Samfurin yin shine yin samfura ɗaya ko yawa bisa ga zane ko zane na samfurin, ta hanyar wasu hanyoyin sarrafawa na musamman, gwargwadon buƙatun bayyanar samfur da zane-zane ba tare da ƙirar samarwa ba.

Samfurin kusan ɗaya yake da ainihin samfurin a cikin sifa, launi da fasali. Ana amfani dashi don tabbatar ko girman girman haɗin sararin, fasali, siffofin launi da kuma wasu fasalulluka na sabbin kayan da aka ƙera ingantattu ne, ko don nuna samfuran ga abokan ciniki don samun ra'ayin abokan ciniki ko ƙimar kasuwa.

Tsarin rayuwa yana farawa daga zane kuma yana ƙare a kasuwa. Tsarin samfur yana bayyana aiki, bayyanar da amincin samfuran. Ayyade tsari da farashin samfurin. Tsarin samfuri aiki ne mai tsauri, wanda ke da nasaba da nasarar samfuran gabaɗaya. Daga ƙirar samfur zuwa samar da taro na ƙarshe, kowane irin samfurin da aka yi niyya don samar da ɗimbin ɗabi'a yana buƙatar saka kuɗi mai yawa, lokaci da kuzari. Kyakkyawan zane shine mabuɗin nasarar samfuran. Samfurin samfurin samfuri don bincika, tabbatarwa da haɓaka ƙirar samfuri muhimmiyar hanya ce don samun cikakken ƙirar samfuri. Masana'antar hannu zata iya inganta saurin ci gaban samfur

Janar kayayyakin masana'antu, kamar su lantarki, kayan lantarki, motoci da na'urorin kiwon lafiya, ana yin su ne da filastik, kayan aiki ko kayan aikin lantarki. Domin kaucewa mummunan ɓarnar da ke cikin samar da kayan masarufi da samarwa wanda kuskuren ƙira ya haifar, muna yin samfuran ƙira a ƙaramin kuɗi ta hanyar ƙira, ƙirar laser da ƙirar wucin gadi da sauran hanyoyin bincike, haɗuwa da kimantawa, ko nuna su ga abokan ciniki.

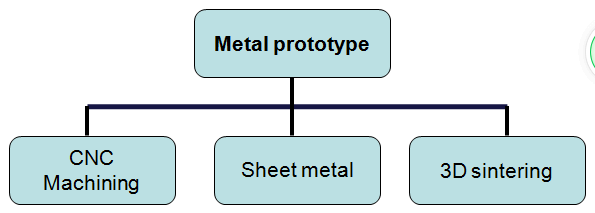

1. Manual samar da karfe samfurin: akwai manyan hanyoyi guda uku don yin samfurin ɓangaren ƙarfe

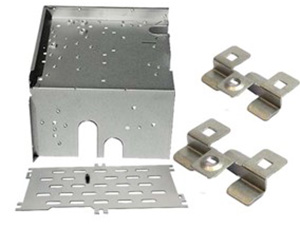

(1). Takaddun karfe: lankwasawa, yankanwa, fitarwa da duka da hannu ko kayan aiki masu sauki. Wannan hanyar ana amfani da ita galibi don ƙirar ƙyallen sassan ƙarfe. Abubuwan da suka dace sun haɗa da ƙarfe, gami na aluminium, ƙarfe na jan ƙarfe da zinc.

(2) Kayan aikin CNC: niƙa, juyawa, nika, sauke da haƙa kayan ƙarfe akan kayan aikin inji. Ana amfani da wannan hanyar don yin bulo da ƙirar kayan ƙera, wani lokacin ramuka ko ƙarewar gida na samfuran ƙarfe suma ana buƙatar a sarrafa su. Abubuwan da suka dace sun haɗa da ƙarfe, gami na aluminium, ƙarfe na jan ƙarfe da zinc.

(3). Bugun 3D mai lasar karfe (sintering): Ana amfani da bugu na 3D na ƙarfe don samar da sassa tare da hadaddun siffofi da sifofi waɗanda ke da wahalar samarwa ta hanyar inji da sarrafa kayan ƙarfe, kamar wukunan injuna, bututu masu sanyaya ruwa, da sauransu. karfe da martensitic karfe, bakin karfe tsarkakakken titanium da gwal titanium, gami na aluminium, gwal din nickel, cobalt chromium gami da tagulla mai hade gami

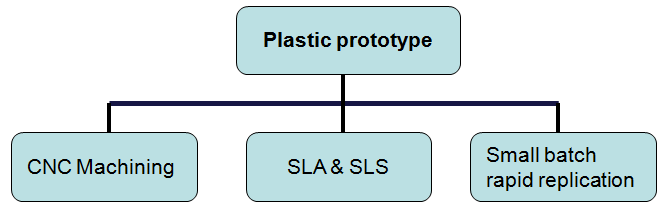

2. Samfurori na filastik: akwai manyan hanyoyi guda uku don yin samfurorin filastik:

(1) .CNC gyare-gyare: wato, blank filastik ana sarrafa shi akan kayan aikin inji. Ana amfani da wannan hanyar don gyaran kwasfa, toshewa da juya jiki. Ana zartar da kusan dukkanin kayan filastik masu wuya.

(2). Laser 3D bugu da sintering (SLA da SLS): ana amfani da SLA don yin samfurin samfura na sassa masu rikitarwa tare da bayyanar CNC mai wuya da tsari, galibi ta amfani da kayan ABS da PVC da ake kira resin mai daukar hoto. Tsarin Laser na SLS shima ya dace da TPU robobi masu taushi wanda CNC ba zai iya sarrafa shi ba, da robobi na injiniya kamar nailan.

(3) .Kananan tsari masu saurin sauri ta hanyar silica gel mold (gami da cika wuri da bakin ruwa): wannan aikin yana daukar samfurin da CNC yayi aiki dashi ko buga shi ta hanyar laser 3D kamar yadda yake, ya zubo da wasu adadi na silica gel, sannan yayi allurar. filastik mai ruwa a cikin ramin silica gel. Bayan an gama warkewa, yanke sinadarin gel silica don samun sassan roba. Abubuwan da akayi amfani dasu don yin sassan sune ABS, PU, PC, nailan, POM da PVC mai taushi

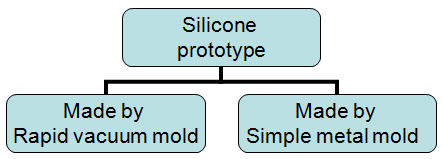

3. Samfurin yin silica gel sassa:

Abun silica gel mai laushi ne kuma yanayin zafin narkar da shi mai sauki ne kuma mai taushi, don haka kwastomomin CNC ko laser 3D ba galibi. Babban hanyoyin don yin samfurin silicone sune ƙarancin buɗaɗɗen tsari da sauƙi mai sauƙi.

Abubuwan da muka yi wa abokan cinikinmu kamar haka :

CNC Samfurin samfura

Samfurin karfe

3D sintering samfoti

Samfurin silikon ta hanyar injin buɗa ido

Kayan kwalliyar CNC

Samfurai masu buga Laser 3D

Samfurori na filastik ta hanyar cika wuri

Samfurin silikon ta hanyar sauƙaƙan tsari

Surface jiyya na samfur

Ciki har da buga 3D, aikin CNC, zana hoton sama, zane da zane na siliki na samfurin ɓangaren filastik.

Ciki har da sassan karfe, gami na aluminium, gami da zinc, kayan bakin karfe da kayan kwalliya, zaban lantarki, hadawan abu da iskar shaka, PVD da sauran jiyya.

Mestech tana da ƙungiyar injiniyoyi da suka kware a ƙirar samfur, suna ba da ƙanana da matsakaitan masana'antu da abokan ciniki tare da sabis na tsayawa guda ɗaya na ƙirar samfur, samar da samfur na samfur, kayan roba da kayan ƙera ƙarfe, samar da yanki da yawa da kuma sayen kayayyaki.