Sassa sassa

Short Bayani:

Sassa sassasune asalin kayan aiki na kayan inji da kayan aiki daban-daban. Kayan aiki da aikin da yake amfani dasu sun haɗu da matakin mafi girman ƙirar injiniya na yanzu, kayan aiki, narkewa, injuna, kayan lantarki, sarrafa masana'antu da sauran fannoni.

Tare da ci gaban fasaha, daidaitattun sassa da kayan aiki suna da muhimmiyar rawa a masana'antar masana'antu ta zamani. MESTECH ya kasance yana samarwa kwastomomi madaidaicin aiki na kayan karafa da na wadanda ba na karfe ba tsawon shekaru.

Menene matsayin rawar ƙarfe masu daidaito a cikin masana'antar zamani?

Kayan aikin inji shine "Injin uwar masana'antu” . Kusan dukkanin masana'antun kayan aikin injiniya basa rabuwa da aikin injiniya. Tare da ci gaba da ci gaba da fasaha da kayan aiki, akwai babbar buƙata don daidaitattun sassa, kamar jirgin sama, sararin samaniya, mota, likita, likitancin hankali da ƙirar guntu, duk waɗannan ba sa rabuwa da goyon bayan sassan daidaito. Yadda za a cimma ingantaccen aiki da ƙananan farashi na daidaitattun sassa lamari ne na masana'antun masana'antu.

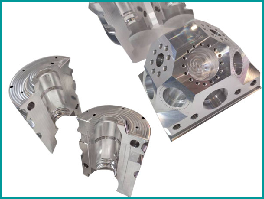

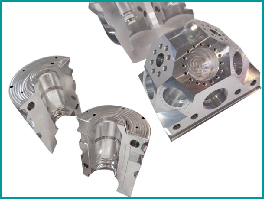

Karfe tushe

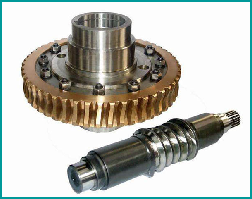

Kayan tsutsa

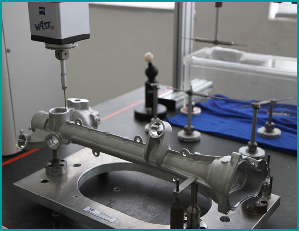

High daidaici sassa

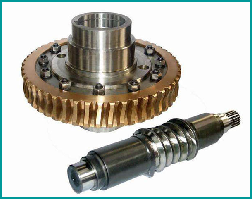

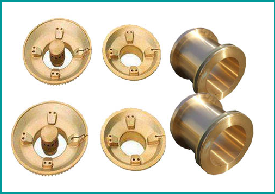

Sassan tagulla

Nawa nau'ikan aikin sarrafa abubuwa ka sani?

Daidaitaccen aikin inji tsari ne na canza girma ko aikin abin aiki ta hanyar injin sarrafawa. Dangane da yanayin yanayin zafin aikin da ake sarrafa shi, ana iya raba shi zuwa sarrafa sanyi, sarrafa zafi da aiki na musamman. Gabaɗaya ana sarrafa shi a yanayin zafin ɗakin kuma baya haifar da canje-canje na sinadarai ko na zahiri na kayan aikin. Ana kiran shi aiki mai sanyi. Gabaɗaya, aiki a ƙasa ko ƙarancin zafin jiki na yau da kullun zai haifar da canje-canje na sinadarai ko na zahiri na abin ɗora hannu, wanda ake kira sarrafawar zafin jiki. Za'a iya rarraba aikin sanyi zuwa yankan da sarrafa matsa lamba bisa ga bambancin hanyoyin sarrafawa. Heat magani, ƙirƙira, simintin gyare-gyare da waldi ne na kowa a cikin zafi aiki. Yanke daidaito shine sau da yawa hanyar haɗin aiki na ƙarshe don tabbatar da daidaito na ɓangarori, kuma shima mahaɗi ne tare da mafi girman aiki, ɗaukar sama da 60% na sarrafa kayan aikin inji.

Menene ainihin Yankan Injin?

Yankan Inji shine babbar hanyar sarrafa kayan injiniya, tana nufin tsarin cire kayan ta hanyar madaidaicin inji.

Daidaitaccen yankan inji shine nau'in injin sarrafawa tare da madaidaicin daidaito. Akwai manyan hanyoyi guda biyu don aiwatar da daidaitattun kayan aiki na sassa:

(1) isaya shine amfani da kayan aiki na madaidaici don aiwatar da sassan madaidaici, kamar haɗin mai haɗawa mai haɗawa, injin niƙa, ƙyamar tsutsa, injin niƙa, injin nika, ƙirar waje mai ƙyama, madaidaicin madaidaiciyar hob, babban -precision thread lathe, da dai sauransu.Wadannan kayan aikin injin sune kayan aikin musamman na musamman, wadanda aka fi amfani dasu musamman wajen sarrafa wani bangare na bangarori, kamar su giya, turbines, dunƙule, kayan aikin yankan kai, madaidaiciyar hanyar watsawa da akwatin injin, da sauransu Wadannan kayan aikin inji suna da inganci sosai kuma suna aiki daidai da aiki na musamman.

(2) Na biyu shine amfani da fasahar biyan diyya don inganta daidaitaccen aiki na ɓangarori. Babban kayan aikin sarrafa kayan masarufi sune CNC milling machine, CNC lathe, CNC grinder, CNC boring da milling machine, da kuma cibiyar machining compound.

Kayan aikin inji na CNC galibi sune kayan aikin injina gabaɗaya, saboda amfani da fasahar shirye-shiryen komputa, ana iya shirya su akan sarrafa kwaikwaiyo da lalatawa, yana da dacewa mai kyau da daidaitawa, dace da fasali mai rikitarwa, nau'ikan sarrafa abubuwa iri-iri. Kayan aikin CNC suna da tsada, amma zasu iya fahimtar aikin sarrafa kai, kuma suna da ingantaccen maimaitaccen aiki da ingancin aiki.

Yaya za a zabi kayan aikin sarrafawa masu dacewa?

Tare da ci gaba da fasahar sarrafa kwamfuta, ana haɗa kayan aikin inji tare da tsarin CNC, don fahimtar aikin sarrafa kai, kauce wa kurakuran aiki na hannu, da haɓaka daidaitaccen aiki da kwanciyar hankali. Sabili da haka, ana amfani da kayan aikin inji na CNC a fagen masana'antun sassa masu daidaito.

(1) daidaitaccen aikin CNC na ƙarfe mai ƙarancin ƙarfe yana da girma, tare da ingancin aiki mai inganci;

(2) Zai iya aiwatar da haɗin kai da yawa tare da aiwatar da sassa tare da sifofin rashin tsari.

(3) Lokacin da aka canza sassan CNC na kayan aikin kirki, kawai shirin NC yana buƙatar canzawa don adana lokacin shirye-shiryen samarwa.

(4) Kayan aikin mashin din kanta yana da cikakkiyar daidaito da tsauri, kuma zai iya zaɓar adadin aiki mai fa'ida, kuma ƙimar fitarwa tana da yawa (gaba ɗaya sau 3 zuwa 5 na na kayan aikin injiniya).

(5) Kayan aikin injin suna sarrafa kansu sosai kuma suna iya rage ƙarfin aiki.

Cikakken aiki na CNC ta amfani da gajeren kayan aikin yankan shine babban fasalin sassan kayan aikin lafiya. Gajerun yankan kaya na iya rage karkatar da kayan aiki sosai, sa'annan a sami kyakkyawan yanayin farfajiya, kauce wa sake yin aiki, rage amfani da sandunan waldi, da kuma gajarda lokacin sarrafa EDM. Yayin da ake la'akari da aikin kera axis guda biyar, ya zama dole ayi la’akari da ka’idar amfani da kayan aiki guda biyar-biyar din: don kammala aikin gaba dayan kayan aiki tare da mafi kankantar kayan abu gwargwadon iko, amma kuma don rage shirye-shirye, matsewa da kuma sarrafa lokaci. don samun cikakkiyar ingancin farfajiya.

Yadda ake kirkirar fasahar sarrafawa?

(1) Matattarar aiki. Don yanke mafi yawan alawus na sarrafawa na kowane farfajiyar sarrafawa da kuma samar da takamaiman ma'auni, babban mahimmin abin dubawa shine inganta ƙimar aiki gwargwadon iko.

(2) Matakin kammala Semi. Cire yuwuwar gazawar bayan aiki mai tsauri, shirya don ƙarewar bayyanar, buƙatar buƙatar isa daidaitaccen aikin sarrafawa, tabbatar da dacewar ƙarewa, da gama aikin farfajiyar farfajiyar tare.

(3) Matakan kammalawa A wannan matakin, an zaɓi saurin yankan ƙasa, ƙaramin abinci da zurfin yankan don cire alawus na ƙarewa wanda aikin da ya gabata ya bari don sanya bayyanar sassan su haɗu da bukatun fasaha na zane.

(4) Matakan aikin Ultrafine. Ana amfani dashi galibi don rage ƙimar yanayin farfajiya ko ƙarfafa bayyanar aiki. Ana amfani dashi galibi don aiki tare da manyan buƙatu na ƙarancin ƙasa (ra <0.32 um).

(5) Matattarar aiki mai kyau. Daidaitaccen aikin injiniya shine micron 0.1-0.01 kuma ƙimar yanayin farfajiyar RA ƙasa da micron 0.001. Babban hanyoyin sarrafawar sune: yankewa mai kyau, nika madubi, nika mai kyau da gogewa.

Yaya za a zabi kayan da suka dace don kayan aiki?

Daidaitaccen aiki, ba duk albarkatun kasa zasu iya aiwatar da aikin daidai ba, wasu kayan albarkatun suna da matukar wahala, sun wuce taurin sassan kayan sarrafawa, na iya durkushe sassan inji, don haka wadannan kayan kayan basu dace da aikin inji ba, sai dai in an yi shi ne da kayan albarkatu na musamman, ko yankan laser.

Za'a iya raba kayan albarkatun kasa zuwa gida biyu, kayan karafa da kuma wadanda ba karfe ba.

Game da kayan karafa na karfe, taurin tsattsar karfe ya fi girma, biye da baƙin ƙarfe, biye da jan ƙarfe da softer aluminum.

Aikin kayayyakin yumbu da robobi na aikin albarkatun kasa ne wadanda ba na karafa ba.

1. Da farko dai, sassan dole ne su sami wani mataki na taurin. Don wasu aikace-aikacen, mafi girman ƙarancin kayan aikin blank, mafi kyau. Iyakantacce ne kawai ga buƙatun taurin sassan kayan aikin. Kayan aikin da aka ƙera ba zai iya zama da wuya ba. Idan sun fi kayan aikin inji ƙarfi, ba za a iya sarrafa su ba.

2. Abu na biyu, kayan matsakaici ne a cikin tauri da taushi. Aƙalla matakin ɗaya na taurin ya fi na ɓangarorin injina. A lokaci guda, ya dogara da aikin na'urorin da aka sarrafa da kuma madaidaicin zaɓi na kayan don sassan inji.

A takaice, har yanzu akwai wasu bukatun don ingancin abu a cikin daidaitaccen inji, ba duk kayan da suka dace da sarrafawa ba, kamar su laushi ko kayan lefe masu wuya, na farko ba lallai bane don aiki, kuma na biyun baya iya aiwatarwa.

Mestech tana bawa kwastomomi ƙira da sarrafa kayan ƙarfe daidai. Idan kana bukatar karin bayani, sai a tuntube mu.