Filastik overmolding

Short Bayani:

Filastik overmoldingwani tsari ne na musamman da ake yin allura, wanda ake amfani dashi don hada bangarorin kayan guda biyu zuwa bangare daya ta hanyar hada allura. An rarraba sassan biyu sau biyu a cikin nau'ikan daban-daban da injin inginin allura.

Filastik a kan gyare-gyare tsari ne don sanya ɗaya ko fiye da sassan filastik na abubuwa daban-daban a cikin ƙwayar allurar kafin allurar, sannan allurar roba da aka sanya a cikin ƙwanƙolin, murfin kayan allurar ko kunsa ɓangarorin da aka zaba su zama ɓangare ɗaya.

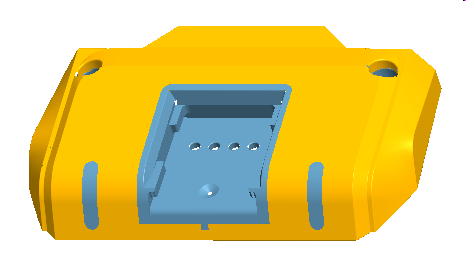

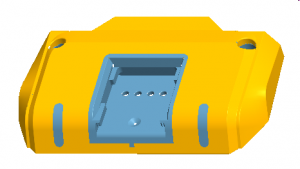

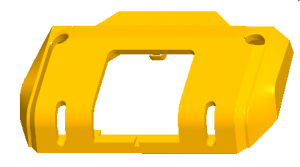

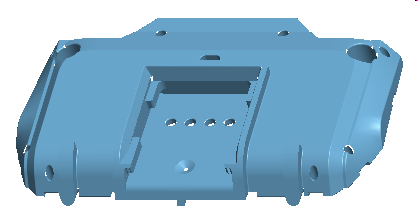

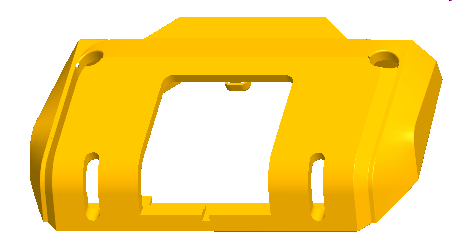

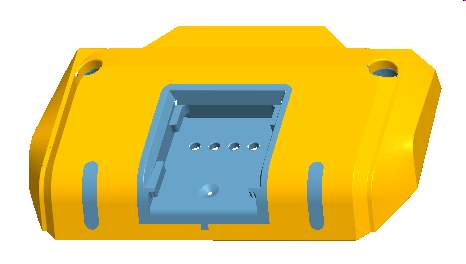

Mataki na farko: shirya sashin da aka riga aka sanya. (Mold1)

Mataki na biyu: sanya abin da aka riga aka sanya shi a cikin infin ingin, kuma a yi shi da yawa tare da guduro na filastik. (Mold2)

Sashin filastik na ƙarshe

Akwai nau'ikan nau'i biyu akan gyare-gyaren

Nau'in 1: Abubuwan da aka riga aka sanya / kayan haɗin sune filastik, waɗanda a baya aka halicce su a cikin wani ƙirar. Wannan hanyar ta haɗa da gyare-gyaren allura biyu. Wannan filastik ne akan gyaran da muka tattauna anan.

Nau'i na 2: Abubuwan da aka sanya su ba filastik bane, amma suna iya zama ƙarfe ko wasu sassa masu ƙarfi (misali kayan lantarki). Muna kiran wannan tsari saka gyare-gyaren.

Yawancin lokaci sassan da aka riga aka zana an rufe su gaba ɗaya ko kuma an rufe su gaba ɗaya ta kayan da suka biyo baya (kayan filastik) a cikin aikin gyaran kan-kan.

Shin kun san aikace-aikacen filastik akan gyare-gyare?

Akwai dalilai da yawa don filastik akan gyare-gyaren. Mafi shahara a cikinsu sune:

1. colorara launi don kawata bayyanar (tasirin ado).

2. Samar da yankin riƙewa mai sauƙi a ɓangaren.

3. flexibleara yanki mai sassauƙa zuwa sassa masu tsauri don ƙara haɓaka da taɓa taɓawa.

4. materialara kayan roba don rufe samfurin ko hatimi don tabbatar da ruwa.

5. Ajiye lokacin taro. Babu buƙatar haɗa ɓangaren ƙarfe da ɓangaren filastik da hannu ko ta atomatik. Kuna buƙatar kawai sanya ɓangaren kayan aiki a cikin sifa kuma yi allurar sashin filastik. Babu buƙatar tara shi kwata-kwata.

5. Gyara wani sashi a cikin wani ba tare da amfani da abin sakawa ko mannewa ba.

Wane irin samfuran roba ne akan kayan kwalliya sun dace da su?

A roba kan-gyare-gyaren tsari ya dace wa mutane da yawa kayayyakin, wanda ya bambanta dangane da takamaiman yanayin da kayayyakin. Yawancin lokaci sun haɗa da buroshin goge baki, kayan aikin kayan aiki (kamar su atisayen mara waya da sihiri) da kayayyakin kulawa na mutum (kamar kwalayen shamfu da aski), tashar waya, matosai, masu riƙe katin SIM, da dai sauransu.

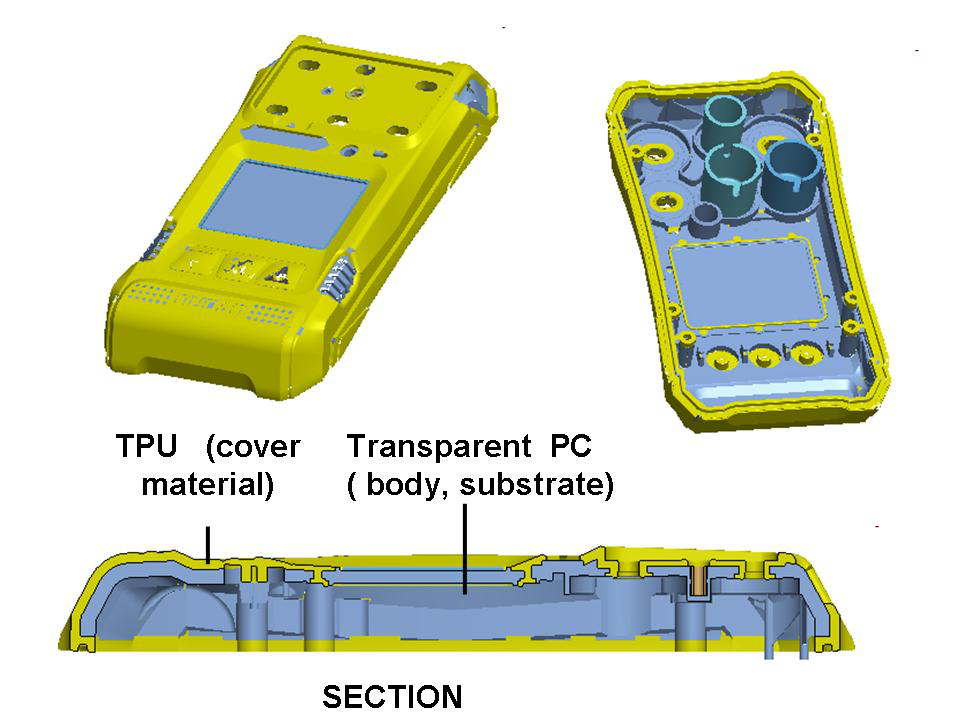

PC & TPU overmolding hana ruwa hali

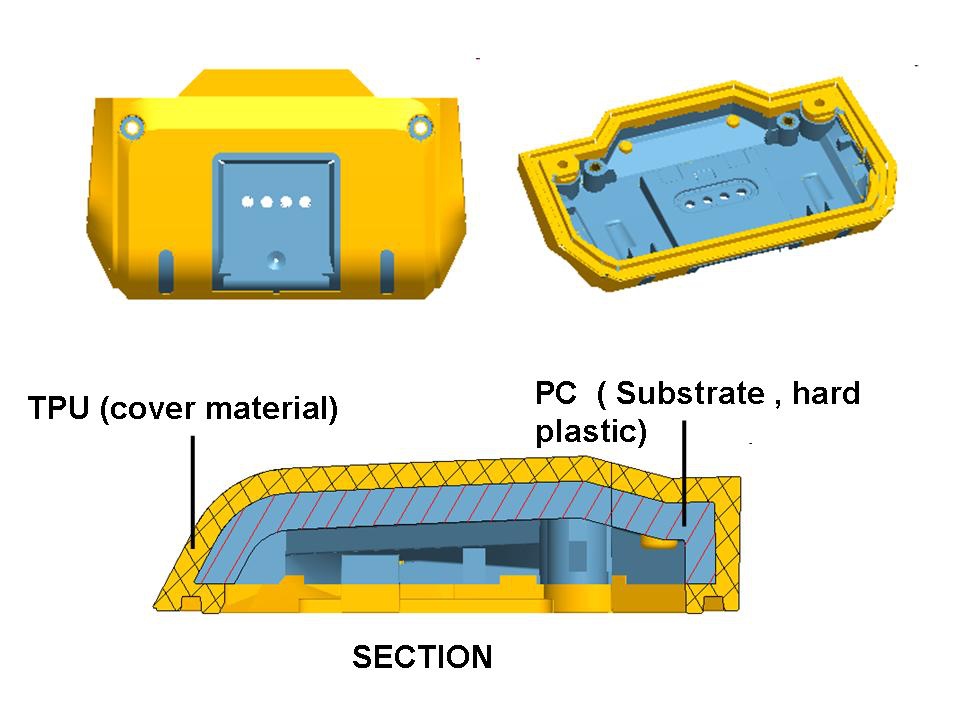

PC & TPU overmolding ƙofar baturi mai hana ruwa

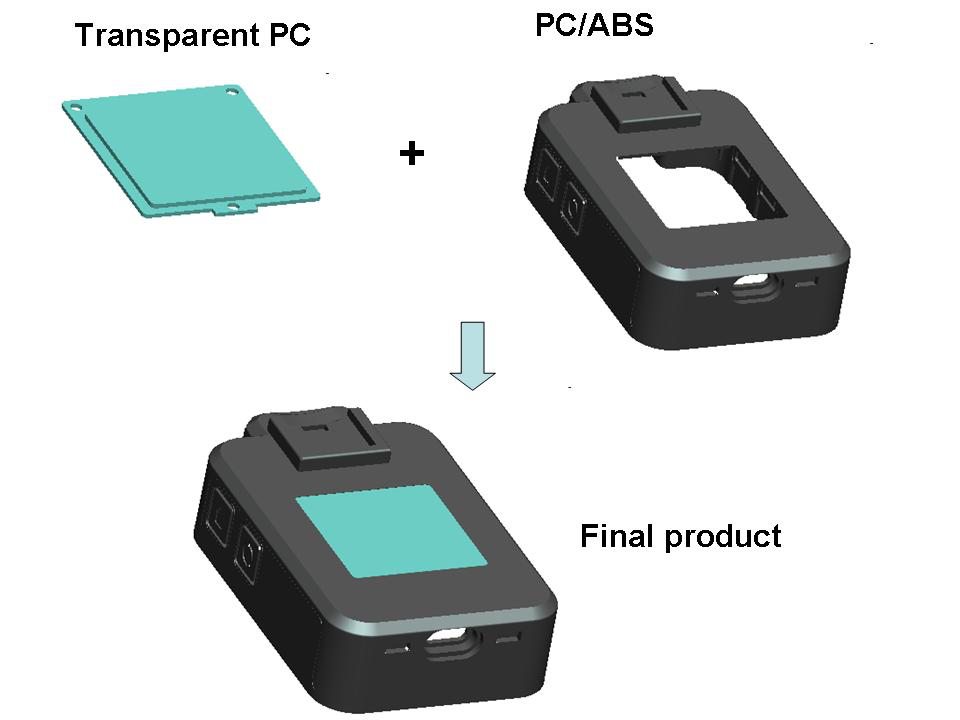

PC & PC / ABS overmolding roba hali ga lantarki samfurin

PC & TPU overmolding shari'ar kariya ga wayar hannu

Launi biyu girman girma overmolding filastik bangare

ABS & TPE overmolding dabaran

Anan akwai wasu misalai na al'ada akan aikace-aikacen gyare-gyare:

1. Hard roba mai rufe filastik - da farko dai, an kafa wani tsayayyen sashin filastik wanda aka riga aka sanya shi wuri. Sannan kuma ana yin wata allurar roba mai taushi a kusa ko kusa da sassan da aka riga aka sanya su. Robobi na iya bambanta da launi da / ko resin.

2. Hard plastic da aka nannade a cikin lamin elastomer mai taushi - na farko, an riga an sanya sassan filastik masu tauri. Elastomer resin (TPU, TPE, TPR) ana sanya shi a kan ko kusa da sassan da aka riga aka sanya shi. Wannan yawanci ana amfani dashi don samar da yanki mai laushi mai hannu don sassa masu tsauri.

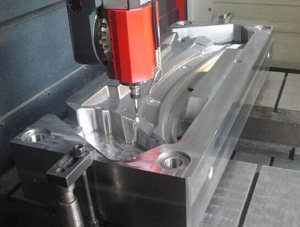

3. Karfe da aka nade da filastik - da farko dai, asalin ƙarfe ana yin inji ne, jifa ko siffa. Bayan haka, an saka sassan da aka riga aka sanya a cikin ramin inkin ingin, kuma ana yin filastik ɗin a ciki ko kusa da ƙarfen. Wannan galibi ana amfani dashi don ɗaukar sassan ƙarfe a sassan filastik.

4.Elastomer resin yana rufe Karfe - Na farko, ɓangaren ƙarfe yana da inji, j castfa ko siffa. Sa'annan an sanya sassan karfe wadanda aka riga aka sanya su a cikin infin allurar kuma an saka gudan elastomer a kan ko kusa da ƙarfen. Wannan yawanci ana amfani dashi don samar da laushi mai laushi, da kyau.

5. Soft elastomer resin nada PCBA ko kayan aikin lantarki, module emitting module, da sauransu

Yana da mahimmanci a lura cewa akwai wasu iyakoki da matsalolin daidaitawa tsakanin abubuwa daban daban waɗanda suke buƙatar la'akari da jujjuyawar abubuwa. Ba a iyakance ka da kayan aiki iri biyu ba. Mun ga wasu samfuran, a wani sashi tare da rawanin filastik daban-daban guda uku waɗanda aka haɗu don cimma daidaitaccen launi tsakanin juna. Ga misali mai sauki na samfurin da zaku saba dashi sosai: almakashi.

Yawancin lokaci, ana sanya kayan ɓangaren da aka riga aka sanya ko ɓangarorin a cikin kyandir ɗin allurar, a wannan lokacin ana yin allurar filastik ɗin da aka yi ƙwanƙwasa cikin ko kewaye sassan da aka sanya su. Lokacin da kayan allurar da aka lullubeta suka sanyaya kuma suka warke, sai a hada kayan biyu waje guda don zama wani bangare mai mahimmanci. Tipsarin haske: Yawancin lokaci yana da kyau a sami ɓangarorin da aka riga aka sanya su da kayan da aka ƙintsa su ta hanyar inji. Ta wannan hanyar, ana iya haɗa kayan biyu ba kawai ta hanyar sinadarai ba, har ma da jiki.

Mene ne fa'idar fifikon sarrafawa a cikin samarwa?

A kan gyare-gyaren mold yana da tsari mai sauƙi da sassauƙa tsari.

1. Ya dace da sassan da ke da manyan sassan sutura, musamman sassan da ke da rumfa mai juyewa. Wannan nau'in kayan filastik suna da wahalar yi musu allura a cikin inji mai inji guda biyu tare da launuka masu launi biyu, wanda za a iya cimma shi ta hanyar murfin allurar roba da aka rufe.

2. Lokacin da fasalin saiti mai sauki ya kasance kuma girmansa ƙarami ne kaɗan, kuma ɓangaren ƙarshe yana da girma, ya dace da ɗauka

roba rufe allura gyare-gyaren. A wannan lokacin, za a iya yin sifar madaidaitan ɓangaren ƙarami ko ƙwanƙolin rami mai yawa, wanda zai iya rage yawan kuɗin mould.

3. Lokacin da sassan da aka riga aka sanya su da kayan da aka lullube su duka robobi ne (resins), ana ba da shawarar cewa ya kamata a yi amfani da tsarin hada allura sau biyu wajen samar da taro maimakon wuce gona da iri domin samun inganci mai inganci, inganci mai yawa da kuma tsada. Lokacin da ƙaramin tsari ko buƙatun inganci ba su da yawa, ana iya amfani da overmolding don kauce wa saka hannun jari na injin allura sau biyu da kuma tsadar ƙera kayan ƙira.

Menene kayan da aka sanya sassan farko?

Muna kiran sassan da aka fara sanya su a cikin sifar sassan da aka sanya su (ko sassan da aka riga aka sanya su).

Sassan da aka riga aka sanya su na iya zama kowane sassa mai ƙarfi, ɓangaren ƙarfe da aka ƙera, ɓangaren filastik wanda aka tsara, ko ma samfurin da ake da su, kamar goro, dunƙule, ko kuma mai haɗa lantarki. Wadannan sassan da aka riga aka sanya su za'a hada su da robobi masu allura daga baya don samar da wani bangare guda ta hanyar aikin sinadarai da haɗin inji. Elastomer resins (TPU, TPE, TPR) suma robobi ne, amma basu dace da zama sassan da aka riga aka sanya ba.

Yaya za a zabi resins na filastik don ƙira?

Gilashin filastik waɗanda aka yi amfani da su akan gyare-gyare galibi robobi ne. Suna farawa ne a cikin sifofin ƙura, kuma yawan zafin narkar da su yawanci yana ƙasa da na waɗanda aka riga aka sanya su don hana ɓangarorin da aka riga aka sanya su lalacewa ta babban zafin jiki. An haɗu da waɗannan ƙwayoyin tare da ƙari kamar launuka masu launi, wakilan kumfa da sauran matatun ruwa. Sannan ana zafafa shi zuwa wurin narkewa kuma a yi masa allura a matsayin ruwa. Akwai iyakoki akan kayan da suka dace da gyare-gyare. Idan sassan da aka sanya su sassa ne na ƙarfe, zaku iya amfani da kowane filastik azaman kayan overmolding. Matsalar haɗin kai na iya kasancewa idan an sanya ɓangaren da aka riga aka sanya da wani resin na roba (roba ko TPE) tare da maɓallin narkewa.

Shin kun san inji mai inji don allura?

Injin gyare-gyaren allurar da aka yi amfani da shi a cikin filastik filastik shine na'urar gyare-gyaren allurar gama gari, wacce aka kasu gida biyu: a tsaye da kwance.

1. Injin inji mai tsayayyar tsaye yana da sararin samaniya fiye da injin da yake yin allura a kwance na nauyin daya, wanda ba sauki a kiyaye shi, saboda haka yawanci yawanci karami ne. Musamman dacewa da ƙananan ɓangarori masu girma ko sassan da aka riga aka sanya su ba sauki a gyara su a cikin kayan mol.

2. Na'urar gyare-gyaren allurar kwance tana da babban nauyi da ƙaramar sarari, wanda ya dace da gyaran manyan sassan girma.

Yadda za a zabi allura gyare-gyaren inji for kan gyare-gyaren?

1. Ana amfani da inji mai tsayayyar allurar tsaye don ƙananan sassa kamar tashoshin waya da masu haɗawa, matosai masu ƙarfi, ruwan tabarau da sauransu. Samun suna da sauki da inganci.

2. Ana amfani da inji mai inji na kwance don manyan sassan girma, wanda ke da isasshen ƙarfi kuma yana da son aiki.

3. Ana ba da shawarar gyaran allura masu launuka biyu don sassan da aka riga aka sanya su da kayan da aka saka, wadanda za su iya samun inganci da inganci fiye da yadda ake sanya allura.

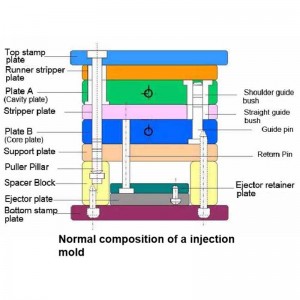

Abubuwan da ke cikin allurar ƙira don sarrafawa

Marfafa yawanci yana da nau'i biyu na ƙirar allura. Isaya shine don gyare-gyaren ɓangaren da aka riga aka sanya, wani ɗayan don ɓangaren ƙarshe ne.

Lokacin da sassan da aka riga aka sanya su ba filastik bane ko kuma basu buƙatar gyarar allura ba, saiti ɗaya kawai ake buƙata. Muna kiran wannan tsari saka gyare-gyaren.

Kamfanin na Mestech yana da gogewa a cikin kayan allura masu sanye da filastik, musamman a cikin kayan allurar da aka sanya masu roba da bawo na kayayyakin lantarki da na lantarki da kayan aiki azaman sassan saiti. Mestech kuma an sanye ta da injina masu yin launuka masu launuka iri-iri, wadanda zasu iya samar da nau'ikan bangarorin roba masu launuka biyu, bangarorin da aka rufu da filastik da kuma kayan inginin. Idan kana bukata, sai ka tuntube mu.