Alamar karfe

Short Bayani:

Stamping na karfe shine amfani da naushi da mutu don nakasa ko karaya da bakin ƙarfe, ƙarfe, aluminium, jan ƙarfe da sauran faranti da kayan ƙetare don cimma wani nau'i da girman tsari.

The stamping tsari za a iya raba cikin rabuwa tsari da kuma kafa tsari (ciki har da lankwasawa, zane da kuma kafa). Tsarin rabuwa shine raba ɓangaren sintiri da blank tare da wani layin kwane-kwane a cikin aikin hatimi, kuma ingancin ɓangaren da aka rabu na ɓangaren hatimi dole ne ya cika wasu buƙatu; Tsarin tsari shine sanya gurɓataccen lalacewar filastik a ƙarƙashin yanayin lalacewa, da canza shi zuwa samfurin samfurin da ake buƙata, sannan kuma ya cika buƙatun haƙuri da sauran fannoni.

* Dangane da yanayin zafin zafin, akwai hanyoyi biyu na sanya sanyi da kuma zafin zafi. Wannan ya dogara da ƙarfi, filastik, kauri, nakasassu digiri da damar kayan aiki na kayan, kuma asalin yanayin maganin zafi da yanayin sabis na ƙarshe na kayan ya kamata a yi la’akari da su. 1. Cold stamping karfe aiki a dakin da zazzabi, kullum zartar da kauri na kasa da 4mm blank. Yana da fa'idodi na babu dumama, babu fatarar oxide, kyakkyawan yanayin ƙasa, dacewar aiki da ƙarancin farashi. Rashin dacewar shine akwai wani sabon abu mai wahalar da aiki, wanda ke sanya karfan ya rasa damar kara nakasa. Kaurin blank din dai iri daya ne kuma ba a bukatar karce. 2. Hot stamping karfe yana mai tsanani zuwa wani yanayin kewayon zafin jiki. Abubuwan fa'idodi sune cewa zai iya kawar da damuwar cikin gida, kauce wa tauraruwar aiki, ƙara yawan filastik, rage juriya nakasa da rage ƙarfin amfani da kayan aiki

* Samfura kayayyakin

* Abubuwa uku masu mahimmanci na tsarin samarwa: mutu, latsa da ƙarfen ƙarfe

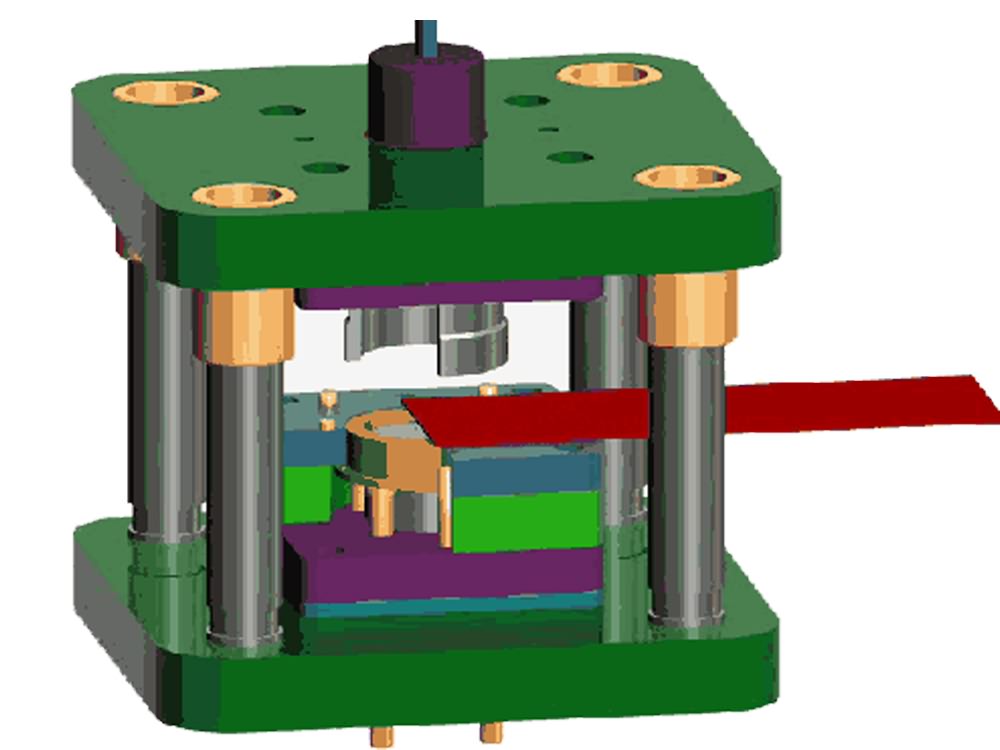

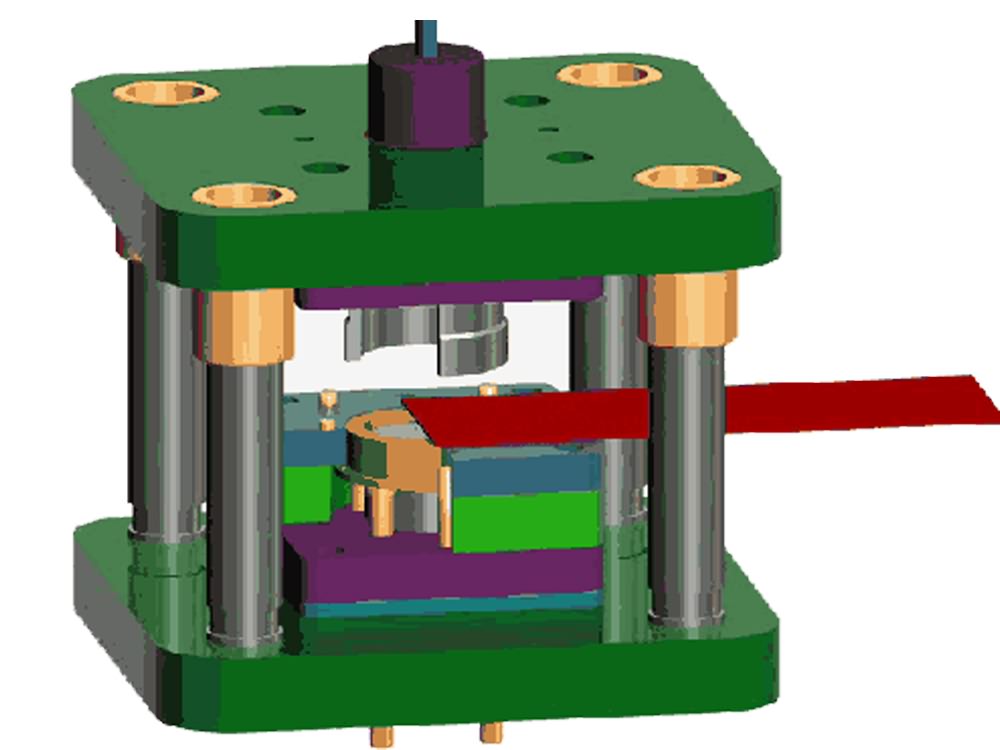

1. Punching Die Die shine mutuƙar mahimmanci a samar da samfuran samfuran. Akwai turmi iri uku ya mutu: sauƙin mutuwa, ci gaba da mutuwa da mahaɗan mutu.

Mutuwar Mutuwa mutuƙar mahimmanci ce ta samar da samfuran samfuran. Akwai turmi iri uku ya mutu: sauƙin mutuwa, ci gaba da mutuwa da mahaɗan mutu.

(1) Sauƙin mutuwa: mutuwa mai sauƙi mutuwa ce wacce kawai ke kammala aiki ɗaya a bugun jarida ɗaya. Ya dace da ƙaramin tsari na sassa masu fasali.

(2) Cigaba da mutuwa: a bugun ɗayan latsawa, mutuwar wacce ta kammala wasu ayyukan hatimi a sassa daban-daban na mutuwar a lokaci guda ana kiranta ci gaba mai mutuwa. Cigaba da mutuwa ya dace da ingantaccen aiki na atomatik.

(3) dieungiyar ta mutu: a cikin bugun jini, a cikin ɓangaren mutu don kammala ayyukan ɗimbin yawa a lokaci guda, wanda aka sani da mutuƙar haɗin gwiwa. Mahadi ya mutu ya dace da sassan hatimi tare da babban fitarwa da madaidaici.

2. Injin Punching

Stamping samar ne yafi ga farantin. Ta hanyar kayan kwalliya, na iya yin kwalliya, hudawa, kafawa, zane, kammalawa, banbancin kyau, tsarawa, sassan riveting da extrusion, da dai sauransu, ana amfani dasu a wurare daban-daban. Misali, muna amfani da mabudin, kwanduna, kofuna, kofuna, kwanoni, akwatunan komputa, harma da jiragen sama masu linzami Akwai kayan haɗi da yawa waɗanda za'a iya samar dasu tare da naushi ta hanyar abin moɗa. Akwai nau'ikan inji naushi.

(1) Injin wutar lantarki injin Inji naushi ya gyara bugun jini, daidaitaccen saurin da kuma rashin karfin aiki. Matsakaicin iyakar 180 sau / min.

(2) na'ura mai aiki da karfin ruwa

Naushin lantarki na iya daidaita bugun bugun jini ta hanyar bawul din lantarki don inganta yawan aiki. Mafi girman gudu zai iya kaiwa sau 1000 / min. Rashin dacewar shine yawan amfani da wutar lantarki, manyan buƙatu akan muhalli da nauyin aiki mai nauyi.

(3) latsa lambar lamba turret punch press

Amfani da servo motor don tuka kan, yawan aiki yana da ƙarfi, har zuwa sau 800 / min. Imumarancin amfani da ƙarfi, sauƙin kulawa da ƙarami. Saboda haka, an yi amfani da shi sosai.

Don bugun ƙarfe na ƙarfe na yau da kullun, yawancinsu suna amfani da naushin inji. Dangane da ruwa daban-daban da ake amfani da su a matatun mai, akwai na’urar samar da ruwa da kuma na lantarki. Mafi yawansu suna amfani da matattun ruwa, yayin da galibi ake amfani da su don manyan ko injina na musamman. Saboda fa'idodi masu fa'ida, ana amfani da huhun mashin da ƙari.

3.Hanƙarin kayan stamfa Kayan kayan sassa gabaɗaya farantin karfe ne. Abubuwan da aka zaɓa don ƙirar samfuri za su haɗu da aikin sabis na samfurin, kamar taurin kai, ƙarfi da iya sarrafawar samfurin. A gefe guda, ya kamata ya sadu da buƙatun filastik, yanayin ƙasa da kaurin aikin ƙira. Tsarin tsari na kayan ɗamara yakamata yayi la'akari da halaye na sifa, lankwasa radius, ramin sakawa, shiri, zurfin zane, da dai sauransu. Farantin da aka saba amfani dasu sune ƙananan ƙarfe na ƙarfe, bakin ƙarfe, aluminum, jan ƙarfe da gami da allo, waɗanda suke da filastik mai yawa da low nakasawa juriya, kuma sun dace da sanyi stamping. (1). Ferrous karafa: SPCC / SPCD / spce, SECC / SECD / sece, SGCC, sgld, Sus (2). Allon gami: al1050p, al1100p, al5020 (3). Gilashin tagulla: Pb phosphor tagulla, HBS mai ƙarfi tagulla (4). Cupro nickel gami

* Fasahar kula da farfajiyar sassan hatimi Bayan fara sarrafa karfen da fasalin sa, yana bukatar gyara fuskar karfen, da kawata farfajiyar, da kara canza yanayin kayan inji da na zahiri da na sinadarin karfe. Wannan tsari ana kiransa maganin karafa. Dalilin maganin karafan karfe ya kasu kashi hudu:

(1) Mai kyau

(2) Kariya

(3) keɓaɓɓen kayan ƙasa

(4) Inganta kayan aikin inji, kamar juriya da saɓo, man shafawa, da sauransu.

* Nau'in maganin farfajiyar lantarki (zinc, copper, nickel, chromium, gold, azurfa), electrostatic spraying, spray spray, electrophoresis, silk allo bugu, anodizing, blackening, passivation

* Sheet karfe stamping ne mai sauki a cimma babban ingancin aiki samar ta hanyar inji da kuma aiki da kai sauki don gane inji da kuma aiki da kai tare da babban samar da inganci; sassan hatimi suna da girma daidai da kyakkyawar musanyawa; saman yana da santsi da santsi, yawanci ba tare da inji ba. Ana amfani dashi ko'ina cikin motar, kayan aikin lantarki, kayan aiki, jirgin sama da sauran masana'antun masana'antu.

Mestech tana samar muku da kayan karfe da samfuran karfe. Idan kuna da wata buƙata ko buƙatar ƙarin sani, da fatan za a tuntube mu.