Mould rarrabuwa

Short Bayani:

Mould (mold, die) babban iyali ne, yana da mahimmin matsayi a masana'antar zamani. Bayyanannen tsari yana da matukar mahimmanci don fahimtar masana'antar masana'antu.

Mould (mold, die) kayan aiki ne na musamman wanda ake amfani dashi cikin ayyukan ɗan adam. Mould rarrabuwaya hada da fadi da kewayon. A cikin zamantakewar zamani, tsohuwar tana da alaƙa da masana'antar masana'antu, wanda ke inganta ƙimar samarwa da daidaitattun sassa.

Mold kayan aiki ne na musamman da ake amfani da su a cikin ayyukan ɗan adam. Oldaramar Mould ya haɗa da kewayon da yawa. A cikin zamantakewar zamani, mould yana da alaƙa da masana'antar masana'antu, wanda ke inganta ƙimar samarwa da daidaitattun sassa.

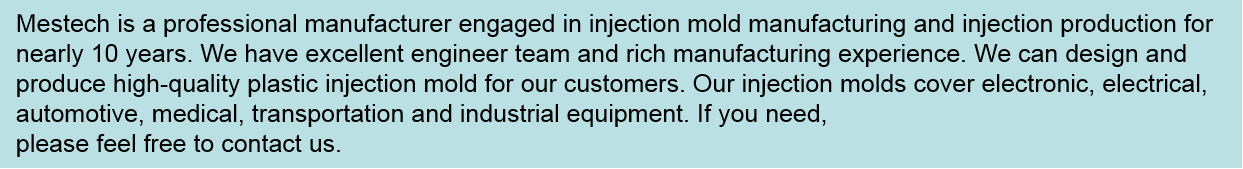

Mold shine kayan aikin fasaha wanda ke tsara (siffofi) kayan aiki zuwa cikin kayayyaki da ɓangarori tare da takamaiman fasali da girma. Ciki har da: zafin nama mutu, roba allura mold, mutu simintin mold, ƙirƙira mold, foda metallurgy mutu mold, jawo mutu, extrusion mutu, mirgina mutu, gilashin mutu, roba mold, yumbu mold, Fitar mold da sauran iri. A cikin masana'antar zamani, sifar galibi tana nuni ne da ƙirar da aka yi amfani da ita wajen samar da sassan filastik da sassan kayan aiki. Lokacin da aka yi amfani da shi don ƙirƙirar abu mai ƙarfi daga filastik ɗin ruwa, ƙarfe da sauran kayan da aka yi wa allura a raminsa, sai mu kira shi da "mage" ko "ƙira". Lokacin da aka yi amfani da shi don naushi, lankwasawa, lanƙwasawa da extrusion na m blank, galibi muna kiransa da "mutu".

An rarraba nauyin ta siffofinsa kamar haka:

Rabawa ta hanyar kayan aiki da fasahar sarrafawa, da kyawon tsayuwa za a iya raba cikin hardware mutu mold, roba filastik da musamman mold.

(1) -arfe da baƙaran ƙarfe da ƙirar ƙarfe: ƙirar filastik, ƙwanƙollar ƙwanƙwasawa, ƙirar yashi, ƙwarƙwarar buɗaɗɗu da ƙera paraffin.

Tare da saurin ci gaban filastik robobi, kyallarorin filastik suna da alaƙa da rayuwar mutane. Za'a iya raba kayan kwalliyar filastik zuwa: moldodi na allura, kayan kwalliyar extrusion, kayan aikin gas, da sauransu

(2) Kayan masarufi sun kasu kashi biyu: mutuwar simintin mutu, buga tambari ya mutu (kamar naushi ya mutu, lankwasawa ya mutu, zane ya mutu, juyawa ya mutu, raguwa ya mutu, rashin daidaito ya mutu, bulging ya mutu, siffatawa ya mutu, da sauransu), ƙirƙirar mutu (kamar kamar yadda mutuƙar ƙirƙirawa ta mutu, ɓacin rai ya mutu, da dai sauransu), extrusion ya mutu, mutuwar simintin mutu, ƙirƙirar ya mutu, da sauransu.

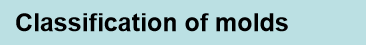

Karfe stamping mutu

1.Classification na filastik kyawon tsayuwa

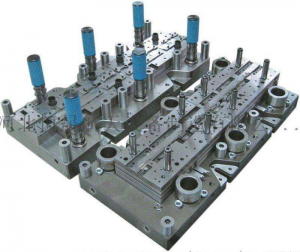

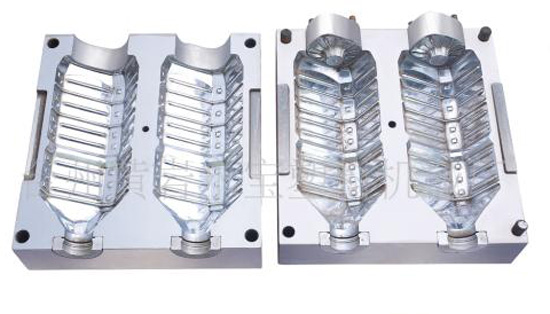

(1) Injection Mould

Injection mold wani nau'ine ne wanda ake amfani dashi don samarda sassan thermoplastic da robobi na thermosetting. Ana amfani da gyare-gyaren allura saboda yawan daidaito da inganci. Allurar gyare-gyare ita ce don ƙara filastik a cikin bututun dumama na inji mai allura. Filastik ya yi zafi ya narke. Gudura ta dunƙule ko maɓallin na'urar allurar, robobin da aka saka a cikin ramin ƙwanƙolin ta hanyar bututun ƙarfe da kuma tsarin zuƙowar ƙirar, kuma ya taurara da siffofi cikin kayayyakin allura saboda ayyukan jiki da na sinadarai. Allurar gyare-gyare gyare-gyare ne mai zagaye wanda ya ƙunshi allura, riƙe matsin lamba (sanyaya) da aiwatar da demoulding na ɓangarorin filastik.Saboda haka, gyare-gyaren allura yana da halaye na lokaci-lokaci.

Thermoplastic allura gyare-gyaren yana da ab advantagesbuwan amfãni daga gajeren gyare-gyaren sake zagayowar, high samar da ingancinsu, kananan lalacewa na narkakken kayan a kan mold, da kuma babban tsari na roba sassa tare da hadaddun siffar, bayyananniyar saman juna da kuma alama, da kuma babban girma daidaito. Koyaya, don sassan filastik tare da babban canjin kaurin bango, yana da wahala don kauce wa lahani na gyare-gyare. Anisotropy na sassan filastik shima ɗayan matsaloli ne masu inganci. Ya kamata a ɗauki dukkan matakan da suka dace don rage hakan.

Injection mold

(2) Sassakar filayen roba

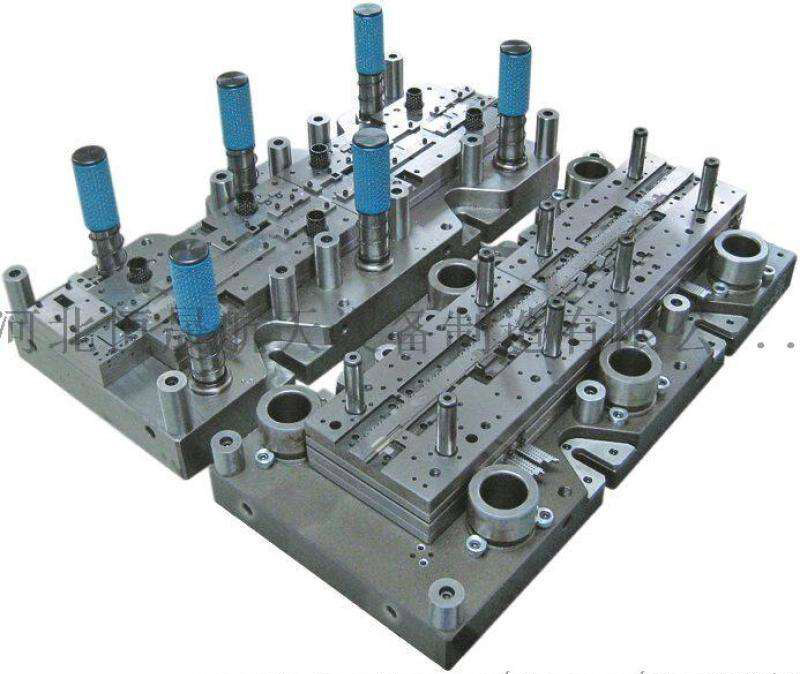

Roba extrusion gyare-gyaren wani nau'i ne na samar da hanya don sanya robobi a cikin yanayin kwararar viscous wucewa ta hanyar mutuwar tare da takamaiman fasalin giciye-sashi a babban zafin jiki da wani matsin lamba, sannan kuma tsara shi a cikin bayanin martaba mai gudana tare da buƙatar giciye-sashi a ƙananan zafin jiki Tsarin samar da kayan kwalliyar kayan kwalliya shi ne shirye-shiryen kayan kwalliya, kayan kwalliyar kwalliya, sanyaya wuri, gogewa da yankewa, aiwatar da kayayyakin da aka fitar dasu (sanyaya ko maganin zafi). A yayin aiwatar da kayan, ya kamata a mai da hankali ga daidaita yanayin zafi, saurin dunƙulewa da saurin juyawa na kowane ɓangaren dumama ganga kuma ya mutu daga mai fitarwa don samun ingantaccen bayanin martabar.

Ya kamata a biya kulawa ta musamman don daidaita ƙimar extrusion na narkewar polymer daga mutu. Domin lokacin da adadin extrusion na narkakken abu yayi kasa, extrudate din yana da shimfida mai santsi da daidaitaccen sifa, amma idan adadin extrusion na narkakken abu ya kai wani iyaka, farfajiyar za ta zama mara kyau kuma ta rasa kyalli, da kuma kifin kifin shark, bawon lemu, murdadden fasali da sauran abubuwan mamaki zasu bayyana. Lokacin da ƙimar extrusion ta ƙara ƙaruwa, farfajiyar fitowar za ta kasance ta karkatacciya, har ma ta sami rassa kuma ta fashe cikin narkakken gutsure ko silinda. Sabili da haka, sarrafa ƙimar extrusion yana da mahimmanci.

Plastics extrusion samar line

Extrusion ya mutu

(3) M samar da mold

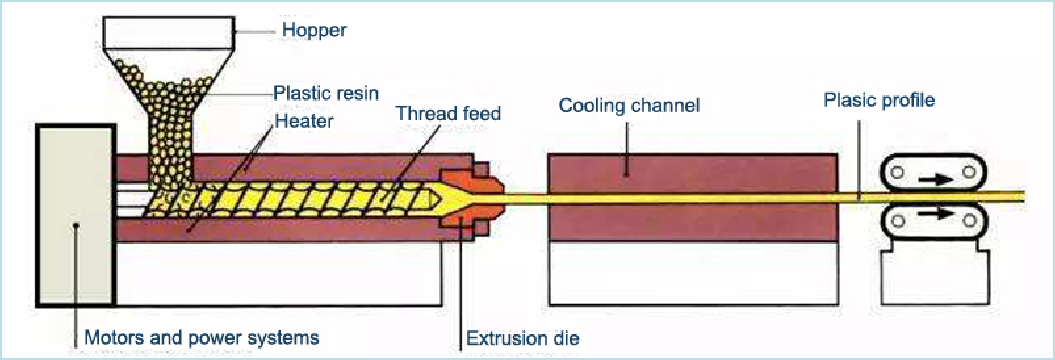

Gilashin rami mai rami ya hada da extrusion duka gyare-gyaren rami mai raɗaɗi da allurar buguwa da ke raɗaɗawa ta samar da nau'ikan nau'ikan nau'i biyu.

Hollowing gyare-gyare wani nau'in hanyar sarrafawa ne wanda yake gyara tubular ko farar takarda wanda aka yi ta ta hanyar extrusion ko allura kuma har yanzu yana cikin yanayin yin filastik a cikin ƙirar gyare-gyaren, nan da nan allurar iska mai matsewa, tilasta blank ɗin ya faɗaɗa ya tsaya a bangon bangon ramin buɗaɗa, da demould bayan sanyaya da kammalawa, don samun samfuran da ake buƙata.

Robobin da suka dace da gyare-gyaren rami sune polyethylene mai matsin lamba, low polyethylene, m polyvinyl chloride, polyvinyl chloride mai laushi, polystyrene, polypropylene, polycarbonate, da sauransu. allura duka gyare-gyaren. Amfanin extrusion duka gyare-gyaren rami mai raɗaɗi shine cewa tsarin extruder da extrusion duka kyawon tsayuwa mai sauƙi. Rashin dacewar shine kaurin bangon parison baiyi daidai ba, wanda a saukake yakan haifar da kaurin bangon kayan kayan roba. Adadin da ya dace shine zane na zane-zane na extrusion busa ƙirar ƙira mai ƙa'ida.

Allura duka gyare-gyaren yana da fa'idar daidaitaccen bangon bango kuma babu gefen tashi. Saboda ƙasan abin da ake yi wa allura, ƙasan samfurin ba zai samar da daskararren dinkakke ba, wanda ba kyakkyawa ba ne kawai amma har ma da ƙarfi. Rashin fa'ida shine kayan aiki da kayan kwalliyar da aka yi amfani da su suna da tsada, don haka ana amfani da wannan hanyar ta hanyar samar da samfuran kananan samfuran, kuma ba a yadu amfani dashi wajen amfani da silar extrusion wanda zai samar da m.

Allura duka gyare-gyaren roba

Manƙasa mai haske

(4) Mutuwar ƙirar ƙira don filastik

Mutu simintin kyawon tsayuwa kuma ana kiranta canja wurin kyawon tsayuwa. Ana saka kayan roba a cikin dakin ciyar da preheated, sannan ana amfani da matsin lamba zuwa shafi na matsi. Filastik ɗin yana narkewa a ƙarƙashin babban zazzabi da matsin lamba, kuma yana shiga cikin rami ta hanyar tsarin simintin gyare-gyaren tsari, sannu-sannu ya zama mai taurin zuciya da kafawa. Wannan kafa hanya ake kira mutu-simintin kafa, da kuma mold amfani da ake kira mutu-simintin gyare-gyaren. Ana amfani da wannan nau'ikan sifar don ƙirƙirar filastik na thermosetting.

(5) Matsawa Mold

Ressionirƙirar gyare-gyare shine ɗayan farkon hanyoyin gyare-gyaren sassan filastik. Abun matsewa shine ƙara robobi kai tsaye cikin kogon buɗewa tare da takamaiman zazzabi, sannan rufe mataccen. A karkashin aikin zafi da matsin lamba, filastik ya narke cikin yanayin gudana. Saboda aikin jiki da na sinadarai, robobi sun taurare zuwa sassan filastik tare da wasu siffa da girma a yanayin zafin dakin. Matsawa da aka fi amfani da shi ana amfani da shi ne don yin filastik na thermosetting, kamar su foda, da urea formaldehyde da melamine formaldehyde na gyaran foda, gilashin zaren da aka inganta shi da robobi, epoxy resin, DAP resin, silicone resin, polyimide da sauransu. Hakanan yana iya sarrafawa da sarrafa abubuwan ƙididdigar polyester marasa ƙaranci (DMC), robobi masu ɗaurin takarda (SMC), prefabrication. Monolithic gyare-gyaren robobi (BMC) da dai sauransu Gabaɗaya, tsarin daidaitawa na manya da ƙananan mutu na fim ɗin matsawa galibi ana matsawa, kuma matsewar ta mutu ana raba ta cikin nau'ikan uku: nau'in ambaliyar, nau'in da bai cika ambaliya ba da nau'in mai wuce gona da iri.

(6) Gwanin matsi ya mutu

Kuma aka sani da mutu 'yan wasa. An saka kayan roba a cikin dakin caji na farko, sannan sai a sanya ginshikin latsawa cikin dakin caji don kulle mutu. Ana amfani da matsa lamba zuwa filastik ta hanyar layin latsawa. Filastik ɗin yana narkewa cikin yanayin gudana a yanayin zafin jiki mai ƙarfi da matsin lamba, kuma yana ƙarfafa cikin ramin sannu a hankali ta cikin tsarin zuƙowa. Wannan hanyar kirkirar ana kiranta canjin canjin. Injectionwanƙwasa allurar matsin lamba ya dace da filastik masu ƙarfi tare da wuraren narkewa daban-daban. A ka'ida, ana iya amfani dashi don gyare-gyaren matsawa ko shigar da allurar matsin lamba. Koyaya, lokacin da zafin jiki mai ƙarfi ya kasance ƙasa da zafin ƙarfin ƙarfin, yanayin narkewa yana da ruwa mai kyau, kuma idan zafin ƙarfin tsayayyen ya fi haka, ƙarfin ƙarfin yana da girma.

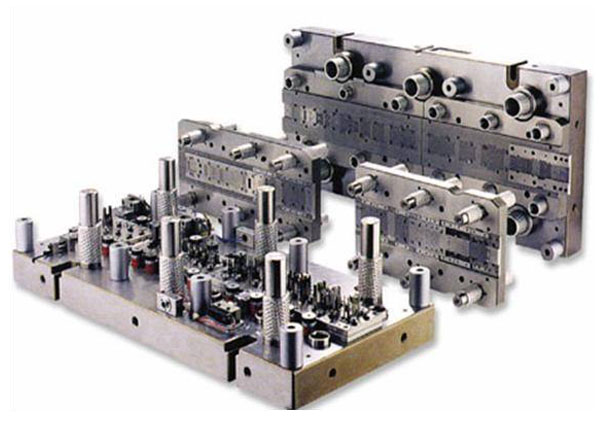

2. Rarraba kayan aiki ya mutu

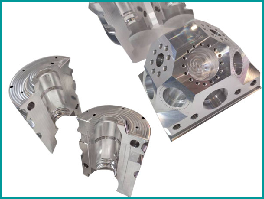

Dangane da kayan aiki da yanayin sarrafawa, ana iya raba sifar ƙarfe zuwa sifa mai zafi da ke aiki mai sanyi. Bambanci tsakanin su yana da girma.

1) Hot aiki mutu: zafi aiki mutu karfe yana nufin mutu dace da zafi nakasawa na karfe, kamar zafi extrusion mutu, mutu simintin mutu, zafi ƙirƙira mutu, zafi tashin hankali mutu, da dai sauransu Kamar yadda zafi aiki mutu aiki a karkashin babban zazzabi da matsin lamba na dogon lokaci, ana buƙatar kayan mutu don samun ƙarfin ƙarfi, taurin da kwanciyar hankali na thermal, musamman ma ƙarfin ƙarfin zafin jiki, gajiya na thermal, tauri da kuma jure juriya. Yana yafi hada da:

A. Karfe mutu simintin mutu mold: tsari shi ne allura high-zazzabi narkakken ruwa karfe a cikin mutu rami don samun da ake bukata tsarin sassa. Ana amfani da gyaran gwal na ƙarfe don yin ɓangarorin fasali na gami na aluminium, gami da tutiya, allurar magnesium da sauran gami da ba ƙarfe ba.

B. powderarfin baƙin ƙarfe mai ƙwanƙwasawa: aikin shi ne yin hoda na ƙarfe a cikin wani fasali da girma na ɗanɗano a cikin sifar, sannan kuma a dumamar da ƙyallen zuwa yanayin narkewar, ta yadda za a iya samar da shi. Ana amfani da sinadarin hoda na ƙarfe don baƙin ƙarfe, titanium, jan ƙarfe, ƙarfe, nickel da sauran kayan haɗi masu zafin jiki.

C. Metal zafi extrusion mutu: zafi aiki zafi extrusion mutu ne gabaɗaya zartar da aiki na aluminum, magnesium, karfe da sauran karafa a cikin yanayin zafin jiki mai girma, kuma fasalin ɓangaren giciye na sassan da aka samar ya canza. The zafi extrusion mutu ake bukata don samun mai kyau zafi-resistant lalacewa juriya da tempering juriya.

Karfe mutu Fitar mold

Hot extrusion mutu da bayanin martabar aluminum

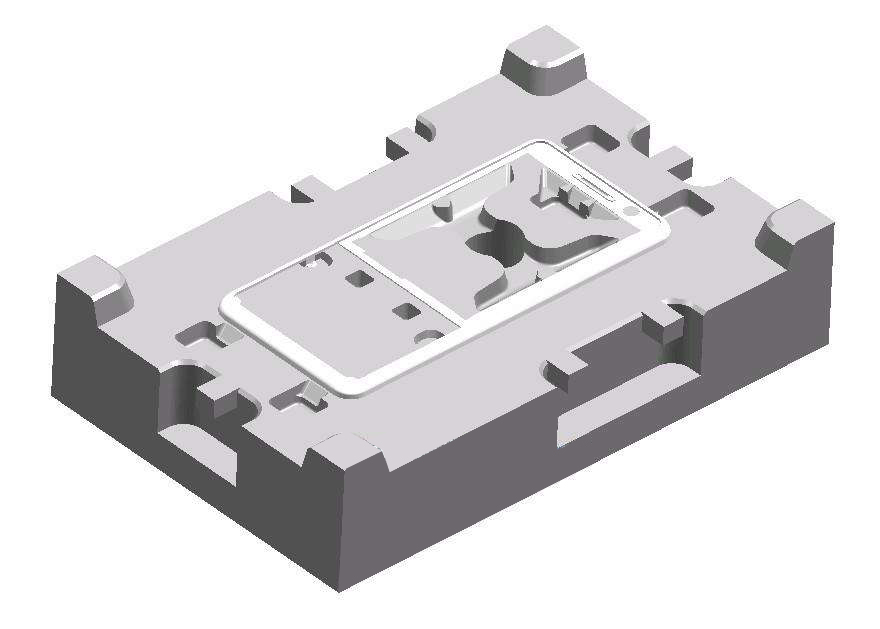

2) Sanyi mai aiki ya mutu (Stamping ya mutu): yawan aiki mai sanyi yana mutuwa galibi yana aiki a yanayin zafin ɗaki, wanda yawanci ana kiransa stamping ya mutu (kamar naushi ya mutu, lanƙwasa ya mutu, zane ya mutu, juyawa ya mutu, ƙyama ya mutu, mirgina ya mutu, bulging ya mutu , siffar mutu, da sauransu). Sashin aiki na aikin sanyi yana mutuwa gabaɗaya yana buƙatar ɗaukar matsin lamba mai yawa, lanƙwasa ƙarfi, ƙarfin tasiri da ƙarfin gogayya, don haka juriya ta nakasassu tana da girma.

A. Metal blanking mutu: ana amfani da mutuƙar ƙarfe don yanke fasali mai girma biyu daga farantin karfe. Hakanan za'a iya amfani da sassan azaman blank don lanƙwasawa, zane da ƙirƙirar su. Blanking galibi ana amfani dashi don ɓoyewa, naushi da kuma yanke ƙarfe, bakin ƙarfe, gami na aluminium, ƙarfe na jan ƙarfe da sauran faranti.

B. lankwasawa ya mutu: wani yanki ne wanda yake amfani da mutu don lanƙwasa faranti, sanduna da sashe zuwa wani kusurwa, ƙwanƙwasawa da fasali. Ya dace da karfe, bakin karfe, gami da allunan ƙarfe na ƙarfe.

C. Zane mutu: zane zane ne na zanawa, zoben zane ko mutuƙar ƙarfe don canza kayan ƙarfe zuwa silinda ko sassan siffofin akwatin. Zana mutu kayan aiki ne gama gari.

D. Kirkirar mutu: amfani da hanyar mutu ne wata hanyar samarwa wacce nakasassun filastik ke gudana akan tsayayyen yayin da ingancin ta da halayen kayan sa basu canza ba. E. Riveting die: riveting na ƙarfe wata hanya ce ta haɗa kayan aiki guda biyu ta cikin manyan kayan aiki ta hanyar ƙarfin inji. Gabaɗaya, ana amfani da riveting tsakanin faranti masu lebur. Mutuwar da aka yi amfani da ita a cikin aikin ana kiranta riveting die.

Lankwasawa ya mutu

Karfe stamping mutu

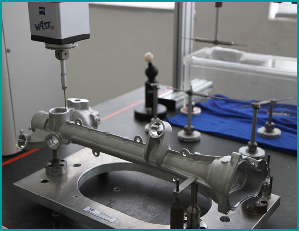

Aikace-aikacen ƙira ko mutu:

(1). Kayan lantarki da sadarwa;

(2). Kayan ofis;

(3). Abubuwan hawa na motoci;

(4). Kayan aikin gida;

(5) .Wasu kayan lantarki;

(6). Kiwon lafiya da kare muhalli;

(7). Masana'antu;

(8) .Hanyoyin kere kere;

(9). Sufuri;

(10). Kayan gini, kayan girki da bandaki da kayan aiki;