Samfurin ƙarfe

Short Bayani:

Ana yin samfurin ƙarfe koyaushe don injiniyoyi don tabbatar da ƙirar na'urar ko inji. Mestech tana samar da samfurin kwastomomi na kwastomomi.

Samfurin ƙarfekoyaushe ana yin shi ne don injiniyoyi don tabbatar da ƙirar na'urar ko inji. Mestech tana samar da samfurin kwastomomi na kwastomomi.

Ana amfani da sassan ƙarfe don yin daidaitattun sassa da bawo na kayan aiki, kuma sun fi tsada fiye da na ɓangarorin filastik. Domin inganta ƙira da rage haɗarin, ya zama dole ayi samfuran samfuri don ƙira da tabbatar aiki kafin samarwa na yau da kullun.

Ana amfani da sassan ƙarfe a cikin kayan aiki da kayan aiki daban-daban. Yawanci ana amfani dasu don yin daidaitattun sassa saboda yanayin girmansu, ƙarfi da taurin kansu, halaye masu girma da ƙarancin zafin jiki da haɓakar lantarki, waɗanda suka fi ƙarfin sassan filastik.

Idan aka kwatanta da sassan filastik, akwai nau'ikan kayan abubuwa da yawa na sassan karafa, kamar su alloy alloy, alloy alloy, zinc alloy, steel, titanium alloy, magnesium alloy da sauransu, tare da abubuwa daban daban. Daga cikin su, ana amfani da nau'ikan ferroalloys, gami na aluminium, gwal na tagulla da zinc a cikin kayayyakin masana'antu da na farar hula. Waɗannan kayan ƙarfe suna da kayyakin jiki da na sinadarai daban-daban, kuma fasahar sarrafa kayan ƙarfe tare da sifofi da sifofi daban-daban sun sha bamban.

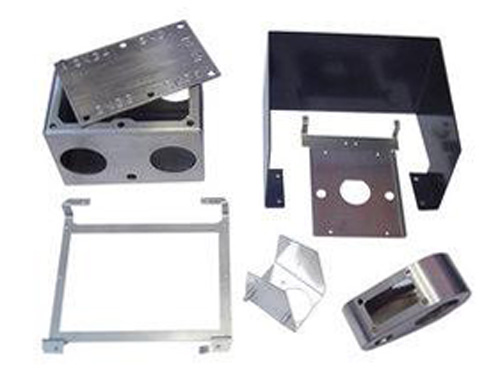

Dangane da kayan da tsarin sassan, akwai nau'ikan samar da kayan masarufi da yawa wadanda ake hadawa dasu don bangarorin karfe, kamar yankan, simintin mutu, yin kwalliya, hada abubuwa, lankwasawa, extrusion da sintering. Don simintin mutu, ɓoyewa, extrusion da ɓarna, ana amfani da ƙirar. Mota yawanci tana nufin saka hannun jari mai tsada, don haka ana amfani da yankan inji don yin samfurin su.

Akwai manyan matakai guda uku don yin samfurin samfurin ƙarfe:

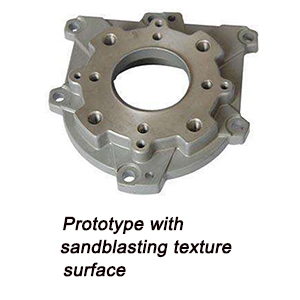

1. Injin.

Yawanci ana amfani dashi don ɓangarori tare da madaidaitan girma da ƙananan sassa.

Babban kayan aikin shine injin nika na CNC, lathe, nika, EDM, WEDM da sauran kayan aikin mashin.

Don sarrafa jirgin sama, farfajiya, tsagi da rami na aksali, hannun riga, faifai, koboda da sassan ƙarfe masu lankwasa.

Ana amfani da kayan aikin inji na musamman na musamman don aiwatar da sassa tare da buƙatun madaidaiciya. Sassa kamar giya, dunƙule sanduna, da dai sauransu.

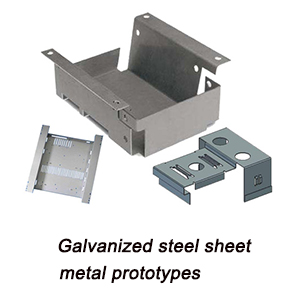

2. Sarrafar karfe

Don kwasfa da kayan kwalliyar da bango na bakin ciki da kauri iri ɗaya ko'ina, ana amfani da tsari na ƙarfe gaba ɗaya, ma'ana, ta hanyar injin yankan laser da wasu kayan aiki masu sauƙi ko kayan aiki ta hanyar lankwasawa, yankanwa, buga tambura da guduma. Ya fi dogara da aikin hannu.

Misali, gidajen mota, kayan kwalliya, da sauransu.

3. Surface Bayan magani

Bayan kayan aiki ko sarrafa farantin karfe, ana samun manyan ƙirar ƙira da siffofi. Domin samun kyakyawan yanayin sama da bayyana, ana bukatar maganin farji sau da yawa.

A. finishingarshen fuska: nika, gogewa, rubutun rubutu, sassaka laser da embossing.

B. Fesa foda, zaba wutar lantarki, hadawan abu da iskar shayi.

Samfurin kayan Aluminium na CNC

Daidaici machined karfe samfur

Samfurori na bakin karfe

Babban taurin, narkakken yanayin zafin jiki yana nuna halaye da kuma daidaitattun abubuwan da ake amfani dasu na kayan karafa suna tantance fasahar sarrafa su daban da ta kayan da ba na karfe ba (kamar su robobi) wajen yin samfura ko samfura. Kamfaninmu yana ba abokan ciniki cikakken kewayon samfurin tsayawa ɗaya ko ƙera kayan izgili da sabis, gami da ɓangarorin filastik, ɓangarorin gel silica, sassan ƙarfe da sauransu. Idan kana bukata, sai ka tuntube mu.