Gilashin filastik mai gaskiya

Short Bayani:

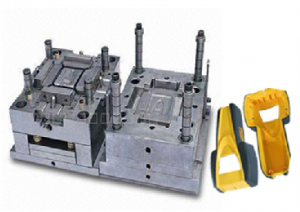

Ana amfani da samfuran filastik masu amfani a masana'antar masana'antu da rayuwar mutane a zamanin yau. Hannun allurar roba mai gaskiya yana taka muhimmiyar rawa a fagen kafa filastik.

Saboda fa'idodi na nauyin nauyi, taurin kirki, sassauƙa sauƙaƙa da ƙarancin farashi, ana ƙara amfani da robobi don maye gurbin gilashi a cikin masana'antun zamani da kayayyakin yau da kullun, musamman a kayan kimiyyar gani da masana'antu. Amma saboda wadannan bangarorin na bayyane suna bukatar kyakyawan haske, juriya mai lalacewa da kuma taurin tasiri mai kyau, yakamata ayi aiki da yawa akan kayan robobi da kuma tsari, kayan aiki da kuma kyallen kayan allurar gaba daya don tabbatar da cewa robobin da ake amfani dasu don maye gurbin gilashi (wanda ake kira nan gaba a matsayin filastik masu haske) suna da ingancin ƙasa mai kyau, don biyan bukatun amfani.

I --- Gabatarwa na Robobi Masu Gaskiya a Amfani da Kowa

A halin yanzu, robobi masu haske da aka saba amfani dasu a kasuwar sune polymethyl methacrylate (PMMA), polycarbonate (PC), polyethylene terephthalate (PET), polyethylene terephthalate-1,4-cyclohexanedimethyl glycol ester (PCTG), Tritan Copolyester (Tritan), transparent ny , acrylonitrile-styrene copolymer (AS), polysulfone (PSF), da dai sauransu Daga cikin su, PMMA, PC da PET sune filastik da aka fi amfani da su wajen gyaran allura.

Guduro filastik mai gaskiya

2.PC (Polycarbonate)

Dukiya:

(1). Launi marar launi da bayyane, watsawa na 88% - 90%. Yana da ƙarfin ƙarfi da ƙarfin roba, ƙarfin tasiri mai tasiri da faɗin amfani da yanayin zafin jiki.

(2). High nuna gaskiya da dyeing kyauta;

(3). Shirƙirar ƙira yana da ƙasa ((0.5% -0.6%) kuma kwanciyar hankali girma yana da kyau.Da yawa 1.18-1.22g / cm ^ 3.

(4). Kyakkyawan jinkirin harshen wuta da jinkirin harshen wuta UL94 V-2. Yanayin zafin yanayi mara kyau kusan 120-130 ° C.

(5). Kyakkyawan halayen lantarki, kyakkyawan aikin rufi (zafi, yanayin zafin jiki na iya kiyaye kwanciyar hankali na lantarki, shine mafi kyawun kayan don ƙera sassan lantarki da na lantarki);

(6) HDTis babba;

(7). Kyakkyawan yanayin yanayi;

(8). PC bashi da kamshi kuma baya cutarwa ga jikin mutum kuma ya dace da lafiyar tsafta.

Aikace-aikace:

(1). Haske na gani: ana amfani dashi don kera manyan fitilun fitilu, gilashin kariya, ganga da dama gangaren kayan kida na gani, da dai sauransu. Hakanan za'a iya amfani dashi sosai don kayan aiki masu haske akan jirgin sama.

(2). Kayan lantarki da lantarki: Polycarbonate kyauta ce mai kyau don kera masu haɗawa, firam murfi, masu rike da bututu, inshorar daji, bawon tarho da sassanta, bawon batir na fitilun ma'adanai, da dai sauransu. Hakanan za'a iya amfani dashi don yin sassan tare da daidaiton girma mai girma , kamar karamin fayafai, tarho, kwamfuta, rakodi na bidiyo, musayar tarho, siginar rediyo da sauran kayan sadarwa. Polycarbonate na bakin ciki touch ana amfani dashi ko'ina azaman karfin wuta. Ana amfani da fim na PC don jaka masu jaka, kaset, bidiyo mai launi, da dai sauransu.

(3). Inji da kayan aiki: Ana amfani dashi don kera giya daban-daban, akwatuna, giya na tsutsa, bearings, cams, bolts, levers, crankshafts, ratchets da sauran sassan kayan masarufi da kayan aiki, kamar bawo, murfi da firam.

(4). Kayan aikin likitanci: kofuna, silinda, kwalabe, kayan hakora, kwantena kwayoyi da kayan aikin tiyata wadanda za a iya amfani da su don aikin likita, har ma da kodar da aka kera, huhun roba da sauran kayan aikin na wucin gadi.

3.PET (Polyethylene terephthalate)

Dukiya:

(1). PET resin ne opalescent translucent ko marar launi m, tare da dangi yawa 1.38g / cm ^ 3 da watsa 90%.

(2). PET robobi suna da kyawawan kayan gani, kuma robobin PET marasa kyau suna da kyakkyawan gani na gani.

(3). Tenarfin ƙarfin PET yana da ƙarfi sosai, wanda ya ninka na PC sau uku. Tana da mafi tsananin tauri a cikin robobi na thermoplastic saboda kyakkyawar juriya da canjin U-canji, gajiya da gogayya, ƙananan lalacewa da tsananin tauri. An sanya shi cikin kayan sifa-masu walƙiya kamar su kwalban roba da fina-finai da finafinan filastik.

(4). Yanayin zafi mara kyau 70 ° C. Rage harshen wuta bai fi PC ba

(5). Kwalbobin PET suna da ƙarfi, a bayyane, ba masu guba ba, ba sa iya lalacewa kuma suna da nauyi.

(6). Yanayin yanayi yana da kyau kuma ana iya amfani dashi a waje na dogon lokaci.

(7). Ayyukan rufi na lantarki yana da kyau, kuma ƙarancin zafin jiki baya tasiri.

Aikace-aikace:

(1). Aikace-aikacen kwalban kwalliya: Aikace-aikacensa ya haɓaka daga abin sha mai ƙanshi zuwa kwalbar giya, kwalban mai cin abinci, kwalban ƙanshi, kwalban magani, kwalban kwalliya da sauransu.

(2). Kayan lantarki da lantarki: masu haɗin keɓaɓɓu, bututun iska mai haɗawa, bawo kewaye, bawo na wuta, bawo mai canza wuta, kayan haɗi na TV, tuners, sauyawa, bawoyin lokaci, fiyuwan atomatik, maɓuɓɓuka masu motsi da maimaitawa, da dai sauransu.

(3). Kayan haɗin motoci: kamar murfin bangon rarraba, murfin wuta, bawuloli daban-daban, ɓangarorin shaye-shaye, murfin mai rarrabawa, murfin kayan aikin auna, ƙaramin motar, da dai sauransu, suma za su iya amfani da kyawawan kayan da ke jikinsu, mai sheki da tsayayyar PET don kera motar waje sassa.

(4). Kayan aiki da kayan aiki: kayan kerawa, cam, gidan famfo, kura mai juyawa, firam mai motsi da sassan agogo, ana iya amfani dasu don kwanon rufi na injin na microwave, rufi iri-iri, tallan waje da samfura

(5). PET roba kafa tsari. Ana iya yin allura, fitarwa, hurawa, mai rufi, haɗi, injiniya, zaɓaɓɓun lantarki, ƙwanƙwasa haske da bugawa.

Ana iya yin PET a cikin fim wanda kauri daga 0.05 mm zuwa 0.12 mm ta hanyar miƙa tsari. Fim din bayan ya miƙa yana da taurin kirki da tauri. Fim ɗin PET mai nuna gaskiya shine mafi kyawun zaɓi na fim mai kariya don allon LCD. A lokaci guda, fim ɗin PET shima abu ne na IMD / IMR gama gari saboda kyawawan kayan aikin sa.

Concididdigar kwatancen PMMA, PC, PET sune kamar haka:

Dangane da bayanai a cikin Table 1, PC shine zaɓi mafi kyau don cikakken aiki, amma yawanci saboda tsadar kayan albarkatun ƙasa da wahalar aikin gyaran allura, don haka PMMA har yanzu shine babban zaɓi. (Don samfuran da ke da cikakkun buƙatu), yayin da PET galibi ana amfani dashi a cikin marufi da kwantena saboda yana buƙatar miƙa shi don samun kyawawan kayan aikin injiniya.

II --- Abubuwan kayan jiki da aikace-aikacen filastik masu haske waɗanda aka yi amfani da su a cikin inginin allura:

Filastik masu gaskiya suna da farko suna da cikakken haske, kuma abu na biyu, dole ne su sami ƙarfi kuma su sa juriya, juriya mai tasiri, juriya mai kyau mai kyau, juriya mai kyau da kuma ƙarancin shan ruwa. Ta wannan hanyar ne kawai za su iya biyan buƙatun nuna gaskiya kuma ba su canzawa na dogon lokaci ana amfani da su. Aikin da aikace-aikacen PMMA, PC da PET ana kwatanta su kamar haka.

1. PMMA (Acrylic)

Dukiya:

(1). Launi marar launi, mai haske, mai gaskiya 90% - 92%, tauri fiye da gilashin siliki fiye da sau 10.

(2). Tantancewar ido, insulating, aiwatarwa da yanayin yanayi.

(3). Yana yana da babban haske da haske, mai kyau zafi juriya, taurin, rigidity, zafi nakasawa zazzabi 80 ° C, lankwasa ƙarfi 110 Mpa.

(4) .Yawan yawa 1.14-1.20g / cm ^ 3, zafin jiki mara kyau 76-116 ° C, yana yin ƙanƙancewa 0.2-0.8%.

(5). Arirgar fadada coefficient ne 0.00005-0.00009 / ° C, thermal nakasawar zafin jiki ne 68-69 ° C (74-107 ° C).

(6). Narkewa cikin kwayoyin kaushi kamar carbon tetrachloride, benzene, toluene dichloroethane, trichloromethane da acetone.

(7). Ba mai guba ba kuma mai muhalli.

Aikace-aikace:

(1). Ana amfani dashi ko'ina a sassan kayan aiki, fitilun mota, ruwan tabarau na gani, bututu masu haske, inuwar fitilar hasken wuta.

(2). PMMA resin abu ne mai guba kuma mai mahalli, wanda za'a iya amfani dashi don samar da kayan abinci, kayan tsafta, da dai sauransu.

(3). Yana da kyakkyawan kwanciyar hankali na sinadarai da yanayin yanayi. Gudun PMMA ba sauki ba ne don samar da kaifin tarkace lokacin da aka karye shi. Ana amfani dashi azaman plexiglass maimakon gilashin silica don yin ƙofofin tsaro da tagogi.

PMMA m bututu hadin gwiwa

PMM 'ya'yan itace farantin

PMMA murfin fitila mai haske

Tebur 1. Kwatancen aiki na robobi masu haske

| Dukiya | Yawa (g / cm ^ 3) | Siarfin ƙarfi (Mpa) | Carfin mara ƙarfi (j / m ^ 2) | Watsawa (%) | Yanayin zafi mara kyau (° C) | Abin da aka ba da izinin ruwa (%) | Shimar raguwa (%) | Sa juriya | Tsarin kemikal |

| Kayan aiki | |||||||||

| PMMA | 1.18 | 75 | 1200 | 92 | 95 | 4 | 0.5 | talakawa | mai kyau |

| PC | 1.2 | 66 | 1900 | 90 | 137 | 2 | 0.6 | matsakaita | mai kyau |

| PET | 1.37 | 165 | 1030 | 86 | 120 | 3 | 2 | mai kyau | kwarai da gaske |

Bari mu mai da hankali kan kayan PMMA, PC, PET don tattauna kadarorin da allurar allurar roba mai haske kamar haka:

III --- Matsalolin gama gari da za a lura dasu yayin aiwatar da Injin Robobi Masu Gaskiya.

Filastik masu gaskiya, saboda yawan watsa su, dole ne su buƙaci ingancin samfuran filastik.

Dole ne su kasance ba su da wata lahani kamar tabo, bushe-bushe, farin fata, halo, hazo mai duhu, canza launin launi da ƙyalli mai haske. Sabili da haka, tsananin ko ma buƙatu na musamman ya kamata a kula da su cikin ƙirar albarkatun ƙasa, kayan aiki, ƙira har ma da samfuran yayin aikin allurar gaba ɗaya.

Abu na biyu, saboda robobi masu haske suna da narkar da ruwa da kuma rashin ruwa mai kyau, don tabbatar da ingancin samfuran samfuran, yakamata a daidaita sifofin aiki kamar zazzabi mafi girma, matsin allura da saurin allura dan kadan, don haka za'a iya cika robobi da kyawon wuta. , kuma damuwa na ciki ba zai faru ba, wanda zai haifar da nakasa da fasa kayayyakin.

Ya kamata a kula da maki masu zuwa a cikin shirye-shiryen albarkatun kasa, buƙatun kayan aiki da kayan ƙira, aiwatar da allurar ƙira da kuma kula da albarkatu na samfuran.

1 Shiri da bushewar kayan aiki.

Saboda duk wani datti da ke cikin robobi na iya shafar bayyanuwar kayayyakin, ya zama dole a kula da hatimi a cikin aikin adanawa, jigilar kaya da ciyarwa don tabbatar da cewa albarkatun kasa suna da tsabta. Musamman lokacin da ɗanyen kaya ya ƙunshi ruwa, zai lalace bayan dumama, saboda haka dole ne ya zama bushe, kuma lokacin da ake yin allurar allurar, ciyarwar dole ne tayi amfani da busasshiyar hopper. Har ila yau lura cewa a cikin aikin bushewa, ya kamata a tace abubuwan da ke cikin iska kuma a cire danshi domin tabbatar da cewa ba a gurbata albarkatun kasa ba. Ana nuna aikin bushewa a cikin Table 2.

Automobile PC fitilar mota

Murfin PC na gaskiya don kwantena

PC farantin

Table 2: Bushewa tsari na m robobi

| bayanai | zazzabi mai bushewa (0C) | lokacin bushewa (awa) | zurfin abu (mm) | ra'ayi |

| abu | ||||

| PMMA | 70 ~ 80 | 2 ~ 4 | 30 ~ 40 | Bugawar bushewar iska mai zafi |

| PC | 120 ~ 130 | > 6 | <30 | Bugawar bushewar iska mai zafi |

| PET | 140 ~ 180 | 3 ~ 4 | Na'urar bushewa mai ci gaba |

2. Wankewar ganga, dunƙule da kayan haɗi

Don hana gurɓacewar albarkatun ƙasa da wanzuwar tsofaffin abubuwa ko ƙazanta a cikin ramin dunƙule da kayan haɗi, musamman maɗaura da ƙarancin kwanciyar hankali na zafin jiki, ana amfani da wakilin tsabtace tsabtace sassan kafin da bayan rufewa, don haka ƙazamta ba za a iya bin su. Lokacin da babu dillalan tsaftacewa, ana iya amfani da PE, PS da sauran mayuka don tsaftace dunƙulen. Lokacin da rufewa na ɗan lokaci ya faru, don hana abu daga kasancewa a zazzabi mai ƙarfi na dogon lokaci da haifar da lalacewa, ya kamata a rage bushewa da zazzabin ganga, kamar PC, PMMA da sauran zafin jiki na ganga ya zama ƙasa da 160 C. ( Zazzabin hopper ya zama ƙasa da 100 C don PC)

3. Matsalolin da suke buƙatar kulawa cikin ƙirar ƙira (haɗe da ƙirar samfur) Don hana ƙarancin komawa baya ko sanyaya mara kyau wanda ya haifar da ƙarancin filastik, lahani na ƙasa da lalacewa, ya kamata a mai da hankali ga mahimman bayanai yayin tsara fasalin.

A). Kaurin bangon ya zama daidai ne yadda ya kamata kuma gangaren lalata ya zama babba sosai;

B). Mika mulki ya zama a hankali. Canji mai kyau don hana kusurwa masu kaifi. Dole ne a sami rata a gefuna masu kaifi, musamman a cikin kayayyakin PC.

C). kofa. Ya kamata mai gudu ya zama mai fadi da gajere kamar yadda ya kamata, kuma ya kamata a saita matsayin ƙofar gwargwadon ƙanƙantar da yanayin shigar ƙwaiƙwoyo, kuma ya kamata a yi amfani da rijiyar da ke cikin firiji idan ya zama dole.

D). Yaren mutuƙar ya zama mai santsi da ƙarancin ƙarfi (zai fi dacewa ƙasa da 0.8);

E). Sharar ramuka. Tankin dole ne ya isa isar da iska da gas daga narkewar cikin lokaci.

F). Ban da PET, kaurin bangon bai kamata ya zama siriri ba, gaba ɗaya bai ƙasa da l mm ba.

4. Matsalolin da ke buƙatar kulawa a cikin aikin gyare-gyaren allura (gami da buƙatu don injunan gyare-gyaren allura) Domin rage damuwa na ciki da ingancin ingancin farfajiyar, ya kamata a mai da hankali ga abubuwan da ke tafe a cikin aikin gyaran allura.

A). Ya kamata a zaba keɓaɓɓiyar dunƙule da injin yin allura tare da bututun ƙarfe mai sarrafa zafin jiki daban.

B). Yakamata a yi amfani da danshi mai tsananin zafi a yanayin zafin jiki na allura ba tare da bazuwar filastik na roba.

C). Matsi na allura: gabaɗaya mafi girma don shawo kan lahani na ƙananan narkewar narkewa, amma matsin lamba mai yawa zai haifar da damuwa na ciki, wanda zai haifar da wahalar lalacewa da nakasawa;

D). Gudun allura: Game da gamsarwa mai cikawa, ya dace gaba ɗaya ya zama ƙasa, kuma ya fi kyau a yi amfani da allurar mataki-a hankali-mai saurin-sauri;

E). Lokacin riƙe matsin lamba da lokacin yin ta: a yanayin gamsarwa da samfur ba tare da samar da baƙin ciki da kumfa ba, ya zama ya yi gajarta yadda zai yiwu don rage lokacin zama a narke a cikin ganga;

F). Rewwanƙwasa gudu da matsin lamba na baya: a kan sharaɗin gamsar da ingancin filastik, ya kamata ya zama ƙasa-wuri don hana yuwuwar zuriya;

G). Wan zafin yanayi: qualityarancin sanyaya na samfuran yana da tasiri sosai akan ingancin, saboda haka zafin jiki mai ƙyalli dole ne ya iya sarrafa aikin sa daidai, idan zai yiwu, zafin jiki mai ƙyalli ya zama mafi girma.

5. Sauran fannoni

Don hana lalacewar ingancin farfajiyar, yakamata ayi amfani da wakilin saki kamar yadda zai yiwu a cikin gyaran allura gabaɗaya, kuma abu mai sake amfani dashi bazai wuce 20% ba.

Ga dukkan samfuran banda PET, yakamata a aiwatar da aiki don kawar da damuwa na ciki, PMMA ya kamata a bushe a cikin 70-80 ° C yanayin iska mai zafi na awanni 4, PC ya kamata a zafafa a 110-135 ° C cikin iska mai tsabta, glycerin , paraffin na ruwa, da dai sauransu Lokaci ya dogara da samfurin, kuma matsakaicin buƙata ya fi awa 10. Dole ne PET ya shiga shimfida bixial don samun kyawawan kayan aikin injiniya.

PET tubes

PET kwalban

PET harka

IV --- Fasaha Molding Fasaha na Transparent Plastics

Hanyoyin fasaha na robobi masu haske: Bayan matsalolin yau da kullun, robobi masu haske suna da wasu halaye na fasaha, waɗanda aka taƙaita su kamar haka:

1. Halayen tsari na PMMA. PMMA yana da babban danko da rashin ruwa mai kyau, saboda haka dole ne ayi masa allura da zazzabi mai ƙarfi da matsin lamba. Tasirin zafin jiki na allura ya fi ƙarfin allura, amma ƙaruwar allurar yana da amfani don haɓaka ƙimar ƙarancin kayayyakin. Yanayin zafin jiki na allura yana da fadi, yanayin narkewa shine 160 ° C kuma zafin zafin ya zama 270 ° C don haka yanayin kewayon yanayin zafin jiki yana da fadi kuma aikin yana da kyau. Sabili da haka, don haɓaka ruwa, zamu iya farawa da zafin jiki na allura. Tasiri mara kyau, juriya mara kyau, mai sauƙin karce, mai sauƙin fashewa, saboda haka ya kamata mu inganta yawan zafin jiki na mutuwar, inganta tsarin ƙyamar jiki, don shawo kan waɗannan lahani.

2. Halayen tsari na PC PC suna da babban ɗanko, zazzabi mai narkewa da ƙarancin ruwa, saboda haka dole ne ayi masa allura a zazzabi mafi girma (tsakanin 270 da 320T). Idan aka kwatanta da magana, yanayin kewayon yanayin zafin jiki yana da ɗan kaɗan, kuma aiwatarwa ba shi da kyau kamar PMMA. Matsawar allura ba ta da wani tasiri a kan ruwa, amma saboda yawan danko, har yanzu yana buƙatar ƙarin matsin lamba mai girma. Don hana damuwa na ciki, lokacin riƙewa ya zama takaice kamar yadda zai yiwu. Theididdigar ƙimar yana da girma kuma girman yana daidaita, amma damuwa na ciki na samfurin yana da girma kuma yana da sauƙi don tsagewa. Sabili da haka, yana da kyau a inganta ruwa ta hanyar kara zafin jiki maimakon matsin lamba, kuma a rage yiwuwar fashewa ta hanyar kara zafin jiki na mutu, inganta tsarin mutu da bayan magani. Lokacin da saurin allura ya yi kasa, kofar tana da saurin haduwa da sauran lahani, ya kamata a sarrafa zafin bututun iska daban, yanayin zafin jiki ya zama babba, kuma juriyar mai gudu da kofa ya zama karami.

3. Halaye na fasaha na PET PET suna da zafin jiki mai girma da kuma taƙaitaccen kewayon daidaita yanayin zafin jiki, amma yana da ruwa mai kyau bayan narkewa, don haka yana da ƙarancin aiki, kuma ana ƙara na'urar da ake tsawaitawa a cikin bututun. Mechanicalarfin inji da aikin bayan allurar ba ta da girma, dole ne ta hanyar miƙa tsari da gyare-gyare na iya inganta aikin. Ingantaccen iko na zafin jiki na mutuwa shine don hana warping.

Saboda mahimmin mahimmanci na nakasa, ana ba da shawarar mai gudu mai zafi ya mutu. Idan zafin jikin wanda ya mutu yayi girma, mai sheki a saman zai zama mara kyau kuma demoulding din zaiyi wahala.

Tebur 3. Sigogin Gyara Allurar Mita

| kayan aikin siga | matsa lamba (MPa) | dunƙule gudu | ||

| allura | ci gaba da matsa lamba | baya matsa lamba | (rpm) | |

| PMMA | 70 ~ 150 | 40 ~ 60 | 14.5 ~ 40 | 20 ~ 40 |

| PC | 80 ~ 150 | 40 ~ 70 | 6 ~ 14.7 | 20 ~ 60 |

| PET | 86 ~ 120 | 30 ~ 50 | 4.85 | 20 ~ 70 |

| kayan aikin siga | matsa lamba (MPa) | dunƙule gudu | ||

| allura | ci gaba da matsa lamba | baya matsa lamba | (rpm) | |

| PMMA | 70 ~ 150 | 40 ~ 60 | 14.5 ~ 40 | 20 ~ 40 |

| PC | 80 ~ 150 | 40 ~ 70 | 6 ~ 14.7 | 20 ~ 60 |

| PET | 86 ~ 120 | 30 ~ 50 | 4.85 | 20 ~ 70 |

V --- lahani na sassan roba

Anan zamu tattauna ne kawai game da lahani waɗanda ke shafar gaskiyar kayayyakin. Akwai yiwuwar lahani masu zuwa:

Laifin samfura masu haske da hanyoyin shawo kansu:

1 Craze: rashin damuwa na damuwa na ciki yayin cikawa da sandaro, da kuma damuwar da aka samar a madaidaiciyar hanya, sa gudan gudan ya karkata zuwa sama, yayin da tsarin da ba ya kwarara yake samar da filasha filashi tare da fizgar rarrabuwa daban-daban. Lokacin da ya fadada, fasa zai iya faruwa a cikin samfurin.

Hanyoyin shawo kan sune: tsabtace kayan kwalliya da ganga na injin mai inji, bushe kayan masarufi yadda yakamata, kara hayakin hayaki, kara karfin allura da matsin lamba na baya, da kuma hada mafi kyawun kayan. Idan kayan PC zasu iya zafafa sama da 160 ° C na mintuna 3 - 5, to za'a iya sanyaya ta yanayi.

2. Bubble: Ruwa da sauran iskar gas a cikin guduro ba za a iya yin amfani da su ba (yayin aiwatar da ƙarancin ƙira) ko kuma "kumfa na kumfa" an ƙirƙira su saboda rashin cika ƙwanƙolin da kuma saurin matsewar farfajiyar farfajiyar. Hanyoyin shawo kan sun hada da kara shaye shaye da bushewa sosai, kara kofa a bangon baya, kara matsi da sauri, rage zafin jiki mai narkewa da tsawan lokacin sanyaya.

3. Haskakawar farfajiyar ƙasa: galibi saboda tsananin ƙarancin mutuwar, a gefe guda kuma, cunkoson wuri, don haka resin ba zai iya kwafin yanayin farfajiyar mutuwar ba, duk waɗannan suna sa farfajiyar mutuƙar ta zama mara daidaituwa , kuma sanya samfurin rasa mai sheki. Hanyar shawo kan wannan matsalar ita ce ta ƙara zafin jiki mai narkewa, yawan zafin jiki, matsin allura da saurin allura, da tsawan lokacin sanyaya.

4. Tsarin girgizar ƙasa: ƙwanƙwasa da aka kafa daga tsakiyar ƙofar madaidaiciya. Dalilin shi ne cewa narkarwar narkewar tayi yawa, kayan gaban gaba sun takaita a cikin ramin, sannan kayan sun karye ta cikin yanayin matsewar, wanda hakan ya haifar da daskararwar fuska Hanyoyin shawo kan sune: ƙara ƙarfin allura, lokacin allura, lokacin allura da sauri, ƙaruwar yanayin zafin jiki, zaɓar ƙwayoyin da suka dace da haɓaka rijiyoyin sanyi.

5. Farin ciki. Fog halo: Yawanci ana haifar da shi ta hanyar turɓayawa zuwa cikin kayan ƙarancin iska ko yawan ɗumbin abubuwan danshi. Hanyoyi masu nasara sune: cire ƙazantar inji mai inji, tabbatar da isasshen bushewar kayan albarkatun filastik, daidai sarrafa zafin jiki mai narkewa, ƙara yawan zafin jiki, ƙara matsa lamba na baya da gyare-gyaren allura da rage zagayen allura. 6. Farin hayaki. Black tabo: Yawanci yana faruwa ne saboda ruɓewa ko lalacewar maɓuɓɓugar da ke cikin ganga wanda ya haifar da zafin rana na gida a cikin ganga. Hanyar shawo kan ita ce ta rage yawan zafin jiki na narkewa da lokacin zama na albarkatun kasa a cikin ganga, da kuma kara ramin shaye-shaye.

Kamfanin na Mestech ya kware wajan samarwa kwastomomi fitila mai haske, kayan aikin likitancin kayan kwalliya da kayan allura. Idan kana bukatar wannan, sai a tuntube mu. Muna farin cikin samar muku da waɗancan hidiman.