Roba electroplating da injin plating

Short Bayani:

Yin amfani da wutar lantarki da zana abubuwa iri biyu ne gama gari don ƙara murfin ƙarfe zuwa sassan filastik. Wannan tsari na iya kara juriya da lalacewar sassan sassan, kara karfin karfe da kuma kawata bayyanar.

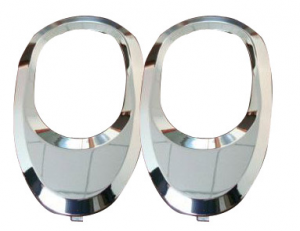

Idan aka kwatanta da spraying paint, filastik electroplating da injin plating yana da mafi alh wearri lalacewa juriya, lalata juriya da kuma musamman ƙarfe luster. Ana amfani dashi galibi a wasu sassan samfuran samfuran, kamar gidajen kayan masarufi na multimedia, shari'o'in agogo masu kaifin baki, maɓallan, masu riƙe fitila, fitila da kayan ado.

Ka'idodin sanya wutar lantarki da zoben ruwa daban, kuma abubuwan da ake amfani dasu da kuma sakamakonsu ya sha bamban. Bari mu gabatar a kasa:

1. Electroplating na roba

Roba electroplating shine tsarin nitsar da sassan roba a cikin wutan lantarki da kuma sanya barbashin karfe akan aikin yanki ta hanyar loda halin yanzu ko aikin sinadarai. Bayan zaban lantarki, farfajiyar farfajiyar azurfa ce, ƙaramar azurfa da azurfa mai launin toka.

Abubuwan robobin ABS sun kasance an sarrafa su ta hanyar azurfa nitrate sunadarai sunadarai na jan karfe, colloidal palladium PD chemical nickel direct plating don samar da layin gudanarwa tare da mannewa mai kyau akan farfajiyarta, sannan kuma wasu karafa an sanya su lantarki.

Ana yin wutan lantarki a cikin ruwan sha na lantarki, don haka ake kiran sa "electroplating ruwa", "hydropower plating". Mafi yawancin mutane sune plating na jan karfe a saman filastik, nickel chromium, chromium trivalent, launin bindiga, nickel lu'u-lu'u da sauransu.

A ka'ida, dukkan robobi ana iya sanya su ta lantarki, amma a yanzu ABS, ABS + PC ne kawai suka fi cin nasara, amma mannewar murfin lantarki a sauran robobin ba ya gamsuwa. Tsarin aikin zaɓar lantarki abu ne mai sauƙi kuma baya buƙatar fesa share fage kafin da bayan plating. Shafin yana da kyau mannewa, lokacin farin ciki da ƙananan farashi.

2. Plastics injin plating (Jiki Kuzari Deposition-PVD)

Injin plating yafi hada danshi evaporation, sputtering da ion plating. Dukansu suna sanya finafinai da ƙarfe iri-iri iri daban-daban akan fuskar roba

sassa ta distillation ko sputtering karkashin injin. Ta wannan hanyar, ana iya samun murfin saman bakin ciki sosai.

Injin plating yafi hada da injin danshin plating, sputtering plating da ion plating. Ana amfani da su duka don ɗora karafa daban-daban a saman ɓangarorin filastik ta hanyar ɓoyewa ko zugawa a ƙarƙashin yanayi na danshi.

Fim ɗin da ba na ƙarfe ba, ta wannan hanyar zai iya zama siraran siraran bakin ƙasa, kuma yana da fa'idodi na musamman na saurin sauri da mannewa mai kyau, amma farashin ma ya fi girma, gabaɗaya ana amfani da shi don kwatankwacin, kayan aiki na aiki don rufin ƙarshen ƙarshen zai iya samfurori.

Ana amfani da injin a cikin robobi kamar ABS, PE, PP, PVC, PA, PC, PMMA, da dai sauransu.

Za'a iya yin amfani da kayan kwalliyar inkila tare da nau'ikan karafa, kamar su aluminium, azurfa, tagulla da zinare, waɗanda suke da maɓallin narkewa fiye da wayar tungsten.

Motocin ABS na Automobile

Sassan filastik tare da zafin lantarki na nickle

Gloananan sassan filastik da aka sanya su da lantarki

Gloananan sassan zinare masu launuka da aka zaɓa a cikin lantarki

3. Plastics injin plating (Jiki Kuzari Deposition-PVD)

Injin plating yafi hada danshi evaporation, sputtering da ion plating. Dukansu suna sanya finafinai da ƙarfe iri-iri iri daban-daban akan fuskar roba

sassa ta distillation ko sputtering karkashin injin. Ta wannan hanyar, ana iya samun murfin saman bakin ciki sosai.

Injin plating yafi hada da injin danshin plating, sputtering plating da ion plating. Ana amfani da su duka don ɗora karafa daban-daban a saman ɓangarorin filastik ta hanyar ɓoyewa ko zugawa a ƙarƙashin yanayi na danshi.

Fim ɗin da ba na ƙarfe ba, ta wannan hanyar zai iya zama siraran siraran bakin ƙasa, kuma yana da fa'idodi na musamman na saurin sauri da mannewa mai kyau, amma farashin ma ya fi girma, gabaɗaya ana amfani da shi don kwatankwacin, kayan aiki na aiki don rufin ƙarshen ƙarshen zai iya samfurori.

Ana amfani da injin a cikin robobi kamar ABS, PE, PP, PVC, PA, PC, PMMA, da dai sauransu.

Za'a iya yin amfani da kayan kwalliyar inkila tare da nau'ikan karafa, kamar su aluminium, azurfa, tagulla da zinare, waɗanda suke da maɓallin narkewa fiye da wayar tungsten.

Lampshade injin saka sassan filastik

UV injin plating roba sassa

Vacuum plating na filastik yana nuna kofin

Nano launi injin plating roba sassa

Menene banbanci tsakanin zafin lantarki da filastik injin sakawa?

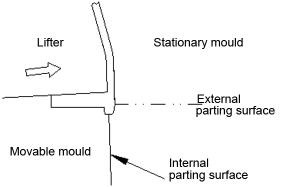

(1) Vacuum plating tsari ne na sutura a cikin layin fesawa da wutar makera, yayin da zaɓin lantarki shine tsari a cikin ruwa mai ruwa. Saboda yana fesa fenti, kwalliyar kwalliya ba ta dace da samfuran fasali mai rikitarwa ba, yayin da zafin wutan lantarki ba shi da kamanni.

(2) Fasahar sarrafawa, kamar rufin rufin manne filastik, ana iya taƙaita ta kawai: lalacewar ƙasa na asali, dedusting, electrostatic hazo, fesa turaren UV, maganin UV, ƙarancin rufi, dedusting, fesa farfajiyar ƙasa (za'a iya ƙara maida hankali kan launi) , warkarwa, kayayyakin da aka gama; coatingarfin ruɓaɓɓen iska yana iyakance ta tsari, kuma bai dace da sarrafa samfuran tare da yanki mai girma ba saboda aiki. Tsarin fasaha ba shi da kyakkyawan sarrafawa, kuma ƙimar lahani tana da yawa.

Roba electroplating (gaba daya ABS, PC / ABS): sunadarai deoiling hydrophilic coarsening raguwa preimpregnation palladium kunnawa hanzarin electroless nickel plating hydrochloric acid kunnawa coke jan ƙarfe sulfuric acid kunnawa Semi-haske nickel nickel sealing chromium plating bushe kayayyakin.

(3) Za a iya ɗaukar zanen wutar lantarki a cikin samar da cikakken sarrafa kansa.

(4) gwargwadon yadda abin ya kasance game da shi, launin haske na fim ɗin aluminized mai haske ya fi na electroplating chromium haske.

(5) Dangane da aikin, rufin rufin filastik shi ne shimfidar waje mai launi, yayin da zaɓin lantarki yawanci yawanci shine chromium na ƙarfe, don haka taurin ƙarfe ya fi na resin.

s don juriya na lalata, ana amfani da murfin fenti yawanci. Layer murfin ta fi ta ƙarfe kyau, amma akwai ɗan bambanci kaɗan a tsakanin su a cikin buƙatun samfurin ƙarshe; a yanayin yanayi, zaban lantarki ya fi plating injin, saboda haka yawanci yana buƙatar dogon amfani na waje tare da juriya na yanayi.

A cikin masana'antar kera motoci, akwai kuma tsauraran buƙatu na juriya da zafin jiki na ƙasa, zafi da zafi, shafa mai da sauran su.

(6) Ana amfani da plating vacuum a masana'antar sadarwa ta lantarki, kamar harsashin wayar hannu, aikace-aikacen mota, kamar kofuna waɗanda ke nuna fitilun mota; ruwa galibi galibi ana amfani dashi don chromium na ado, kamar kayan ƙofar mota. Orofofin ƙofa da sauransu.

(7) Dangane da yanayin bayyanar launuka iri-iri, tsabtace wuri ya fi wadatar lantarki. Za'a iya yin ɗakunan zinare zuwa zinare da sauran launuka masu launi.

(8) gwargwadon farashin sarrafawa, farashin tsabtace yanayi yana sama da na plating na ruwa.

(9) Sharar faranti tsari ne na kare muhalli mai kore tare da ci gaban fasaha mai sauri, yayin da zaɓin zaɓin ruwa tsari ne na gargajiya tare da gurɓataccen gurɓataccen yanayi, kuma masana'antar tana iyakance ta tasirin manufofin ƙasa.

(10) Ga aikin fesawa (aikin madubin azurfa) wanda yanzunnan ya fito. Tsarin shi ne rage gurɓataccen filastik da kayan share fage na musamman na nishaɗi na Nano-fesa ruwan tsarkake ruwa.

Wannan fasaha na iya haifar da tasirin madubi akan fuskar filastik. Hakanan tsari ne mai tsabtace muhalli. Tsarin farko da na ƙarshen sune iri ɗaya da zaran injin buɗaɗɗen wuri, amma tsaka tsaka kawai.

An maye gurbin Alminin ta madubin feshin azurfa, amma aikin fasaha na yanzu na wannan aikin ba za a iya kwatanta shi da zanen ruwa da abin ɗaki ba. Ana iya amfani da shi ne kawai zuwa kayan aikin hannu waɗanda basa buƙatar bayyanuwa da aiki.

Layin samarwa

Vacuum plating na'urorin don filastik sassa

Roba electroplating samar line

Idan kuna da samfuran tare da sassan filastik da aka zaɓa ko ɓangarorin filastik masu haske don Allah tuntube mu.