Mutu simintin tsari

Short Bayani:

Mutu simintin tsari shine tsari wanda zinc, copper, aluminium, magnesium, lead, tin da lead gami da allo dinsu suke narkewa a zazzabi mai zafin gaske kuma aka sanyasu cikin kogon da ke jikin mutum, sannan a sanyaya cikin matsi don samun sassan.

Zafin zafin aiki na baƙin ƙarfe mara ƙarfe ya fi na baƙin ƙarfe ƙanƙanci, kuma kayan aikin da aka samo masu daidai da buƙatun tsari suna da sauƙi, kuma ƙarami. Castaddamar da simintin gyaran kafa zai iya samun kyakkyawar ingancin farfajiya da daidaitacciyar sifa, musamman dacewa da ƙirar sikelin sikeli mai ƙanana da ƙananan sifofi, wanda ke ba da kyakkyawar goyon baya ga kayan lantarki na zamani, kayan lantarki, motoci, na'urorin lafiya, kayan kida da kyanwa. kayan aiki. Daban-daban karfe gami da yawa daban-daban hali a mutu simintin tsari. Mafi ƙarancin sashinsu da ƙaramin daftarin sun bambanta, narkakkar zafin zafin yanayi ya bambanta, kammalawar saman daban, Don haka ya fi dacewa a haɗa ƙungiyar injiniyoyinmu da wuri yayin tsarin ƙira don amfani da ƙwarewarmu tare da ƙira don ƙera masana'antu.

Akwai biyar main dalilai a karfe mutu simintin tsari:

1.Die kayan simintin gyare-gyare;

2.Yanayin Matatun Fitar Mutuwa;

3.Die simintin inji;

4.Die simintin gyare-gyare;

5.Posting Processing da Gamawa don Mutu 'yan Wasa sassa

Karfe mutu simintin tsarihanya ce ta daidaita matsi, gudu da lokaci ta amfani da abubuwa uku na inji, sifa da allo. Domin karfe zafi aiki, kasancewar matsin lamba shi ne babban halayyar mutu simintin tsari wanda ya sha bamban da sauran simintin hanyoyin. Gwanin matsin lamba hanya ce ta simintin gyaran kafa ta musamman tare da ragi kuma ba yanke, wanda ya bunkasa cikin sauri a fasahar sarrafa karfe ta zamani. Tsari ne na cika abin da aka narkar da shi da narkakken karfe a karkashin matsin lamba da babban gudu, da kuma yin simintin gyare-gyaren ta hanyar kara kuzari da kuma karfafa shi a karkashin matsin lamba. High matsa lamba da kuma babban gudun ne manyan halaye na mutu simintin. Matsin da aka saba amfani dashi shine dubunnan na megapascals, saurin cikawa (saurin ƙofar ciki) yakai kimanin 16-80m / s, kuma lokacin cikawar ruwan ƙarfe a cikin ramin juzu'i yayi gajere sosai, kimanin 0.01-0.2s. Fitar baƙin ƙarfe tsari ne na yin simintin ƙarfe wanda aka keɓance da tilasta narkakkar ƙarfe ƙarƙashin babban matsin shiga rami mai ƙyalli. An sanya ramin ƙwanƙolin da maɓuɓɓugan ta amfani da tauraron ƙarfe da ya mutu wanda aka sarrafa shi cikin sifa kuma yayi aiki iri ɗaya da maƙerin allura yayin aikin. Dogaro da nau'in ƙarfen da ake jefawa, ana amfani da inji mai ɗumi mai zafi ko sanyi.

1.Die simintin kayanMESTECH yana ba da sassan simintin gyare-gyare don zinc alloy, gami na aluminium da allurar magnesium. Saboda wadannan uku kayan ne mafi yadu amfani mutu Fitar gami kayan a halin yanzu.

Abubuwan haɗin zinc:

--- strengtharfi da tauri

--- Kyakkyawan haɓakar lantarki

--- High thermal watsin

--- costananan kayan albarkatu

--- Babban daidaito da kwanciyar hankali

--- Kyakkyawan damar bango na bakin ciki

- Ability don siffar sanyi, wanda ke sauƙin shiga

--- Kyakkyawan halaye na ƙarewa

--- Mahimmancin juriya lalata --- cikakken sake sakewa

2.Alloy Alloy Alamu:

--- Babban yanayin zafi

--- Fuskantar lalata lalata

--- Mara nauyi

--- Kyakkyawan ƙarfi da taurin rai

--- Kyakkyawan tauri da ƙarfin ƙarfi-zuwa-nauyi

--- Kyakkyawan kayan kariya na EMI da RFI

--- Kyakkyawan haɓakar yanayin zafi

--- Haɗawar wutar lantarki

--- Kyakkyawan halaye

--- cikakken sake sakewa

3. Siffofin Gano Magnesium:

--- Babban haɓaka; lantarki, kuma thermal

--- Yana jure yanayin zafi mai aiki

--- Babban daidaito da kwanciyar hankali

--- thinwarewar bangon sirara mai ban mamaki

--- Kyakkyawan juriya lalata lalata

--- Kyakkyawan halaye

--- cikakken sake sakewa

1 Tsarin 'Yan Wasa Masu Zafin Hotuna

-Akin zafin mutu mai zafi, wani lokacin ana kiran sa goo goo goo gooseneck, shine mafi mashahuri daga cikin matakan simintin gyare-gyare biyu. A wannan aikin, dakin silinda na allurar allurar an nitsar da shi cikin narkakken wankin ƙarfe. Tsarin ciyarwar karafa ya zana narkakken karfe cikin ramin mutu.

Yayin da nutsuwa kai tsaye a cikin narkakken wanka yana ba da izinin allura mai saurin aiki da sauƙi, hakan kuma yana haifar da ƙara saurin lalata. Saboda wannan gaskiyar, aikin simintin mutu mai ɗumi-ɗumi ya fi dacewa da aikace-aikacen da ke amfani da karafa tare da ƙananan wuraren narkewa da ruwa mai ƙarfi. Kyakkyawan karafa don tsarin zafin mutu na ɗakin ɗumi sun haɗa da gubar, magnesium, zinc da jan ƙarfe.

2 Tsarin Cold-Chamber Mutu Wasa

The sanyi-jam'iyya mutu simintin tsari ne sosai kama da zafi-jam'iyya mutu simintin. Tare da ƙirar da ke mai da hankali kan rage ƙarancin na'ura maimakon ƙwarewar samarwa, narkewar ƙarfe ta atomatik- ko hannunta a cikin tsarin allura. Wannan yana kawar da wajibcin aikin allurar don nitsewa a cikin narkakken wankin ƙarfe.

Don aikace-aikacen da suka fi lalacewa don ƙirar nutsewa da simintin mutu-ɗumi mai zafi, tsarin ɗakunan sanyi zai iya zama kyakkyawan madadin. Wadannan aikace-aikacen sun hada da simintin karafa tare da yanayin zafi mai narkewa, kamar su gishirin aluminum da allo.

3 Lowarfin Diearfin Diearfin Mutuwar Matasa

Castaramin mataccen mataccen tsari tsari ne mafi dacewa da kayan haɗin aluminum waɗanda suke da daidaito a kusa da wata juyawa. Misali, ƙafafun ababen hawa, alal misali, galibi ana ƙirƙira su ne ta hanyar jefa diean matsi mai ƙarfi. A cikin irin wannan tsari, molin yana tsaye sama da narkakken wanka na ƙarfe kuma an haɗa shi ta bututun haɗari. Lokacin da aka matsa ɗakin (yawanci tsakanin 20 da 100kPa), ana jan ƙarfen zuwa sama da cikin sifar. Kawar da feeders daga wannan irin mutu simintin tsari kai da babban simintin da ake samu.

4 A injin Mutu Gyare Tsari

Vacuum matsin simintin gyaran kafa (VPC) sabon abu ne sabon tsarin jefa 'yan wasa wanda ke ba da ingantaccen ƙarfi da ƙananan porosity. Wannan tsari yayi kama da 'yar simintin mutu-matsin lamba, sai dai wuraren da aka yi simintin gyaran simintin gyare-gyaren da narkakken karfe mai narkewa ana juyawa. Chamberakin silinda na iya zama wuri, wanda ke tilasta narkakken ƙarfe zuwa ramin maƙerin. Wannan zane yana rage tashin hankali kuma yana iyakance adadin abubuwan shigar gas. Injin mutu simintin yana da fa'ida musamman a aikace-aikacen da aka ƙaddara don maganin zafin bayan bayan simintin gyaran fuska.

5 Matsi Matattarar ingarfin Mutuwar

Createdirƙirar ƙwanƙwasa an ƙirƙira shi azaman aiki mai aiki don simintin ƙarfe da gami da ƙananan ruwa. A wannan tsarin, narkakken karfen ya cika budadin budewa, wanda sai ya matse a rufe, ya tilasta karfan din a cikin sassan da ke rarar kayan aikin. Aikin yin simintin gyaran kafa yana samarda samfuran kayan masarufi kuma tsari ne wanda yake dacewa da maganin zafin rana mai zuwa. Ana aiwatar da aikin sau da yawa tare da narkakken aluminum, kuma ana amfani dashi a aikace-aikacen da ke kira don ƙarfafa fiber.

6 Semi-Solid Mutu 'yar Wasa tsari

Semi-m mutu simintin gyaran kafa, wani lokacin ana kiransa Thixoforming, wani tsari ne wanda ke ba da porosity da matsakaicin nauyi. Inji yana yankan kayan aiki a kananan karamomi, sannan yayi zafi. Da zarar karfe ya kai ga canzawar lokaci tsakanin daskararre da ruwa, wanda ya haifar da wani abu mai kama da jiki, sai rigar bindiga ta tilasta shi cikin ramin da yake, inda yake yin tauri. Fa'idar wannan ingantacciya ce. Ba ƙarfe da ba ƙarfe kamar gami na magnesium da gami na aluminium galibi ana amfani da shi tare da aikin jefa simintin ƙarfe mai ƙarfi.

7. Nau'in Mutu Fitar Tsari

Duk nau'ikan aiwatar da aikin simintin gyare-gyare an tsara su da manufa daya a zuciya-Fitar da wani abu ta amfani da narkakken karfe. Dogaro da nau'in narkakken ƙarfe, ɓangaren lissafi da kuma girman ɓangare, matakai daban-daban na yin simintin gyare-gyare na iya ba da sakamako mafi girma akan hanyoyin dabam. The biyu main iri mutu simintin matakai ne zafi-jam'iyya da kuma sanyi-jam'iyya mutu simintin. Bambancin kan waɗannan nau'ikan simintin mutuƙar mutu guda biyu sun haɗa da:

-Ananan matsa lamba jefa simintin gyaran kafa

Injin mutu simintin gyaran kafa

Matsi mutu simintin gyaran kafa

Semi-m mutu 'yan wasa

1 Hot matsa lamba jam'iyya mutu simintin inji

Dangane da tsari da fasalin ɗakin, ana iya raba shi zuwa siffofin kwance da na tsaye. Attachedunƙarar ƙarfe mai narkewa an haɗa ta da inji ta wurin matattarar ɗumi mai zafi, kuma an saka makamin piston na matsi na hawan ƙarfe da ke shigar da ƙirar a cikin dutsen. Wasu pressingan matattara masu ɗaukar zafi suna amfani da iska mai matse iska kai tsaye yin allurar hawan ƙarfe ta ƙarfe cikin sifa ba tare da injin piston ba.

Hot jam'iyya mutu simintin inji

The zafi latsa jam'iyya mutu simintin inji ne yafi amfani ga mutu-simintin gami da low narkewa batu, kamar tutiya, Magnesium da tin.

2 Cold matsa lamba jam'iyya mutu simintin inji

Narkewar karfe a waje da inji sannan a kara karfe mai ruwa a cikin dakin matsewa tare da cokali za'a iya raba shi zuwa dakin sanyi na tsaye wanda zai mutu da simintin gyaran sanyi da kuma dakin sanyi mai kwance a kwance kamar yadda shugabanci na motsin fiston na matsawa yake.

An cire karfe mai ruwa daga wutar da ke tsaye dakin daddare dakin sanyi wanda aka kashe shi kuma aka zuba shi a cikin dakin matsawa. Metalarfe naƙun ƙarfe ne ake matsawa cikin sifar ta fiskan matsewa, kuma wani ƙarin fishon ne yake tura ƙarin rarar.

Cold jam'iyya mutu simintin inji

Cold jam'iyya mutu simintin inji

A kwance sanyi jam'iyya mutu simintin inji ne guda da a tsaye daya, amma fistan motsi ne a kwance. Yawancin injunan 'yan simintin zamani masu mutuƙar kwance ne. Cold-jam'iyya mutu-simintin inji iya mutu-jefa high narkewa batu karafa ko sauƙi oxidized karafa, kamar aluminum, jan gami, da dai sauransu.

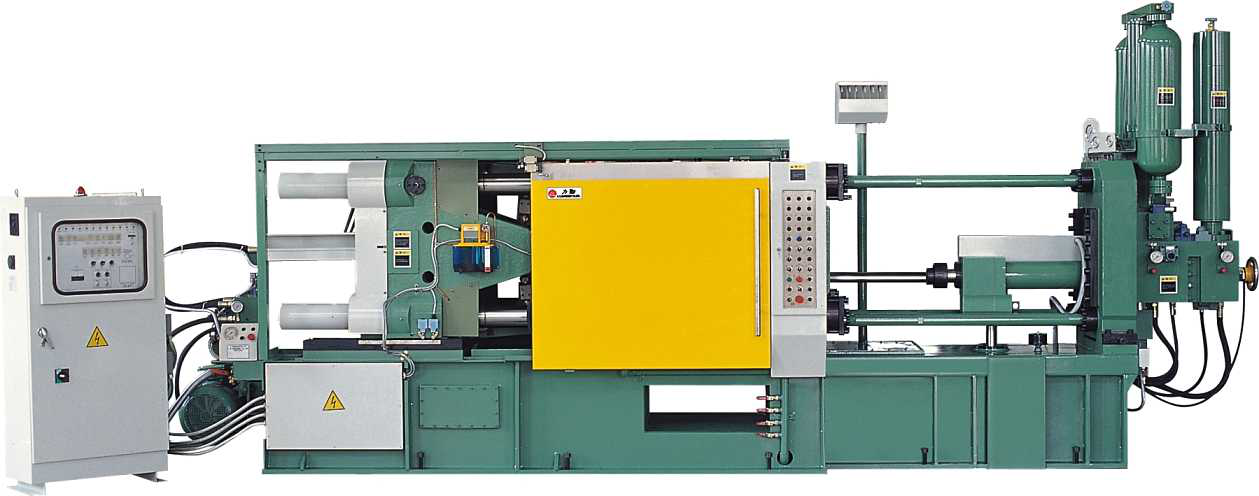

3.Die simintin inji.

Mutu 'yan wasa inji da ake amfani da matsa lamba simintin inji. Yana hada da iri biyu na zafi latsa jam'iyya mutu simintin inji da sanyi latsa jam'iyya mutu simintin inji. Yankin matse sanyi mai inji ya kasu kashi biyu: madaidaiciya da kwance. Jectedwanan da aka narkar da shi ana yin allurar shi a cikin sifar ta hanyar injin simintin mutu-ƙarkashin aikin matsin lamba don sanyaya da samarwa, kuma ana iya samun daskararrun ƙarfen bayan an buɗe sifar.

Hot jam'iyya mutu simintin inji

Cold jam'iyya mutu simintin inji

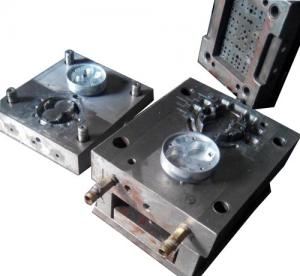

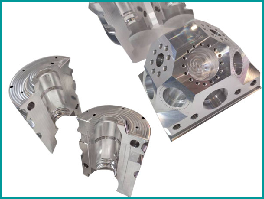

4.Die simintin gyare-gyare

A cikin wasu nau'ikan kayan kwalliya, yanayin aikin mutuwar 'yan wasa mutu ne mai tsananin kaifi. Mutu da simintin gyaran kafa shine sanya narkakken karfe mai cike da ramin buya a karkashin matsin lamba da babban gudu, da kuma tuntubar karfe mai zafi sau da yawa yayin aikin aiki. Saboda haka, mutu Fitar mold ake bukata don samun high thermal gajiya juriya, thermal watsin da kuma ci juriya, lalata juriya, tasiri taurin, ja taurin, mai kyau demoulding da sauransu. Saboda haka, saman magani fasaha na mutu simintin mutu bukatar high fasaha.

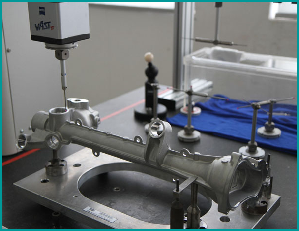

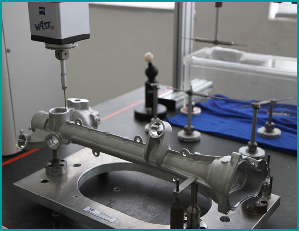

Mutu Fitar mold

5.Posting Processing da Gamawa don Mutu 'yan Wasa sassa

Muna ba da mafi yawan aikin aika post da sabis na kammalawa don sassan juzu'i daga zaɓaɓɓun abokanmu:

Ayyuka

Kayan aikin CNC - a tsaye, a kwance, juyawa, 5-axis

Rufin Foda

Shafin Liquid

EMI - Garkuwar RFI

Gwaninta - chrome, jan ƙarfe, zinc, nickel, tin, gold

Anodizing, Shafin lantarki, Chromating / Non-chromating

Maganin Heat, Passivation, Tumbling

Zane-zane

Tsarin Aikin Gida

Nuna siliki

Kushin Fitar

Dutsen dusar ƙanƙara

Meungiyar Injin Haske, gami da ingarma da abubuwan saka helicoil, O-ring, gasket

Yankan Laser da Sassakawa

Etching

Shafin lantarki & Nunin siliki