Magungunan allurar filastik

Short Bayani:

Injin roba na roba shine kayan aikin samar da samfuran roba, wanda galibi ake amfani dashi don samar da taro. Injection mold zai iya samar da cikakken tsari da madaidaicin girman kayan roba a cikin sauki da sauri.

Menene kyawon allurar filastik

Injin roba na roba(ingin mold) wani nau'in kayan aiki ne don samar da kayayyakin roba, sannan kuma kayan aiki ne don bawa samfuran roba cikakken tsari da girman su daidai. Allurar gyare-gyare wani nau'in hanyar sarrafawa ne wanda ake amfani dashi wajen samar da taro na wasu sassa masu rikitarwa. Musamman, ana sanya filastik da narkewar zafi ya shiga cikin ramin ƙwanƙwasawa ta inji mai inji da ke allura a ƙarƙashin matsin lamba, sa'annan a sanyaya kuma a ƙarfafa shi don samun samfuran da aka ƙera.

Abubuwan halaye na kayan ƙira

1. Injection mold zai iya samar da sassan filastik tare da tsari mai rikitarwa, girman daidai da kuma ingancin ciki mai kyau a lokaci guda.

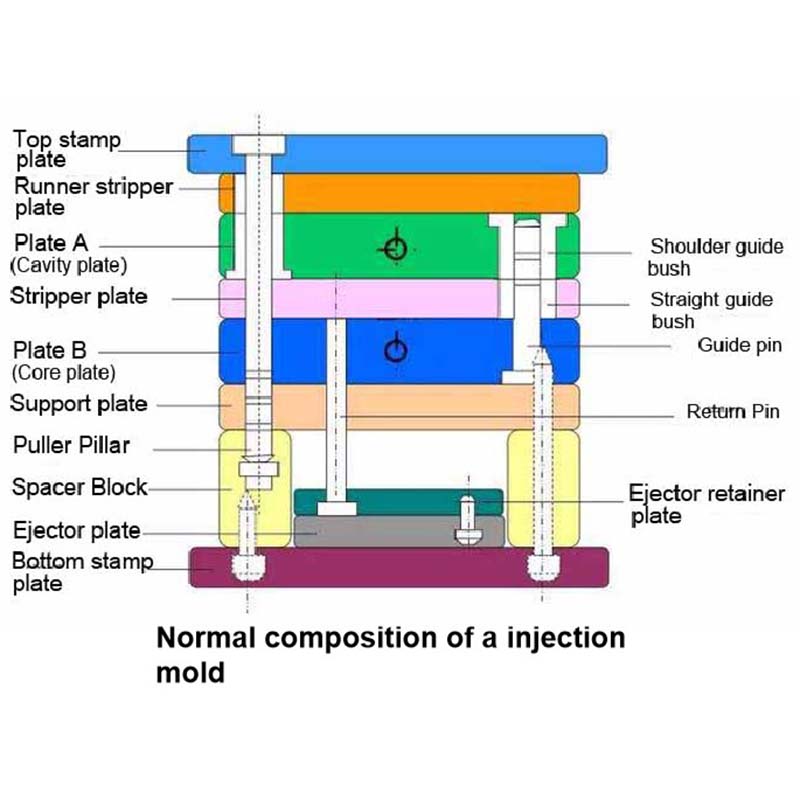

2.Kodayake tsarin molastik na roba na iya banbanta sosai saboda nau'ikan da aikin robobi, fasali da tsarin kayayyakin roba da nau'in injin allura, tsarin asali iri daya ne. A mould ne yafi hada da pouring tsarin, zazzabi kayyade tsarin, forming sassa da kuma tsarin sassa. Tsarin zubewa da sassan gyare-gyare sune sassan da suke cikin ma'amala kai tsaye tare da robobi kuma suna canzawa tare da robobi da samfuran. Su ne mafi rikitarwa da canza sassa a cikin filastik filastik, wanda bukatar mafi girma aiki gama da daidaici.

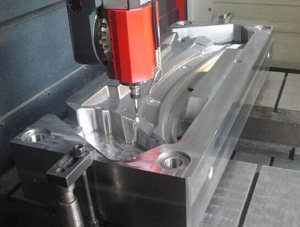

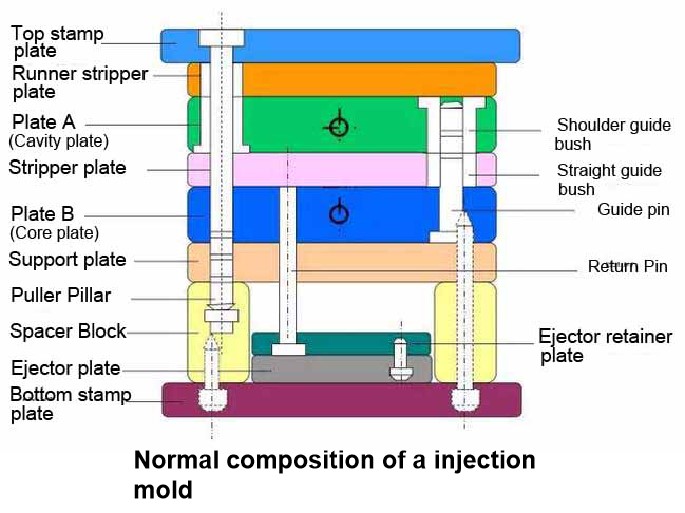

Haɗakar ƙwayoyin allura

Moldunƙarar allurar an haɗa ta da wani motsi mai motsi da kuma tsayayyen abin gyara. An shigar da mould mai motsawa akan samfuri mai motsi na injin gyaran allurar, kuma an sanya tsayayyen abin gyara akan tsayayyen samfuri na injin inki. Yayin da ake yin allurar allurar, mould mould da kafaffen mould suna rufe don samar da tsarin zubowa da kuma ramin maƙerin. Lokacin da aka buɗe nau'ikan, za a raba mould ɗin da kuma tsayayyen mai ɗaukar don fitar da kayayyakin roba. Don rage nauyin aiki na ƙirar ƙira da ƙera masana'antu, yawancin allurar ƙira suna amfani da madaidaicin ƙirar tushe.

Nau'in siffofi bisa ga halaye masu amfani

(1) Hoton mai gudu mai zafi

Tare da taimakon na'urar dumama jiki, robobi a cikin tsarin zubowa ba zasuyi karfi ba kuma baza'a lalata su da kayan ba, saboda haka ana kiran shi mai gudu mara gudu. Abvantbuwan amfãni: 1) Babu sharar 2) na iya rage matsi na allura, zai iya amfani da mol-caple molds 3) na iya rage zagaye na gyare-gyaren 4) inganta ingancin samfuran da suka dace da halaye masu saurin gudu mai gudu: 5) kewayon filastik mai narkewa mai fadi yana da fadi. Yana da ruwa mai kyau a ƙarancin zafin jiki da kyau kwanciyar hankali na thermal a babban zafin jiki. 6) Yana da hankali ga matsa lamba kuma baya gudana ba tare da matsi ba, amma yana iya guduwa lokacin da aka sanya matsa lamba. 7) Kyakkyawan takamaiman zafi, don yin sanyi da sauri a cikin mutuwar. Robobin robobi da ake dasu don masu gudu masu zafi sune PE, ABS, POM, PC, HIPS, PS. Akwai masu gudu masu zafi iri iri guda: 1) yanayin mai gudu dumama 2) yanayin mai gudu adiabatic.

(2) Hardanƙara mai wuya

Farantin karfe da aka yi amfani da shi a cikin mutuƙar ciki yana buƙatar magani mai zafi bayan sayayya, kamar ƙwanƙwasawa da ƙwanƙwasawa, don biyan bukatun amfani. Ana kiran wannan nau'in ingin mai tsananin wuya. Misali, cikin ciki ya ɗauki ƙarfen H13, ƙarfe 420 da ƙarfe S7.

(3) kyawon tsayi (a ƙasa 44HRC)

Steelarfan da aka yi amfani da shi a cikin mould na ciki na iya biyan buƙatun amfani ba tare da magani mai zafi ba bayan sayan. Irin wannan allura ana kiranta m mold. Idan mutuƙar ciki an yi ta da ƙarfe P20, ƙarfe na ƙarfe, ƙarfe 420, NAK80, aluminum da beryllium jan ƙarfe.

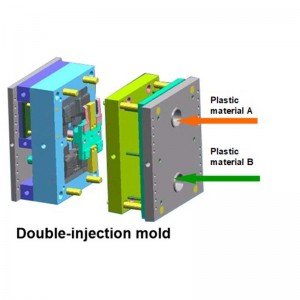

(4) Abubuwan da ake yin allura da su sau biyu

Maƙalar allurar rigakafi sau biyu wani nau'i ne wanda za'a sanya kayan roba biyu a kan inji mai inji iri ɗaya kuma a sarrafa su sau biyu, amma ana fitar da samfurin sau ɗaya kawai. Gabaɗaya, ana kiran wannan aikin gyare-gyaren abubuwa guda biyu, wanda yawanci ana kammala shi ta hanyar ƙirar mahaɗa kuma yana buƙatar inji mai ɗauke da allura ta harbi biyu

(5) Gwanin allura tare da adon in-mold & lakabin cikin in-mold

Injectionididdigar allurar filastik keɓaɓɓu ta hanyar tsarin wasan kwaikwayo

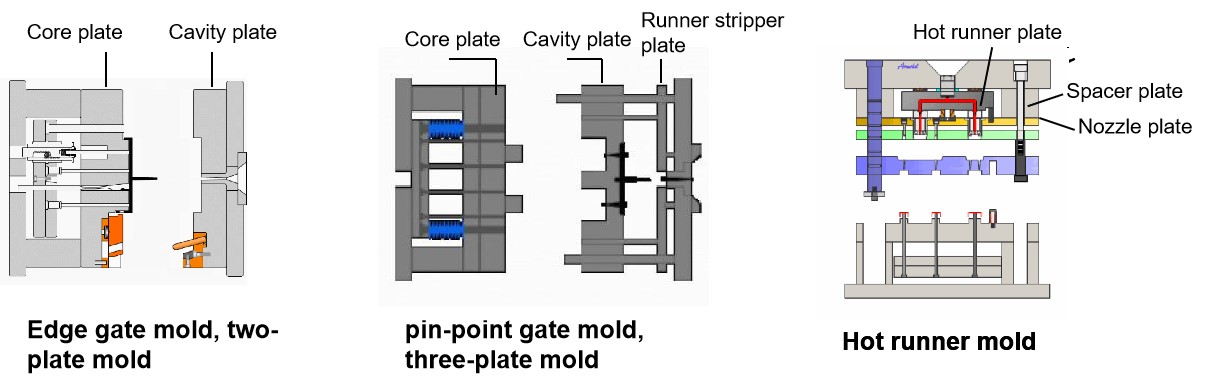

Za'a iya raba sifofin filastik zuwa gida uku bisa ga nau'ikan tsarin wasan kwaikwayo.

(1) Edge ƙofar mold (farantin farantin karfe biyu): Mai gudu da ƙofar ana demoulded tare da samfurin a kan rabuwa line. Tsarin shi ne mafi sauki, mai sauƙin aiwatarwa, kuma farashin yana da ƙasa. Saboda haka, yawancin mutane suna amfani da babban bututun ƙarfe don aiki. Tsarin sifar filastik ya kasu kashi biyu: dynamicarfafa tsayayye da tsayayyen abin gyara. Theangaren motsi na inji mai allura sashi ne mai motsi (mafi akasarin gefen fitarwa), kuma rashin aiki a ƙarshen fitowar mashin ɗin allurar ana kiranta gyaran ƙira. Saboda tsayayyen ɓangaren babban bututun ƙarfe yawanci an haɗa shi da faranti na ƙarfe biyu, ana kuma kiransa ƙirar kwano biyu. Farantin farantin karfe biyu shine mafi sauƙin tsari na manyan bututun ƙarfe.

(2) Maɓallin ƙofar mai nunin Pin (mai farantin farantin uku): mai gudu da ƙofar ba sa kan layin rabuwar, gabaɗaya kai tsaye kan samfurin, don haka ya fi rikitarwa don ƙirƙirar rukuni na layin raba hanci, da wahalar aiwatarwa . Gabaɗaya ana zaɓar tsarin ƙoshin lafiya bisa ga buƙatun samfurin. Kafaffen ɓangaren kyakkyawan bututun molg gabaɗaya ya ƙunshi faranti na ƙarfe uku, saboda haka ana kuma kiransa "ƙirar kwano uku" don irin wannan tsarin mutuƙar. Gilashin farantin kafa uku shine tsari mafi sauƙi na kyakkyawan bututun ƙarfe.

(3) Hot runner mold: Tsarin wannan nau'in mutuƙar daidai yake da na kyakkyawan bututun ƙarfe. Babban bambanci shine cewa mai gudu yana cikin ɗaya ko fiye da faranti mai gudu mai zafi da masu shayar zafi tare da zafin jiki na yau da kullun. Babu lalata kayan abu mai sanyi kuma mai gudu da ƙofar suna kan samfurin. Sabili da haka, mai gudu ba ya buƙatar lalatawa. Wannan tsarin ana kiransa da nozzle system, wanda zai iya adana albarkatun ƙasa kuma ya dace. Dangane da kayan tsada da tsada mafi tsada da buƙatu mafi girma don samfuran, yana da wuyar tsarawa da aiwatarwa, kuma farashin mutu da ƙirar suna da yawa. Tsarin mai gudu mai zafi, wanda aka fi sani da tsarin mai gudu mai zafi, yafi kunshi hannun riga mai zafi, farantin mai gudu mai zafi da akwatin lantarki mai sarrafa zafin jiki. Tsarin mu na yau da kullun mai zafi yana da nau'i biyu: mai tsaka-tsaka mai zafi da mai gudu mai yawa-maki. Pointofar ƙofa mai zafi guda ɗaya ita ce allurar narkakken roba kai tsaye zuwa cikin rami ta hannun hannun ƙofa mai zafi guda ɗaya, wanda ya dace da rami ɗaya da ƙyallen filastik guda ɗaya; pointofar mai zafi mai yawa shine raba narkakken abun zuwa kowane reshe atofar atofar ta faranti mai ƙofar zafi sannan shiga cikin ramin. Ya dace da rami ɗaya, abinci mai yawa da rami da yawa

Aikace-aikacen ƙwayoyin allurar filastik

Injection mold kayan aiki ne mai mahimmanci don samar da samfuran masana'antu daban-daban. Tare da saurin ci gaban masana'antar filastik da ingantawa da aikace-aikacen kayayyakin filastik a bangarorin masana'antu kamar jirgin sama, sararin samaniya, kayan lantarki, injina, jirgi da mota, bukatun samfuran akan silar suma sun fi hakan girma. Hanyar ƙirar ƙira ta gargajiya ta kasa biyan bukatun yau. Idan aka kwatanta da ƙirar ƙira ta gargajiya, ƙirar kwamfuta mai ƙera fasahar CAE tana da fa'idodi ƙwarai wajen haɓaka yawan aiki, tabbatar da ingancin samfuri, rage tsada da rage ƙarfin aiki.

1. Kayan lantarki da sadarwa:

2. Kayan ofis;

3. Kayan gyaran motoci;

4. Kayan aikin gida;

5.Electrical kayan aiki;

6. Kiwon lafiya da kiyaye muhalli;

7. Kayayyakin masana'antu;

8.Mai hankali na wucin gadi;

9. Sufuri;

10. Kayan gini, kayan girki da bandaki da kayan aiki

Mestech ƙwararren ƙwararren masani ne wanda ya tsunduma cikin ƙera keɓaɓɓiyar allura da kuma samar da allura kusan shekaru 20. Muna da kyakkyawan injiniyan injiniya da ƙwarewar ƙwarewar masana'antu. Za mu iya tsarawa da kuma samar da ingancin ingancin allurar filastik don abokan cinikinmu. Abubuwan haɗin mu na allura suna rufe lantarki, lantarki, mota, likita, sufuri da kayan aikin masana'antu. Idan kana bukata, da fatan za a iya tuntubar mu.