Samfurin filastik

Short Bayani:

Don samfuran filastik waɗanda ke buƙatar samar da sifa, yawanci muna yin jiki samfurin filastikdon tabbatar da tsarinta. Yana nufin samfurin aiki ɗaya ko da yawa waɗanda aka yi bisa ga zanen bayyanar samfur ko zane-zane ba tare da buɗe sifa don bincika ƙimar bayyanar ko tsari ba. Samfurin filastik a wurare daban-daban kuma ana kiranta da samfurin filastik, samfuri, mackup.

Samfurin filastik wata hanya ce mai mahimmanci don kimanta ƙirar samfuri da kayayyakin nunawa. Ya dogara ne akan zane-zanen zane, ta amfani da kayan aiki na inji ko resin laser warkewa ko tsarin haɗawa don samar da samfuran don kimanta zane da nuni. Lokacin da muke tsara sabon samfuri, yawanci ana yin samfuran ne bisa ga samfurin samfurin ko zane-zanen tsari don duba bayyani ko tsarin hankali na samfuran aiki. Yin samfurin shine ɗayan hanyoyi mafi inganci don tabbatar da ƙirar samfuri da rage haɗarin masana'antu.

Tare da nufin samar da ingantacciyar hanya don ƙera samfurinka da kayan aikin ka, injiniyoyin ƙirar mu suna nan don samar maka da ƙirar sabis don ƙera kaya don tabbatar da samfuran ka koyaushe sun dace da masana'antar samfurin roba. Ta hanyar cikakken bincike da takamaiman zaɓi na kayan abu, zamu iya ƙarfafa ƙarfin aikinku kuma mu ba da sabis na samfuri mai sauri don yaba zane- wannan yana ba da wadatattun dama don gwajin aiki wanda zai haskaka duk canje-canjen da ake buƙata waɗanda ake buƙatar yin su don ƙira don dacewa da bukatun kasuwancin ku. Wannan yana tabbatar da cewa batutuwan ƙirar samfuran ba su shiga matakin biyo baya na ƙirar moɗa, don kauce wa gazawar marigayi da ɓarnatar da tsada mai yawa. Don samfuran masana'antu masu girma, ko hadaddun kayayyakin lantarki, kayan lantarki, motoci, kayan aikin likitanci, burushin goge baki, kofukan ruwa da sauran buƙatun yau da kullun masu sauƙi, a cikin matakin ƙirar samfur, samfurin samfuri ya kamata a sanya don kimantawa da tabbatar da ƙwarewar fasaha, fasaha da al'amuran kasuwa, kuma koyaushe inganta ƙirar ingantawa. Samu sakamako mafi kyau.

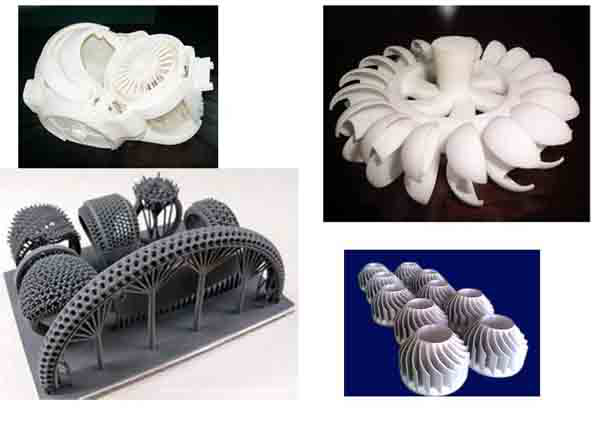

Iri da kuma amfani da samfurorin roba

1. Bayyanar samfur: A farkon sabon matakin ƙirar samfuran, sanya samfurin sifa don kimantawa da haɓaka fasalin fasalin samfurin daban, kuma zaɓi mafi kyawun tsari mai kayatarwa ga abokan ciniki.

2. Tsarin samfuri:Bayan samfurin tsarin ƙirar an kammala shi, yawanci ana yin samfurin ne bisa ga zanen ƙirar zane kafin ƙirar ƙira. Mai zanen yana duba samfurin ƙirar tsari don gano abin da ya ɓata cikin zane a gaba, da inganta da inganta ƙirar, don kauce wa haɗarin masana'antar.

3. Samfurin aiki: Dangane da bukatun kwastomomi ko buƙatun haɓaka kasuwa, ana gabatar da samfurin zuwa kasuwa da abokan ciniki kafin ƙirar ta yi ko kuma ba a kammala fasalin ba.

Bayyanar / Samfurin tsari

Samfurin aiki

Samfurin tsari

Akwai manyan fasaha guda biyar don yin samfurorin filastik kamar haka

CNC machining samfura filastik

1. CNC machining:Samfurin samfurin yafi samar dashi ta cibiyar yankan. Dangane da zanen zane na kayan, ana cire kayan aikin daga daskararren filastik ta hanyar yankan kayan aiki akan kayan mashin yankan, kuma sassan da suka dace da girma da sifa an samu. Bayan aikin CNC, ana buƙatar aikin sarrafa kai tsaye.

--- Amfani: ana iya yin sassan abubuwa daban-daban bisa ga buƙata; sassan da aka sanya suna da madaidaicin daidaito, ƙarfi kuma babu murdiya; mai sauƙin samun ingancin ƙasa mai sauƙi, mai sauƙin fenti, zaɓin lantarki da kuma buga allo. Ya dace da samfurori tare da daidaitawar taro, sassan motsi, manyan ɓangarori, sassa tare da bayyanar ado, da injunan aiki. Lokacin aikawa kwana 7-8 ne. Ya dace da yin samfuran bayyanar, samfurin aiki da samfurin tsari.

--- Kayan aiki: ABS, PC, POM, PMMA, nailan, da dai sauransu.

--- Rashin Amfani: Rashin dacewar shine bukatar wani adadi na sarrafa kayan hannu, tsada mai yawa. Thearin rikitarwa tsarin, mafi girman farashin.

2. SLAko Stereolithography Prototyping - Fasahar SLA ta ƙarfafa ɗayan ɗayan ta hanyar ɗaukar hoto ta laser. Ta hanyar katakon laser ta ultraviolet, gwargwadon tsararren sashin asalin layin, yana warkarwa aya bayan aya, daga aya zuwa layi, daga layi zuwa farfajiya, ta hanyar motsin dagawar dandamali, an kammala buga takardu masu girma uku ta hanyar ajiye Layer ta Layer . An cire samfurin daga tanki kuma an daidaita shi ƙarƙashin fitilar ultraviolet. Dogaro da mawuyacin hali, kwanan watan isarwa zai iya gajarta kamar kwana 2-3.

SLA samfurin roba

3. SLSko zaɓin zaban laser. Wannan ya haɗa da abubuwan haɗin gini daga bayanan 3D ta amfani da hoda da lasers. Za a iya amfani da ƙirar allurar ƙira don samar da wasu ayyuka, gami da abubuwan haɗin "ƙugiya mai motsi". Kwanan watan isarwa na iya zama kwanaki 2-3, ya dogara da mawuyacin hali. A yayin aiwatar da sinadarin SLS, zafin zafin abu (ko abin ɗaure shi) ya isa wurin narkewa, kuma ba zai iya gudana da kyau ba kuma ya cika rata tsakanin ƙwayoyin foda. Sabili da haka, farfajiyar sashi yana da sako-sako kuma yana da tsauri.

--- Ab Adbuwan amfãni: strengtharfi mai kyau, ba mai sauƙin canzawa ba, juriya mai tasiri, na iya tsayayya da nauyi da kuma adadin inji. Mai sauƙin ɗaurewa. Juriya lalata. Ya dace da yin samfurin tsari.

--- Kayan abu: Yin amfani da foda nailan, polycarbonate foda, acrylic polymer foda, polyethylene foda, nailan foda hade da 50% gilashin beads, elastomer polymer foda, yumbu ko karfe da m foda da sauran kayan, kwatanta kwatankwacinsu.

--- Rashin amfani: rashin daidaitattun girma da ingancin ƙasa. An yi amfani dashi don samfurin tsari wanda ba a buƙatar ƙimar bayyananniya.

4. Samfurin vacuum(Vacuum Filling) Haɓaka isaƙƙarfa hanya ce ta yin samfuran ƙananan tsari. Yana amfani da samfurin asali (samfurin CNC ko samfurin SLA) don yin silar silica a cikin wuri, kuma yana amfani da kayan PU don zubawa a cikin injin, don haɗawa iri ɗaya irin na samfurin farko, wanda ya fi ƙarfin juriya zafi, ƙarfi da taurin fiye da asalin samfur. Idan abokan ciniki suna buƙatar saiti da yawa ko dama, ya dace don amfani da wannan hanyar, wanda ke rage ƙimar sosai.. Kayan aiki na iya samar da nau'ikan kayan kwaikwaiyo don cimma wasu kaddarorin sassan gyaran allura. Kwanan watan isarwa na iya zama kwanaki 7-10, ya danganta da sarkakiya.

--- Ab Adbuwan amfãni: Ya zama dole a yi amfani da CNC ko SLA don yin samfurin asali, wanda ya dace da saiti da yawa zuwa ɗimbin saiti na ƙananan samfuran samfuran. Matsayin kwanciyar hankali, ƙarfi da tauri sun fi samfurin SLA girma, kusa da samfurin CNC. Ya dace da yin samfuran bayyanar. Samfuran aiki da samfurin tsari.

--- Kayan abu: Ana amfani da resin PU gabaɗaya, amma kuma na iya samar da nau'ikan kayan kwaikwaiyo.

--- Hasara: Bai dace da sassa masu fasali mai rikitarwa ba. Farashin yana ƙasa da na samfurin CNC.

5. GASKIYA (Reaction Allura Molding) kuma shine amfani da asalin samfuri (samfurin CNC ko samfurin SLA) wanda aka yi da silica gel mold, ruwan allurar polyurethane PU mai ruwa biyu ana shigar dashi cikin saurin tsinkaya a yanayin zafin jiki da kuma yanayin matsin lamba, warkewa da post -aiwatarwa don samo samfuran filastik da ake buƙata.

--- Abvantbuwan amfãni: Ana amfani da shi don ƙarami tsari na yin amfani da bangarori masu sauƙi da girma da kuma samar da samfuran kaurin bango mai kauri da mara daidaituwa. Yana da fa'idodi na ingantaccen aiki, gajeren zagaye na samarwa, tsari mai sauƙi da arha mai tsada.- Kayan aiki: Pure polyurethane mai hade biyu.

--- Hasara: Kayan da akayi amfani dasu guda daya ne.

Samfurin saman magani: goge, zanen, siliki bugu, gilding, electroplating.

Kowane tsari na saurin samfuri na iya ba da nau'ikan abubuwan gama-gari da fasahar zane-zane, don ƙirƙirar ƙirar ƙwararru. A wannan matakin, injiniyoyinmu na iya ba da shawarar ƙarin zaɓuɓɓukan kayan aikin samfuri don cimma samfuran aiki da ƙoshin lafiya. A matsayin sabis na tsayawa guda, muna samar muku da jerin sabis, kamar ƙirar samfur, samfuri, sarrafa ƙira da gyaran allura, ƙera kayan aiki, da haɗuwar samfur. Yana ɗayan ɗawainiya don samar muku da samfurin samfurin filastik da ɓangarorin ƙarfe. A cikin zagayen haɓaka samfuran ku, tare da cikakken taimakon mu, zamu iya tabbatar da cewa samfuran ku sun shiga kasuwa cikin cikakken aiki da farashi mai sauƙi.

Proimar samfur wani muhimmin ɓangare ne na ƙirar samfura. Mestech kuma yana ba da ƙirar samfuri, kayan aiki na kayan ƙira, gyaran allurar roba da sabis ɗin taron samfu don ƙarin tallafawa tsarin masana'antar ku.