ne da karfe.

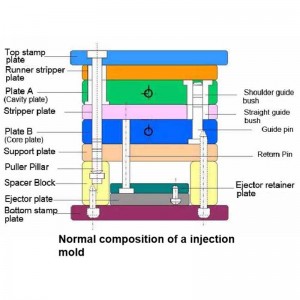

Arkashin aikin ƙarfin waje, tallan ƙarfe ya zama kayan aiki na masana'antu tare da takamaiman fasali da girma. Ana amfani dashi ko'ina a cikin shaƙatawa, ƙirƙirar ƙira, fassarar sanyi, extrusion, ɓangaren ƙarfe na ƙarfe na matsi, matsin lamba, da injunan robobi na injiniya, roba, yumbu da sauran kayayyakin matsewa ko gyare-gyaren allura. Mould din yana da takamaiman kwane-kwane ko siffar ramin ciki, kuma ana iya raba blank daidai da yanayin kwane-kwane (blanking) ta amfani da yanayin kwane-kwane tare da gefen. Za'a iya amfani da sifar ramin ciki don samun madaidaicin siffa mai girma uku na ƙwallon ƙafa. Mould gaba ɗaya ya haɗa da sassa biyu: mould mold da tsayayyen mold (ko naushi da concave mold), wanda za'a iya raba shi kuma ya haɗu. Lokacin da sassan suka rabu, ana yin allurar a cikin ramin ƙira don samarwa lokacin da aka rufe su. Mould shine ainihin kayan aiki tare da fasali mai rikitarwa kuma yana ɗaukar ƙarfin kuɗaɗen ɗimbin billet. Yana da manyan buƙatu akan ƙarfin tsarin, taurin kai, taurin ƙasa, yanayin yanayin ƙasa da daidaitaccen aiki. Matsayin ci gaba na samar da mold shine ɗayan mahimman alamu na ƙirar ƙirar ƙira.

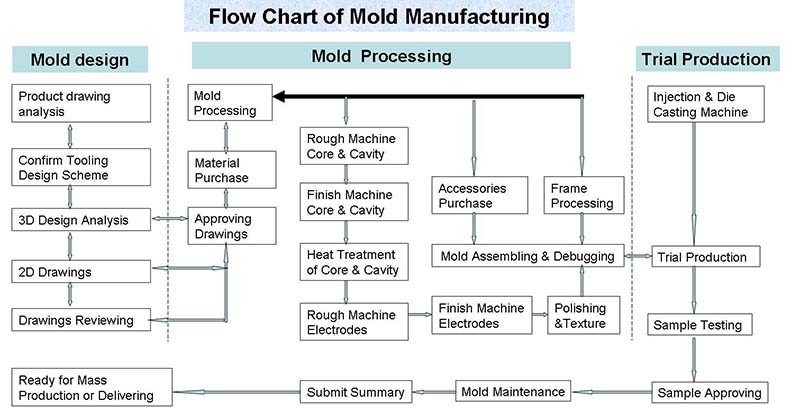

A tsari na mold masana'antu hada da: mold zane, mold aiki, duba duba da kuma gwajin harbi, mold gyare-gyare da kuma gyara, da kuma mold tabbatarwa.

Mold Manufacturing processing yawanci ana samun sa ne ta hanyar ƙirƙirawa, yankan, maganin zafi da haɗuwa da sauran matakai. Don tabbatar da ingancin ƙirar ƙira da rage ƙimar samarwa, kayan yakamata suna da ƙyau mai kyau, yankan kayan aiki, ƙarancin ƙarfi da karawa, kuma yakamata su sami ƙaramin hadawan abu da iskar shaka, ƙwarewar decarbonization da kuma hucewar nakasassu. Yankan yanayi yana ɗaukar kashi 70% na nauyin aikin sarrafa mould. Mataki mafi mahimmanci shine samun rami wanda ya cika buƙatun fasali, ƙimar girma da ƙimar ƙasa, da kuma dukkan hanyoyin.

Tsarin samar da mold

Rolledarfe na baƙin ƙarfe don yin ƙwanƙwasa an birgima kuma an ƙirƙira shi a cikin masana'antar ƙarfe, kuma tsire-tsire na zamani zai iya zaɓar siye kai tsaye. Mold yin shine sanya waɗannan blanks ɗin ƙarfe a cikin ƙirar da za su iya samar da samfurori a cikin samar da taro. A yi na mold hada da mold zane, machining da kuma taro na mold core da kuma mold tushe.

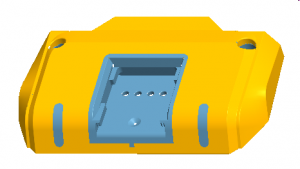

1. Mold design an gama shi da kwararrun injiniyoyi. Mold design ne misali da kuma tushen dukan mold samar. Dangane da bukatun samfurin tsari da girman farfajiyar fuska, lokutan aikace-aikace da fitowar da ake tsammani, gami da daidaitawar injin gyare-gyaren allura, dole ne injiniyan ya zabi karfe da kyau don kowane bangare na kayan kwalliyar kuma ya tantance tsarin da tsarin molin. Amintaccen tsarin ƙira yana ƙayyade wahalar masana'antu, tsada, rayuwar sabis, yawan aiki da ƙimar samfurin ƙirar.

Mould wani nau'i ne na kayan aiki masu tsada. A cikin ƙirar, injiniyoyinmu suna amfani da software don yin nazari da yin kwatankwacin rarraba sassan, hanyar kwarara, wurin allura har ma da tsarin sassan.

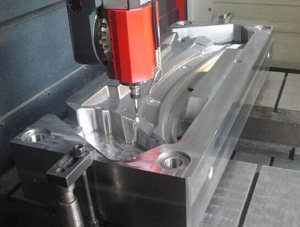

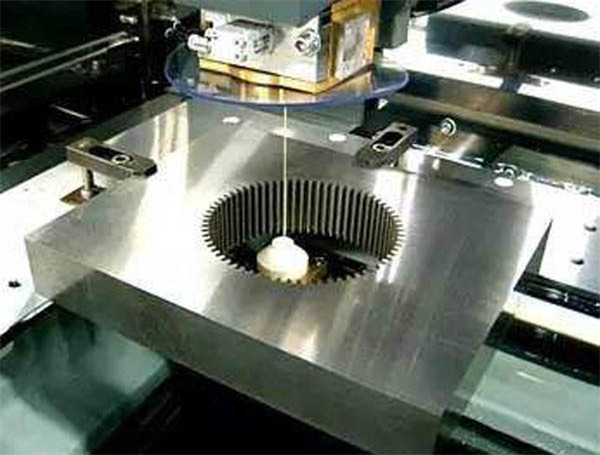

2. Kirkirar kayan kwalliya. Ana sarrafa billetin mould ta kayan aiki na inji bisa ƙirar injiniyan da takardun aikin. Gabaɗaya, kayan aikin yankan inji da kayan aikin da ake amfani da su don haɗawa sun haɗa da CNC, EDM, WEDM, lathe, injin niƙa, injin goge, da dai sauransu. Kayan aikin masarufi na ƙwarai da gaske na iya inganta haɓakar ƙirar ƙwarai, taƙaita tsarin samarwa da rage farashin. Nau'ikan nau'ikan nau'ikan kayan kwalliya daban-daban suna amfani da kayan haɗi daban-daban na kayan aikin inji: ƙirar allura da ƙirar masu mutuƙar zuga sau da yawa suna amfani da CNC, EDM da WEDM. Ararin zoben da kuma kayan kwalliyar extrusion sukan yi amfani da CNC da WEDM

3. oldungiyar taro. Haɗin haɗin ginin ya dogara da masu fasaha. Ya haɗa da mutuƙar mutu'a, toshe faifai, jagorar jagora, hanyar fiddawa, daidaitawa tsakanin firam ɗin mutu da mota, taron mai gudu mai zafi, da ɓangaren da ba za a iya yankewa ba, da taron ƙarshe na ƙarshe. Mafi girman daidaito na aikin inji, ƙaramin aikin aikin taron mutuƙar, da gajarta sake zagayowar samarwa da ƙananan farashin. Bayan kammala taron mutuƙar, ya zama dole a gwada, a tabbatar, cire kuskure da inganta mutuƙar har sai ta iya samar da ƙwararrun samfura tare da wasu adadi.

Hankula mold yin tsari

Injin CNC

EDM-Injin Wutar Lantarki

WEDM-waya yankan lantarki

Daidaitawa da tara kayan aiki

Kamfanin na Mestech yafi tsunduma cikin kera filastik kayan kwalliya da allurar samfura, da kuma kyawon kayan masarufi (karfe mai mutu-simintin mutu, stamping die) masana'antu da kayan sassan karfe.